Get the free PRESTRESSED CONCRETE SLAB BEAM SPANS SPSB- ... - ftp dot state tx

Get, Create, Make and Sign prestressed concrete slab beam

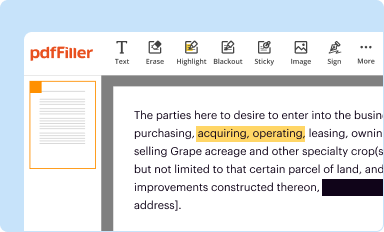

Editing prestressed concrete slab beam online

Uncompromising security for your PDF editing and eSignature needs

How to fill out prestressed concrete slab beam

How to fill out prestressed concrete slab beam

Who needs prestressed concrete slab beam?

Understanding Prestressed Concrete Slab Beam Forms

1. Understanding prestressed concrete slab beams

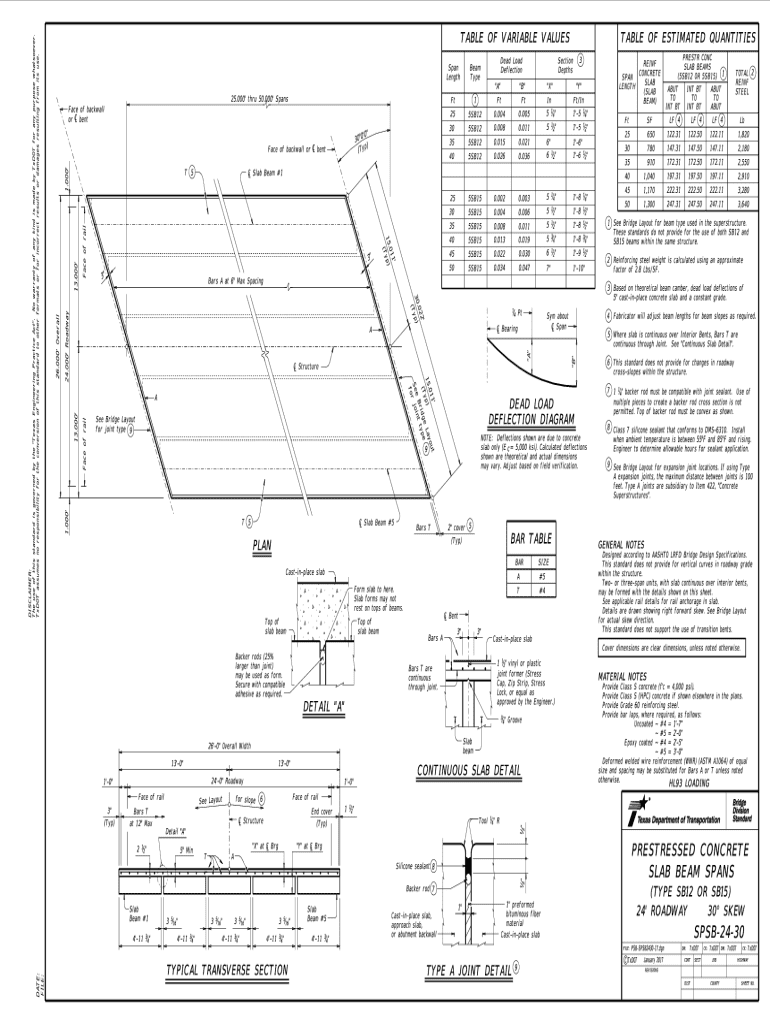

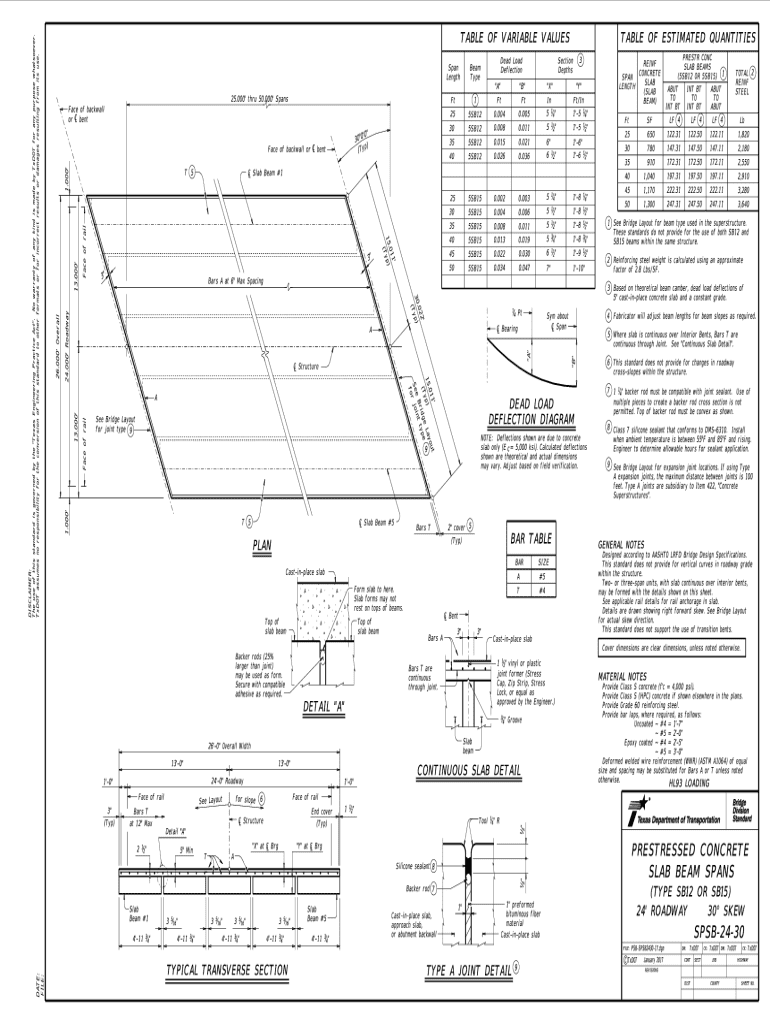

Prestressed concrete is a modern engineering innovation that enhances the performance of concrete structures, particularly slab beams. This technique involves the intentional introduction of stress into concrete elements before they are subjected to external loads. The primary purpose of prestressed concrete slab beams is to improve their load-bearing capacity while minimizing deflections and cracking.

The applications of slab beams in construction are vast, ranging from bridges to multistory buildings. The integration of prestressing allows for longer spans without intermediate supports, thereby offering architectural freedom and reducing material usage, making construction more cost-effective.

2. Key components of prestressed concrete slab beams

The effectiveness of prestressed concrete slab beams largely depends on their core components. The main material utilized is concrete, complemented by prestressing strands that are high-strength steel cables or bars. These materials work together to provide enhanced structural properties when properly designed and installed.

Reinforcement materials, such as epoxy-coated bars and fiber-reinforced additives, can be used to enhance durability. The geometry of slab beams also plays a critical role, as different shapes can influence load distribution and the effectiveness of the prestressing techniques utilized.

3. Design and engineering considerations

Designing prestressed concrete slab beams involves numerous factors, beginning with the loading conditions. Dead loads, live loads, and environmental effects—such as temperature variations and humidity—must all be considered to ensure the design is robust. Span lengths and beam depths also heavily influence the beam's behavior under loads.

To execute proper design calculations, engineers utilize standard criteria that define acceptable limits for stresses and deflections under various loading scenarios. The capacity to accurately compute loads and bending moments is essential in developing safe and economical designs that meet relevant standards.

4. Construction process for prestressed concrete slab beams

The construction of prestressed concrete slab beams begins with thorough pre-construction planning. Site assessments inform the necessary preparation steps, and selecting the right tools and technologies is crucial for ensuring effective project execution. This preparation stage also involves training team members on safety protocols related to working with prestressing equipment.

