Get the free sti sp001 annual inspection checklist form

Show details

Apply for a license or permit. Find out how to apply for a license such as a HMO, street trader or taxi license Objecting to a license application. Learn how to make an objection to a license application

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign

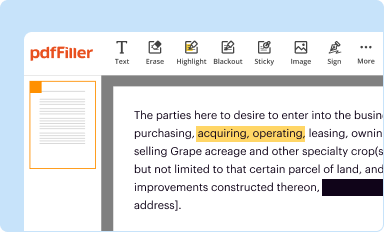

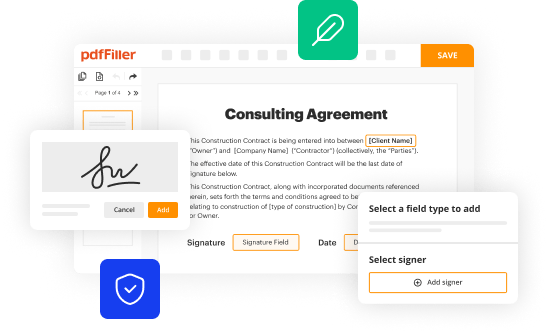

Edit your sti sp001 annual inspection form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

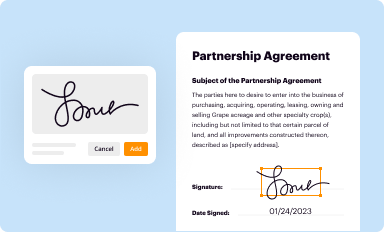

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

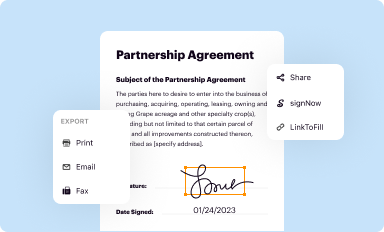

Share your form instantly

Email, fax, or share your sti sp001 annual inspection form via URL. You can also download, print, or export forms to your preferred cloud storage service.

How to edit sti sp001 annual inspection checklist online

Here are the steps you need to follow to get started with our professional PDF editor:

1

Log in. Click Start Free Trial and create a profile if necessary.

2

Upload a file. Select Add New on your Dashboard and upload a file from your device or import it from the cloud, online, or internal mail. Then click Edit.

3

Edit sti sp001 annual inspection checklist form. Rearrange and rotate pages, add new and changed texts, add new objects, and use other useful tools. When you're done, click Done. You can use the Documents tab to merge, split, lock, or unlock your files.

4

Get your file. Select the name of your file in the docs list and choose your preferred exporting method. You can download it as a PDF, save it in another format, send it by email, or transfer it to the cloud.

With pdfFiller, dealing with documents is always straightforward. Try it now!

How to fill out sti sp001 annual inspection

01

First, gather all necessary documentation and information before starting the inspection. This may include previous inspection reports, tank specifications, maintenance records, and any relevant permits or certifications.

02

Start by conducting a thorough visual inspection of the tank and its components. Look for signs of corrosion, leaks, cracks, or any other potential issues. Inspect all exterior surfaces, including the tank shell, supports, piping, and fittings.

03

Inspect the tank interior, if accessible, to check for corrosion, sediment, or any signs of degradation. Use appropriate safety equipment and follow any confined space entry protocols if needed.

04

Document all observations and findings during the inspection. This may include taking photographs, making drawings or sketches, or noting any measurements. Ensure that all documentation is accurate and clear.

05

Perform necessary tests or measurements as specified by the STI SP001 standard or any other relevant regulations. This may include testing for tightness, measuring cathodic protection levels, or verifying tank integrity.

06

Review and compare the inspection findings with the previous inspection reports and maintenance records. Look for any changes or trends that may indicate potential issues or maintenance requirements.

07

Determine the overall condition of the tank and identify any deficiencies or areas that require corrective actions. Evaluate the tank's compliance with the STI SP001 standard and any local or regional regulations.

08

Prepare a detailed inspection report that includes all the collected data, observations, and recommendations. Clearly outline any deficiencies or non-compliance issues and provide suggestions for corrective actions.

