Get the free Ultrasonic Assembly Systems - Cemausa

Show details

Ultrasonic Assembly Systems2000 SERIES 2000 Series Integrated Ultrasonic Plastic Welders IN/IN+ 1100 and 2200 Watts General Description Bran sons 2000 Series Integrated Welders are self-contained

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign

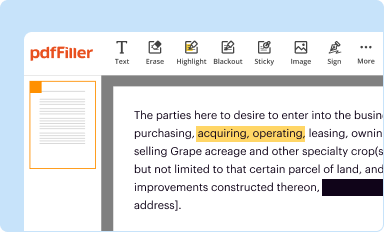

Edit your ultrasonic assembly systems form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

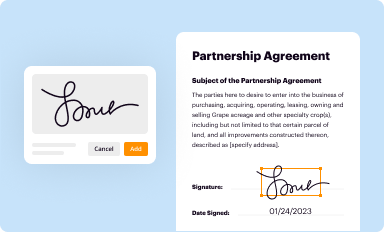

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your ultrasonic assembly systems form via URL. You can also download, print, or export forms to your preferred cloud storage service.

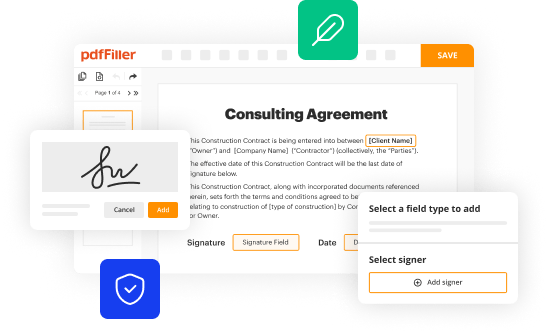

How to edit ultrasonic assembly systems online

Follow the steps below to benefit from a competent PDF editor:

1

Log in. Click Start Free Trial and create a profile if necessary.

2

Upload a document. Select Add New on your Dashboard and transfer a file into the system in one of the following ways: by uploading it from your device or importing from the cloud, web, or internal mail. Then, click Start editing.

3

Edit ultrasonic assembly systems. Replace text, adding objects, rearranging pages, and more. Then select the Documents tab to combine, divide, lock or unlock the file.

4

Save your file. Choose it from the list of records. Then, shift the pointer to the right toolbar and select one of the several exporting methods: save it in multiple formats, download it as a PDF, email it, or save it to the cloud.

With pdfFiller, it's always easy to work with documents.

How to fill out ultrasonic assembly systems

How to fill out ultrasonic assembly systems

01

Before starting, gather all the necessary components for the ultrasonic assembly system, including the main unit, power supply, transducer, wiring, and control panel.

02

Ensure that the power supply is turned off before connecting any components.

03

Begin by connecting the transducer to the main unit using the provided wiring. Make sure the connections are secure and properly aligned.

04

Connect the control panel to the main unit using the appropriate cables. Double-check the connections to ensure they are tight.

05

Once all the components are connected, carefully turn on the power supply and the main unit. Check for any error codes or warning indicators that may require troubleshooting.

06

Adjust the settings on the control panel as per the desired requirements for the ultrasonic assembly process, such as frequency, power, and duration.

07

Place the objects or materials to be assembled using the ultrasonic system in the correct position. Ensure they are positioned securely and properly aligned.

08

Activate the ultrasonic assembly process by pressing the appropriate buttons or switches on the control panel.

09

Monitor the assembly process closely, making sure there are no deviations or issues. Adjust the settings if necessary.

10

Once the assembly process is complete, turn off the power supply and disconnect all the components. Properly store the ultrasonic assembly system for future use.

Who needs ultrasonic assembly systems?

01

Ultrasonic assembly systems are often used in industries that require efficient and precise bonding or welding of materials. Some sectors that commonly utilize ultrasonic assembly systems include:

02

- Automotive industry for assembling plastic components in cars.

03

- Electronics industry for bonding wires, connectors, and components.

04

- Medical industry for sealing medical devices and packaging.

05

- Packaging industry for sealing and cutting plastic or fabric materials.

06

- Textile industry for bonding synthetic fabrics.

07

- Aerospace industry for joining lightweight materials.

08

These are just a few examples, but essentially, any industry that requires reliable and high-quality assembly or bonding can benefit from ultrasonic assembly systems.

Fill form : Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I edit ultrasonic assembly systems from Google Drive?

It is possible to significantly enhance your document management and form preparation by combining pdfFiller with Google Docs. This will allow you to generate papers, amend them, and sign them straight from your Google Drive. Use the add-on to convert your ultrasonic assembly systems into a dynamic fillable form that can be managed and signed using any internet-connected device.

Can I create an eSignature for the ultrasonic assembly systems in Gmail?

You can easily create your eSignature with pdfFiller and then eSign your ultrasonic assembly systems directly from your inbox with the help of pdfFiller’s add-on for Gmail. Please note that you must register for an account in order to save your signatures and signed documents.

How do I complete ultrasonic assembly systems on an Android device?

Use the pdfFiller mobile app and complete your ultrasonic assembly systems and other documents on your Android device. The app provides you with all essential document management features, such as editing content, eSigning, annotating, sharing files, etc. You will have access to your documents at any time, as long as there is an internet connection.

Fill out your ultrasonic assembly systems online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Not the form you were looking for?

Keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.