Once planning is complete, the fabrication process entails casting the beams in controlled environments. This includes proper mixing of concrete, pouring into molds, and curing to achieve the desired strength. The stressing of strands is carefully conducted to ensure that prestress is administered correctly, aiming for optimal performance once installed.

5. Maintenance and inspection

Routine maintenance is vital for ensuring the longevity and structural integrity of prestressed concrete slab beams. Regular inspections should focus on cleanliness and the condition of surface finishes, as well as looking for any signs of cracking or distress that might indicate underlying issues. Timely identification of such signs can assist in mitigating more severe damage down the line.

When repairs are necessary, various methods can be applied depending on the nature and extent of the damage. Common repair techniques may include epoxy injections for crack sealing or re-stressing of strands. If conditions worsen, engaging with professionals for an assessment may be warranted to maintain safety standards.

6. Interactive tools for managing prestressed concrete documents

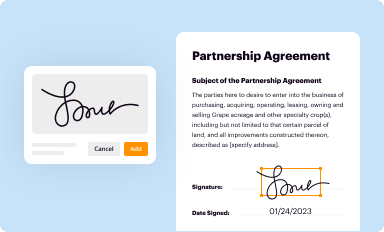

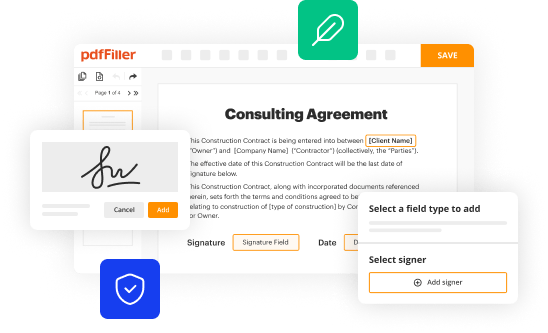

Utilizing document management tools such as pdfFiller can significantly simplify the processes surrounding prestressed concrete slab beams. For individuals seeking to create forms, the platform provides intuitive step-by-step instructions for filling out essential documents needed throughout the design and construction phases.

With collaborative editing capabilities, teams can work in unison, allowing for the seamless incorporation of comments and revisions in real time. Moreover, the secure e-signing options enhance workflow efficiency while ensuring that all files are properly organized and stored in the cloud.

7. Specific instructions for creating templates

Creating effective templates for prestressed concrete slab beams involves outlining essential components to streamline workflows. Key elements include detailed measurements, material specifications, and structural requirements that are universally applicable across projects. This framework aids engineers and contractors in standardizing processes while allowing for project-specific adjustments.

Customization options enable users to tailor their templates according to unique project needs, be it dimensional alterations or the inclusion of various prestressing methods. Integrating these documents with project management tools can further enhance efficiency, linking timelines and milestones with the necessary paperwork.

8. Real-world applications and case studies

Prestressed concrete slab beams have proven their effectiveness in numerous high-profile infrastructure projects around the globe. Notable examples include key bridges and commercial buildings where their use has revolutionized structural possibilities, allowing for wider spans and reducing the need for bulky support columns. Each project provides valuable lessons in design efficiency, material usage, and construction methodologies.

Future trends indicate an increasing reliance on innovative materials and construction techniques in the realm of prestressed concrete. Advancements such as 3D printing and smart materials are poised to enhance the performance of slab beams, pushing the boundaries of design and sustainability in civil engineering.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I edit prestressed concrete slab beam online?

Can I edit prestressed concrete slab beam on an iOS device?

How can I fill out prestressed concrete slab beam on an iOS device?

What is prestressed concrete slab beam?

Who is required to file prestressed concrete slab beam?

How to fill out prestressed concrete slab beam?

What is the purpose of prestressed concrete slab beam?

What information must be reported on prestressed concrete slab beam?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.