Get the free Convolute Deburring Wheels

Get, Create, Make and Sign convolute deburring wheels

Editing convolute deburring wheels online

Uncompromising security for your PDF editing and eSignature needs

How to fill out convolute deburring wheels

How to fill out convolute deburring wheels

Who needs convolute deburring wheels?

Convolute Deburring Wheels Form: A Comprehensive Guide

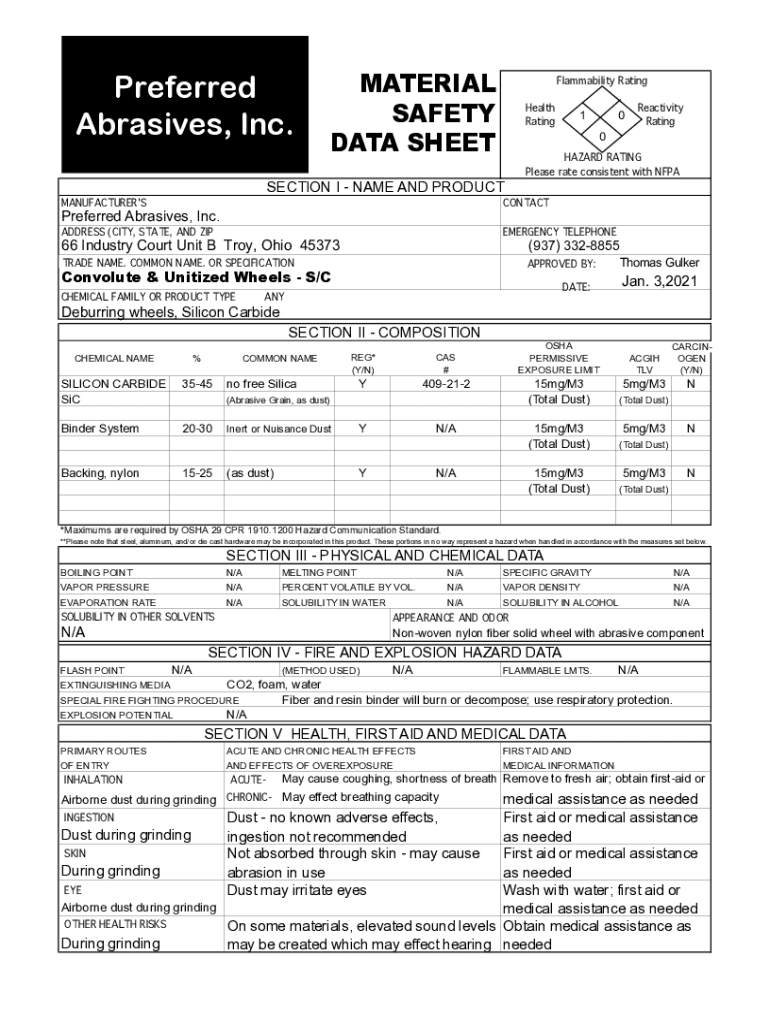

Overview of convolute deburring wheels

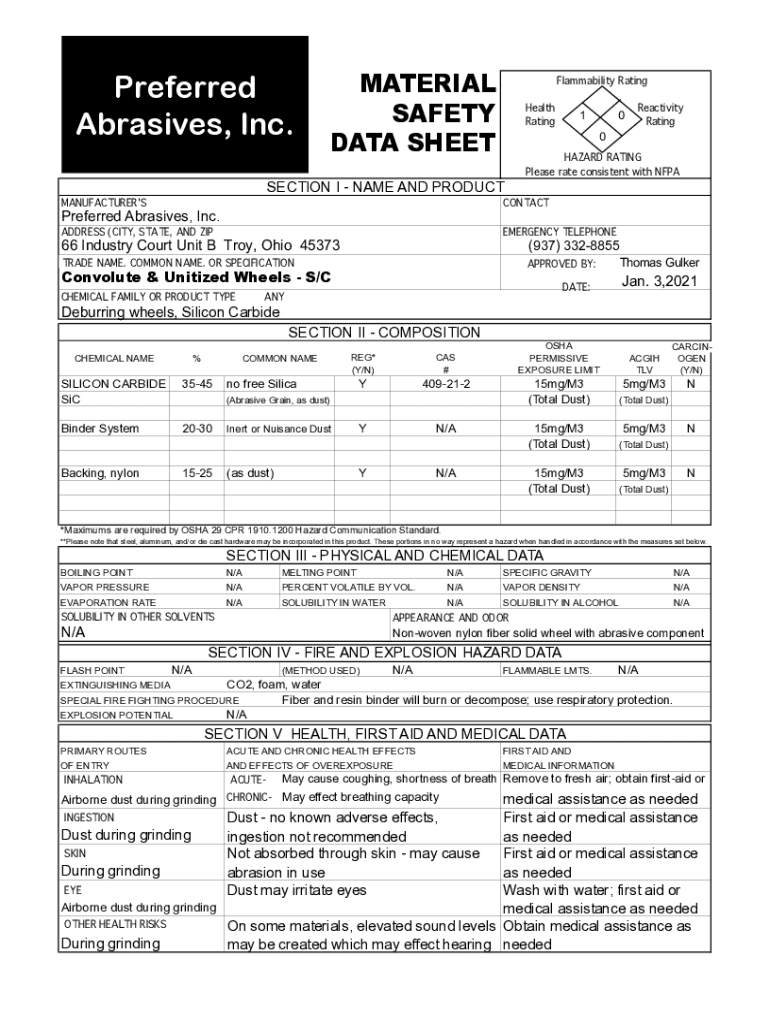

Convolute deburring wheels are essential tools in surface finishing, designed to remove burrs, sharp edges, and improve the overall aesthetic quality of materials. These wheels are made from layered, convoluted materials that provide a protective and cushioning effect, allowing for refined finishing without damaging the underlying surface. Their primary purpose is to ensure safety and improve product performance by creating smooth finishes on various substrates.

Utilizing convolute deburring wheels enhances productivity in industrial applications by minimizing the need for secondary finishing processes. They efficiently handle a variety of workloads, making them ideal for both large scale manufacturing and smaller projects. The versatility of these wheels is one of their significant advantages, allowing them to adapt to different applications, from metalworking to woodworking.

Types of convolute deburring wheels

Convolute deburring wheels are categorized primarily based on their hardness: soft and hard wheels. Soft convolute wheels are more elastic, allowing for gentler finishes, which is ideal for soft materials. Conversely, hard convolute wheels provide a more aggressive approach, making them suitable for tougher materials and heavier deburring tasks.

The material composition of these wheels also plays a critical role in their performance. They are often made from cotton or synthetic fibers, each providing distinct characteristics. Cotton wheels are known for their flexibility and cushioning, perfect for delicate finishing. Synthetic fiber wheels, on the other hand, offer durability and stability for more demanding work.

Key features of convolute deburring wheels