09

Submit the inspection report to the appropriate regulatory authorities or stakeholders as required. Ensure that all necessary documentation is provided along with the report.

10

Regularly review and update the tank's inspection and maintenance schedule based on the findings of the annual inspection. Implement any necessary repairs or maintenance activities to ensure the tank's ongoing compliance and integrity.

Who needs STI SP001 annual inspection?

01

Owners or operators of aboveground storage tanks (ASTs) that fall under the jurisdiction of the STI SP001 standard, which includes tanks storing flammable or combustible liquids.

02

Industries or facilities that have ASTs as part of their operations, such as oil and gas, chemical manufacturing, refineries, power generation, or bulk storage facilities.

03

Regulatory bodies or authorities overseeing the storage and handling of hazardous materials, who require periodic inspections to ensure compliance with safety and environmental regulations.

Fill form : Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is sti sp001 annual inspection?

STI SP001 refers to the standard set by the Steel Tank Institute (STI) for the inspection of aboveground storage tanks (ASTs) that store petroleum and alternative fuels. The STI SP001 Annual Inspection is a detailed examination of the tanks to ensure their safe and proper functioning. The inspection typically includes checking the tanks for corrosion, leaks, structural integrity, proper ventilation, spill prevention, and compliance with related regulations and industry standards. It aims to identify and address any issues or potential hazards to ensure the tanks meet the required safety standards and environmental protection measures.

Who is required to file sti sp001 annual inspection?

STI SP001 is a standard for the inspection of aboveground storage tanks for shop-built tanks. Therefore, it is typically the responsibility of the owners or operators of these tanks to file the annual inspection. This may include industrial facilities, petroleum storage terminals, fuel stations, oil refineries, and other entities that use aboveground storage tanks.

How to fill out sti sp001 annual inspection?

To fill out an STI SP001 annual inspection form, follow these steps:

1. Begin by gathering the necessary materials, including the SP001 inspection form, a copy of the most recent inspection report, and any other relevant documentation.

2. Review the inspection requirements outlined in the STI SP001 standard to ensure compliance.

3. Start by entering the general information at the top of the form, such as the tank owner/operator's name, address, and contact details. Include the tank's identification number or name as well.

4. Fill out the inspection date, which should be on or before the due date specified by the standard or regulatory authority.

5. Assess the external inspection section by visually inspecting the tank and associated equipment. Check for any signs of corrosion, leaks, structural damage, or other external issues. Document any findings on the form, including descriptions and measurements.

6. Proceed to the internal inspection section, if required. This may involve scheduling an internal inspection of the tank's interior, performed by a qualified individual. Follow the required steps for assessing the interior conditions, such as measuring sediment and water accumulation, assessing coatings, and inspecting for leaks or other defects. Document the findings and recommendations on the form.

7. Review the cathodic protection system, if applicable. Ensure all required components are functioning properly. Measure and record the protection levels as per the guidelines provided on the form.

8. Check the emergency venting system. Inspect and record the condition of the vents, screens, and flame arrestors.

9. Continue with any other sections or components specified for assessment in the inspection form. This might include overfill prevention equipment, spill prevention equipment, tank foundations, anchor systems, piping, etc. Inspect each component for compliance and document any issues, recommendations, or possible non-conformities.

10. Complete the certification section, including the inspector's name, title, and contact details. Sign and date the form to affirm that the inspection was conducted according to the requirements.

11. Attach any additional documentation, such as photos, measurements, or test certificates, that support the inspection findings or recommendations.

12. Review the completed form to ensure accuracy and completeness. Make any necessary corrections or additions before final submission.

13. Submit the filled-out inspection form to the appropriate authority, tank owner/operator, or regulatory agency, as required.

Remember, specific inspection requirements may differ based on local regulations, the type of tank, and any applicable industry standards. Consult the STI SP001 standard and follow any additional guidelines provided by local authorities for a comprehensive and compliant inspection process.

What is the purpose of sti sp001 annual inspection?

