Get the free welder performance qualification certificate

Show details

WeldOffice printout sample ASHE WPA C-spec P.O. Box 27604, Concord, California 94527 (877) 977-7999 ASHE Section IX — Welder Performance Qualification (WPA) Created with WeldOffice WPA Module Welder's

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign

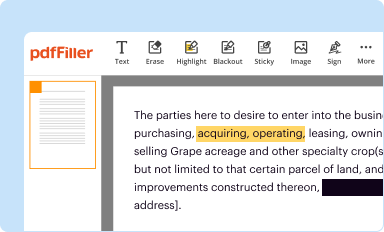

Edit your welder performance qualification certificate form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

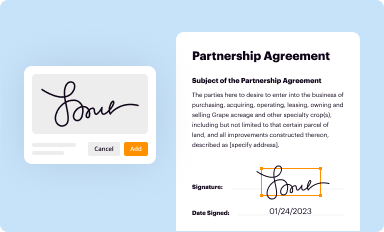

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

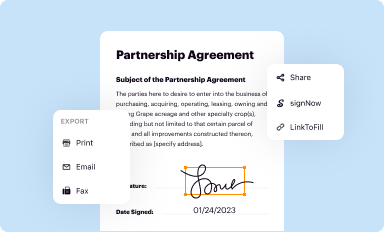

Share your form instantly

Email, fax, or share your welder performance qualification certificate form via URL. You can also download, print, or export forms to your preferred cloud storage service.

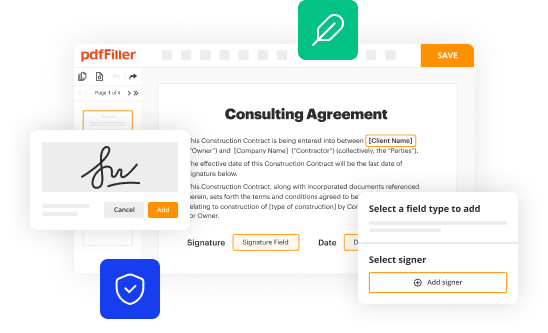

Editing welder performance qualification certificate online

To use our professional PDF editor, follow these steps:

1

Sign into your account. If you don't have a profile yet, click Start Free Trial and sign up for one.

2

Prepare a file. Use the Add New button. Then upload your file to the system from your device, importing it from internal mail, the cloud, or by adding its URL.

3

Edit asme welder performance qualification record. Add and change text, add new objects, move pages, add watermarks and page numbers, and more. Then click Done when you're done editing and go to the Documents tab to merge or split the file. If you want to lock or unlock the file, click the lock or unlock button.

4

Save your file. Choose it from the list of records. Then, shift the pointer to the right toolbar and select one of the several exporting methods: save it in multiple formats, download it as a PDF, email it, or save it to the cloud.

It's easier to work with documents with pdfFiller than you could have ever thought. You may try it out for yourself by signing up for an account.

How to fill out welder performance qualification certificate

How to Fill out Welder Performance Qualification Certificate:

01

Gather all the required information and documentation needed for the certificate, such as the welder's personal details, employer information, and welding procedure specifications.

02

Review the specific requirements and criteria set forth by the relevant standards and regulations for the welder performance qualification process.

03

Fill in the welder's personal information accurately, including their full name, contact details, and any identification numbers or certifications they hold.

04

Provide the necessary details about the employer or the welding company, including their name, address, and contact information.

05

Indicate the specific welding procedure specifications, such as the welding process, base material, filler material, and any applicable preheat or post-weld heat treatment requirements.

06

Include the details about the welding position and joint configuration that the welder is qualified for, specifying whether it is a fillet weld, groove weld, or other types of welds.

07

Document the specific welding performance test results, including the type of test performed (e.g., bend test, radiographic examination, etc.), the test specimen details, and the acceptance criteria.

08

Record any additional information or remarks necessary for the certification process, such as any limitations or restrictions on the welder's qualifications.

09

Sign and date the certificate, ensuring that both the welder and the responsible authority or certifying body have duly signed off on the document.

10

Keep a copy of the completed certificate for the welder's records and submit the original to the appropriate authority or organization requiring the qualification certificate.

Who Needs Welder Performance Qualification Certificate:

01

Welders working in industries where welding performance qualifications are mandated, such as construction, manufacturing, or engineering.

02

Employers or welding companies seeking to ensure their welders meet the required standards and regulations for specific welding projects.

03

Regulatory bodies, government agencies, or industry organizations responsible for overseeing and enforcing welding standards and qualifications.