One crucial feature of convolute deburring wheels is grit size, which significantly impacts the finishing process. Available in various grit sizes, ranging from coarse to fine, they enable operators to choose the appropriate wheel according to the material requirements and the desired finish quality. Coarse grits are ideal for heavy burr removal, while fine grits provide a smoother finish.

In addition to grit size, wheel diameter and thickness must also be considered. A larger wheel diameter can cover more area quickly, while thickness influences durability and how deep the wheel can penetrate the workpiece. Understanding these specifications ensures that users select the most suitable wheel for their specific applications, maximizing efficiency during the deburring process.

Choosing the right convolute deburring wheel

Selecting the correct convolute deburring wheel is critical for achieving the best results. There are several key factors to consider, including the material being worked on. Different materials, such as metals, plastics, or wood, have varying characteristics that influence the choice of wheel hardness, grit, and composition. Understanding these traits will guide users to make the right decisions.

Desired finish quality is another vital consideration. For instance, achieving a high-gloss finish may require finer grits and soft wheels, whereas a more rustic look may be effectively attained with coarser wheels. Additionally, compatibility with existing machines is crucial. Convolute deburring wheels need to fit the specific models and specifications of deburring equipment employed in your workspace.

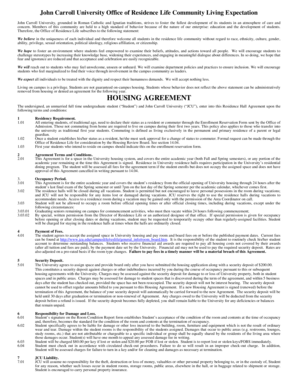

Best practices for using convolute deburring wheels

Before using convolute deburring wheels, it’s essential to perform a pre-use inspection. Check for any wear, damage, or abnormalites in the wheel which may affect performance. A thorough examination ensures that wheels operate safely and effectively during the deburring process.

Proper mounting techniques also play a significant role in achieving optimal results. Ensure that wheels are securely mounted to avoid slips during use, which can lead to inaccurate deburring or even accidents. Moreover, adhering to recommended operating speeds helps prevent overheating and extends the lifespan of the wheel, thereby maximizing productivity.