The purpose of the STI SP001 annual inspection is to ensure the integrity and safety of above-ground storage tanks (ASTs) used for storing flammable and combustible liquids. The inspection is conducted in compliance with the SP001 standard set by the Steel Tank Institute (STI) to evaluate the condition, structural integrity, and overall performance of the tanks.

The key objectives of the annual inspection are:

1. Preventing leaks and releases: The inspection identifies any signs of deterioration, corrosion, or damage that may lead to leaks, spills, or releases of hazardous materials.

2. Ensuring compliance: The inspection ensures that the tanks meet the regulatory requirements and standards set by organizations like the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA).

3. Extending the lifespan of the tanks: By identifying and addressing any issues early on, the annual inspection helps to extend the useful life of the tanks, reducing the need for costly repairs or replacements.

4. Enhancing safety: Regular inspections help minimize the risk of accidents, fires, explosions, or environmental contamination that may result from tank failures or malfunctions.

5. Verifying maintenance and operations: The inspection also includes an evaluation of maintenance records, procedures, and operational aspects to ensure they are in line with industry best practices.

Overall, the annual inspection serves as a proactive measure to maintain the overall safety and integrity of above-ground storage tanks and to ensure compliance with regulations and standards.

What information must be reported on sti sp001 annual inspection?

The STI SP001 standard for the inspection of aboveground storage tanks requires reporting of various information during the annual inspection. Some of the key information that must be reported includes:

1. Tank identification details: This includes information such as the tank owner's name, tank location, and tank identification number.

2. Inspection date: The date when the annual inspection was performed.

3. Tank dimensions: This includes the tank's capacity, diameter, and height.

4. Tank construction details: The material of construction, including type of steel, thickness, and welding details.

5. External inspection information: This includes a visual examination of external surfaces, fittings, and appurtenances such as nozzles, vents, and ladders. Any damage, corrosion, or leakage should be noted.

6. Internal inspection information: If the tank is designed for internal inspection, information such as the condition of the tank bottom, shell, appurtenances, and coatings should be reported.

7. Cathodic protection inspection: If the tank has cathodic protection systems installed, the inspection findings should be reported, including the readings of the cathodic protection system.

8. Leak detection system: If the tank has a secondary containment system or a leak detection system, their condition, operation, and any alarms or malfunctions should be reported.

9. Thickness measurements: Thickness measurements of the tank's shell and bottom plates should be reported, along with any signs of corrosion found.

10. Summary and recommendations: A summary of the inspection findings, recommendations for repairs, and any follow-up actions required should be included in the report.

It's important to note that the specific details to be reported may vary depending on the tank's design and the regulations of the specific jurisdiction.

What is the penalty for the late filing of sti sp001 annual inspection?

The specific penalty for the late filing of STI SP001 annual inspection can vary depending on the location and jurisdiction in which the inspection is being conducted. It is advisable to consult the regulatory authority overseeing the inspection process, typically the local environmental or regulatory agency, to determine the specific penalty or fee associated with late filing.

How can I send sti sp001 annual inspection checklist for eSignature?

Once your sti sp001 annual inspection checklist form is complete, you can securely share it with recipients and gather eSignatures with pdfFiller in just a few clicks. You may transmit a PDF by email, text message, fax, USPS mail, or online notarization directly from your account. Make an account right now and give it a go.

How can I get sti sp001 pdf?

With pdfFiller, an all-in-one online tool for professional document management, it's easy to fill out documents. Over 25 million fillable forms are available on our website, and you can find the sti sp001 annual inspection checklist in a matter of seconds. Open it right away and start making it your own with help from advanced editing tools.

How can I edit sti sp001 annual inspection checklist form on a smartphone?

You can do so easily with pdfFiller’s applications for iOS and Android devices, which can be found at the Apple Store and Google Play Store, respectively. Alternatively, you can get the app on our web page: https://edit-pdf-ios-android.pdffiller.com/. Install the application, log in, and start editing sti sp001 pdf right away.

Fill out your sti sp001 annual inspection online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Sti sp001 Pdf is not the form you're looking for?Search for another form here.

Keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.