04

Contractors or subcontractors involved in bidding for welding projects that require welder performance qualifications.

05

Inspectors or quality control personnel responsible for verifying the qualifications of welders on various construction sites or industrial projects.

06

Welding instructors or educators who need to provide proof of qualifications for their students or trainees.

07

Welding professionals or individuals looking to enhance their employability and job prospects by obtaining recognized welder performance qualifications.

08

Individuals involved in international welding projects requiring compliance with specific welding standards and certifications.

Video instructions and help with filling out and completing welder performance qualification certificate

Instructions and Help about welder performance qualification certificate

Fill form : Try Risk Free

People Also Ask about welder performance qualification certificate

What is the difference between welder qualification and welder certification?

How often does a qualified welder need to requalify?

How long is a welder qualification valid for?

How do I get a WPQ certificate?

How long does a welder performance qualification last?

How long does a welder qualification test remain in effect?

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

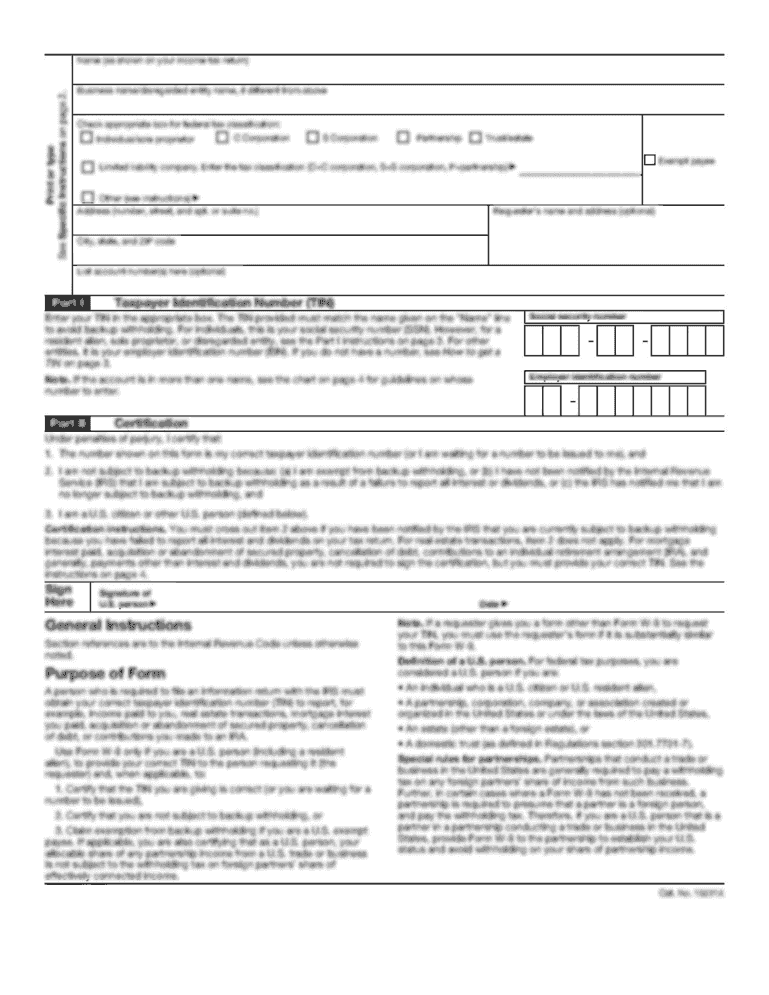

What is welder performance qualification certificate?

A Welder Performance Qualification Certificate is a document that confirms a welder's ability to produce satisfactory welds according to specific industry standards and codes. It is obtained after successfully completing a welding performance test, which typically includes demonstrating proficiency in various welding techniques, equipment handling, and meeting specific quality criteria.

The certificate serves as evidence of a welder's competence and is often required by employers, contractors, or certification bodies to ensure that a welder meets the necessary qualifications to perform specific welding tasks. It helps in demonstrating a welder's skills and knowledge in a particular welding process, joint configuration, material thickness, and welding positions.

Welder performance qualification certificates typically include information such as the welder's name, date of qualification, welding process and technique used, type and thickness of materials welded, positions, and any limitations or restrictions associated with the certification. It is usually valid for a specific period, after which the welder may be required to retest or renew their certification.

Who is required to file welder performance qualification certificate?

Welders are typically required to file a welder performance qualification certificate. This certificate documents that the welder has successfully completed a welding performance test and is capable of producing welds that meet the required standards and codes.

