Get the free Coriolis Dosing Mass Flow Meter Series FMD Operating ...

Get, Create, Make and Sign coriolis dosing mass flow

How to edit coriolis dosing mass flow online

Uncompromising security for your PDF editing and eSignature needs

How to fill out coriolis dosing mass flow

How to fill out coriolis dosing mass flow

Who needs coriolis dosing mass flow?

Coriolis dosing mass flow form: A comprehensive guide

Overview of coriolis dosing mass flow technology

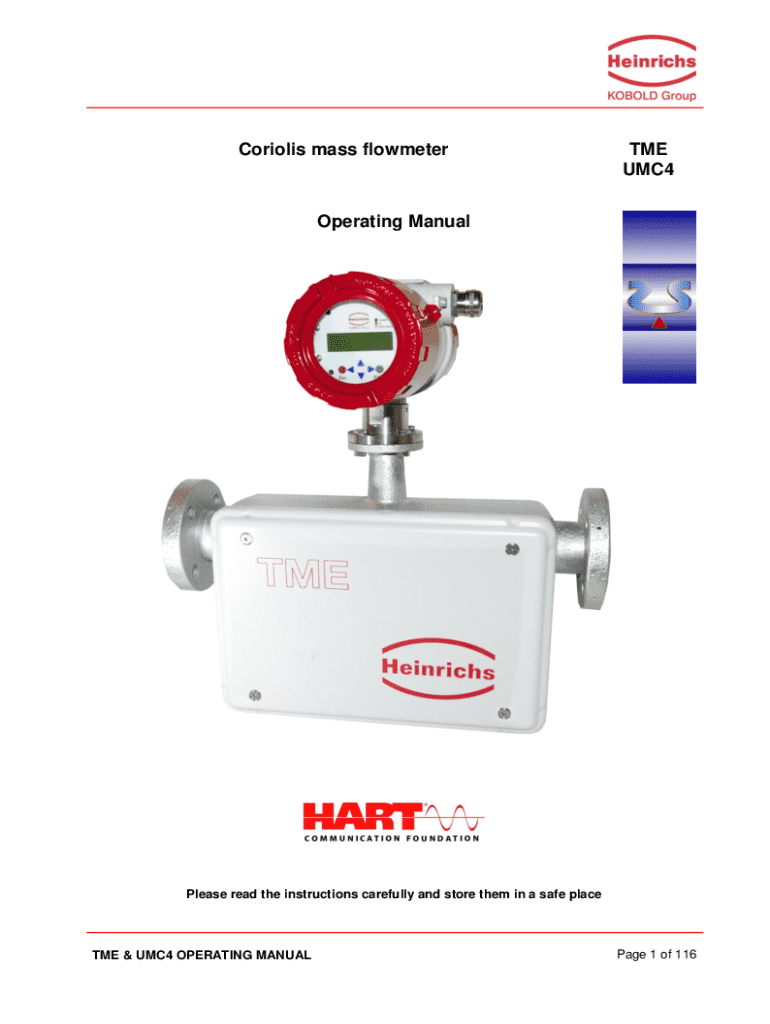

Coriolis dosing mass flow technology is a highly efficient and precise method for measuring mass flow rates of liquids and gases. Utilizing the Coriolis effect, this technology allows for real-time monitoring of flow, ensuring that dosing processes in various industries remain accurate and reliable. The accuracy of these systems makes them indispensable in settings that require strict compliance to measurements, such as pharmaceuticals and food processing.

Coriolis flow meters exhibit key characteristics such as high accuracy, robustness, and the capability to measure density and temperature along with mass flow. These features contribute significantly to their effectiveness in various industrial applications. Accurate dosing is critical as it not only ensures product consistency but also compliance with safety and regulatory standards, which can vary between industries and jurisdictions.

Understanding the coriolis measuring principle

The physics behind the Coriolis measurement principle is grounded in the two-dimensional Coriolis force—an inertial force acting on a mass moving in a rotating system. When a fluid flows through a vibrating tube, its mass flow generates a change in the vibration pattern, which can be quantified and translated into mass flow rate. This elegant method leverages basic physics to achieve high precision.