How to fill out welder performance qualification certificate?

To fill out a welder performance qualification certificate, you need to follow these steps:

1. Start by gathering all the necessary information required to complete the certificate, such as the welder's name, identification number, and contact details.

2. Identify the welding process for which the certificate is being issued, such as shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW), or gas metal arc welding (GMAW).

3. Indicate the type of joint being welded, such as butt joint, fillet joint, or groove joint.

4. Specify the welding position for which the welder is being qualified, such as flat position, horizontal position, or vertical position.

5. Mention the welding procedure specification (WPS) that the welder followed during qualification. This includes details such as welding parameters (current, voltage, travel speed), base metal type, electrode or filler wire type, and any specific preheating or post-weld heat treatment requirements.

6. Document the test results from the welding performance qualification test. This may include visual inspection results, mechanical test results, and any radiographic or ultrasonic examination findings. Include the date when the test was conducted.

7. Provide a space for the authorized inspector or the responsible welding engineer to sign and confirm the qualification of the welder. This signature indicates that the welder has successfully met all the necessary requirements for the specific welding process, joint type, position, and WPS.

8. Include the date of issue and any expiry date if applicable. Welder performance qualification certificates usually have a limited validity period, after which the welder may need to undergo requalification.

9. Print multiple copies of the completed certificate, keeping one in the welder's personnel file, and providing additional copies as may be required by contractors, employers, or certification bodies.

Remember to check any specific requirements or format guidelines provided by the relevant welding codes, standards, or certification authorities in your region to ensure complete and accurate completion of the welder performance qualification certificate.

What is the purpose of welder performance qualification certificate?

The purpose of a welder performance qualification certificate is to certify that a welder has demonstrated the necessary skills and proficiency in performing specific welding tasks according to established standards and specifications. This certificate serves as a validation of the welder's ability to consistently produce welds of required quality and structural integrity. It is often required by employers, contractors, and regulatory bodies as evidence of a welder's competence and suitability for performing specific welding jobs.

What information must be reported on welder performance qualification certificate?

The information that must be reported on a welder performance qualification certificate may vary depending on industry standards and specific requirements, but generally it includes the following information:

1. Welder's name and unique identification number or code.

2. Date of qualification.

3. Welding process used for qualification (e.g., shielded metal arc welding, gas metal arc welding, etc.).

4. Welding position(s) qualified in (e.g., flat, horizontal, vertical, overhead).

5. Base metal(s) and thickness(es) qualified for welding.

6. Filler metal(s) and electrode(s) used for qualification.

7. Welding procedure specifications (WPS) used for qualification, including any essential variables (such as welding current, voltage, travel speed, etc.).

8. Test parameters and results, including destructive or non-destructive testing methods employed (such as radiographic, ultrasonic, liquid penetrant, bend test, etc.).

9. Qualification range, which specifies the range of variables (e.g., thickness, diameter, groove angle, etc.) within which the welder is qualified to perform.

10. Certification expiration date, indicating the duration of the qualification.

11. Signature and stamp of the certifying authority, validating the welder's qualification.

It is important to note that requirements may vary based on the specific welding codes and standards applicable to the industry or project. It is always recommended to consult the applicable welding code or standard to ensure compliance.

What is the penalty for the late filing of welder performance qualification certificate?

The penalty for the late filing of a welder performance qualification certificate may vary depending on the specific regulations and requirements of the relevant jurisdiction or industry. It is advisable to consult the governing body or regulatory authority for accurate information on penalties related to late filings.

How can I get welder performance qualification certificate?

It's simple using pdfFiller, an online document management tool. Use our huge online form collection (over 25M fillable forms) to quickly discover the asme welder performance qualification record. Open it immediately and start altering it with sophisticated capabilities.

How do I make changes in wpq format?

With pdfFiller, the editing process is straightforward. Open your welder performance qualification certificate in the editor, which is highly intuitive and easy to use. There, you’ll be able to blackout, redact, type, and erase text, add images, draw arrows and lines, place sticky notes and text boxes, and much more.

Can I create an electronic signature for the welder performance qualification certificate in Chrome?

Yes. You can use pdfFiller to sign documents and use all of the features of the PDF editor in one place if you add this solution to Chrome. In order to use the extension, you can draw or write an electronic signature. You can also upload a picture of your handwritten signature. There is no need to worry about how long it takes to sign your asme welder performance qualification record.

Fill out your welder performance qualification certificate online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Wpq Format is not the form you're looking for?Search for another form here.

Keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.