Mass flow measurement using the Coriolis principle is distinct and advantageous when compared to alternative methods such as volumetric flow or differential pressure measurement. In traditional volumetric measurements, variations in temperature and pressure can lead to inaccurate readings. However, Coriolis meters are unaffected by these factors, ensuring a more reliable dosing solution. This reliability is particularly beneficial in high-stakes environments where precision is paramount.

Design variations of coriolis mass flow meters

Coriolis mass flow meters come in various designs to accommodate different applications. Single-tube systems are generally simpler and less expensive, while dual-tube systems offer enhanced accuracy and are better suited for high-viscosity fluids. These differences in design affect the performance and suitability of the meter for specific applications.

Four-tube measuring systems are a more advanced option, providing greater flexibility and extremely accurate readings. The choice of meter design is influenced by various factors including fluid properties, flow rates, and the application's specific dosing requirements. Customization options are available for many models, allowing industries to tailor meters to their unique production processes.

Applications of coriolis dosing mass flow meters

Industries leveraging Coriolis technology span a wide range, including oil and gas, chemical processing, pharmaceuticals, and food and beverage sectors. Each of these industries requires reliable flow measurement to maintain operational efficiency and compliance with strict regulations.

In oil and gas, enhanced accuracy in fluid delivery is essential for optimizing resource extraction. Chemical processing relies on precise ingredient proportions, minimizing waste and ensuring quality. The pharmaceutical industry mandates strict regulatory compliance in drug production, where any variance in formulation can lead to costly recalls. Meanwhile, the food and beverage sector must meet safety and quality standards to protect public health.

Key features and benefits of using coriolis flow meters

Coriolis flow meters offer several key features and benefits that position them as a premier choice for various applications. High accuracy and repeatability ensure that the dosing process is both stringent and reliable. When systems can provide real-time data monitoring and analytics, businesses can enhance decision-making and operational efficiency.

Additionally, these flow meters are designed to withstand harsh environments, making them durable and reliable under varying conditions. They also offer excellent integration capabilities with existing systems, enabling seamless upgrades and reducing operational disruptions.

Choosing the right coriolis mass flow meter for your needs

Selecting the right Coriolis mass flow meter requires a thorough understanding of your specific needs. Factors such as the fluid type, viscosity, and flow rate will significantly influence the selection process. Consideration should also be given to application requirements such as pressure range and environmental conditions.

Common mistakes include choosing a meter that does not match the application conditions or failing to account for future scalability needs. A systematic approach to identifying the requirements can significantly improve the selection outcome.

How to use the coriolis dosing mass flow form

Using the Coriolis dosing mass flow form effectively requires attention to detail. Step-by-step instructions can simplify this process, ensuring accuracy in data entry. Each section of the form is designed to capture critical information that directly impacts the overall performance of your flow dosing system.

Sections may include general information about operating conditions, fluid properties, and specific requirements. Clearly understanding what essential data needs to be included helps streamline future operations and maintenance. Recommendations for modifying the document can enhance functionality, and pdfFiller's editing features provide excellent flexibility.

Troubleshooting common issues with coriolis dosing systems

Even with accurate and reliable Coriolis dosing mass flow meters, issues can occasionally arise. Frequently asked questions typically include those about meter performance and calibration procedures. Being proactive with maintenance can resolve most discrepancies and ultimately ensure smoother operations.

Flow measurement discrepancies may also occur due to external factors influencing meter readings. Regular calibration, adherence to operating guidelines, and keeping thorough records can help maintain consistency and prevent major issues from escalating.

pdfFiller tools to enhance your flow meter documentation experience

pdfFiller offers a wealth of tools to facilitate the documentation process for your Coriolis dosing mass flow form. Interactive document features allow users to edit, eSign, and share forms easily. This ensures that all stakeholders can access the necessary documents from anywhere, streamlining the operational workflow.

Collaborative tools on pdfFiller enhance team-based document management, creating a centralized space for all project-related documents. The cloud-based platform guarantees that even when team members are not physically together, they can work in unison, promoting efficiency and accuracy in documentation processes.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Where do I find coriolis dosing mass flow?

How do I make changes in coriolis dosing mass flow?

Can I sign the coriolis dosing mass flow electronically in Chrome?

What is coriolis dosing mass flow?

Who is required to file coriolis dosing mass flow?

How to fill out coriolis dosing mass flow?

What is the purpose of coriolis dosing mass flow?

What information must be reported on coriolis dosing mass flow?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.