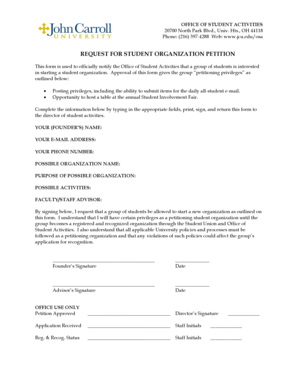

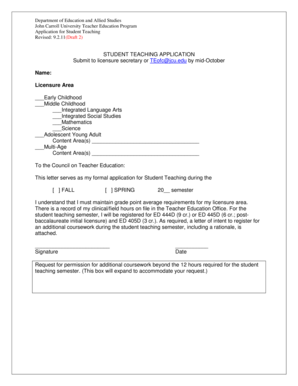

Step-by-step guide: filling out the convolute deburring wheels order form

Accessing the convolute deburring wheels order form on pdfFiller is straightforward and user-friendly. Begin by navigating to the specific order form accessible through the pdfFiller platform. Once there, ensure you have all the necessary information at hand to complete the form accurately.

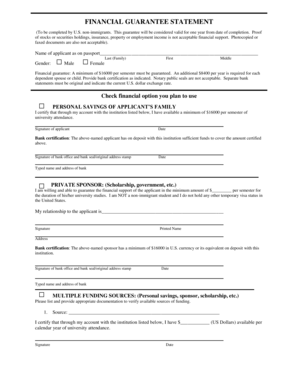

The order form consists of various sections that must be filled out diligently. The first section requires personal information, which includes your name, contact details, and business name if applicable. Next, select the type of deburring wheels you require, making sure to choose between soft and hard options and specify the material needed. Input quantity and pricing based on your project requirements, and finally, choose your preferred payment method to finalize the process.

Tips for effective document management with pdfFiller

To maximize your experience with pdfFiller, embracing best practices for document management is paramount. Use collaborative features to edit and discuss forms with your team, allowing for real-time adjustments and feedback. The platform's eSigning features are particularly valuable for obtaining quick approvals, simplifying workflows across your operations.

Moreover, take advantage of the storing and access functionalities that pdfFiller offers. No matter your location, you can always retrieve, edit, or manage your forms efficiently, enhancing accessibility while ensuring all documentation is organized and secure.

Troubleshooting common issues with deburring wheels

Identifying surface defects during the deburring process is essential for ensuring quality finishes. Common issues such as uneven surfaces, persistent burrs, or material tearing can arise when the appropriate wheel type or grit size is not used. Adjusting your technique is critical; different operating speeds or pressure can yield distinct results.

Furthermore, it's crucial to avoid common mistakes. Ensure you are not using outdated wheels, as they might not provide the expected results. Using the wrong wheel type for a specific application can also lead to sub-optimal outcomes. Training your team to recognize these issues will enhance operational efficiency and product quality.

Additional accessories for convolute deburring wheels

To enhance the functionality and safety of convolute deburring wheels, several accessories are recommended. Backing pads play a crucial role in providing support to the wheels, ensuring durability and optimal performance during application. They also help in distributing pressure evenly across the wheel surface, reducing the risk of damage.

Protective gear, such as gloves and safety goggles, is paramount during the deburring process. These accessories safeguard operators from potential injuries and ensure a safe working environment. Additionally, proper maintenance and storage of deburring wheels extend their lifespan, ensuring top-notch performance.

FAQs on convolute deburring wheels

When considering the applications of convolute deburring wheels, users often inquire about the most common applications. These include metal deburring, polishing, and finishing wood surfaces, among others. Each application demands a unique approach based on the material and finish type desired.

Additionally, many ask how to identify the right wheel for their project. Factors such as grit size, wheel hardness, and material compatibility guide users in making informed decisions. Lastly, the expected lifespan of a convolute deburring wheel varies based on usage, conditions, and maintenance but typically ranges from several hours to several hundred hours, emphasizing the importance of proper care.

Case studies: successful applications of convolute deburring wheels

Analyzing real-life examples demonstrates the effectiveness of convolute deburring wheels across various industries. For instance, a metal fabrication company implemented soft convolute wheels for delicate metal finishing, significantly reducing surface imperfections and improving the product's overall finish quality. This transition not only enhanced product aesthetics but also led to reduced labor costs due to fewer returns.

Similarly, in the woodworking industry, companies utilizing hard convolution wheels found a remarkable increase in productivity. Deburring time was reduced by nearly 30%, allowing for quicker turnaround times without sacrificing quality. These successful applications showcase the importance of selecting the right tools for specific tasks, illustrating how convolute deburring wheels can lead to operational efficiency.

Contact and support information for pdfFiller users

For users seeking assistance with pdfFiller's services, a variety of customer service channels are readily available. Users can contact support through email, live chat, or by visiting the extensive user community and forums. These resources provide valuable guidance not only for order-related inquiries but also for broader questions regarding the platform's features and functionalities.

Engaging with the pdfFiller community through forums allows users to share insights, troubleshoot common issues, and learn from one another. Whether you are a beginner or an advanced user, these support networks serve as invaluable tools for maximizing your experience with pdfFiller.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I modify convolute deburring wheels without leaving Google Drive?

How do I edit convolute deburring wheels on an iOS device?

How do I complete convolute deburring wheels on an Android device?

What is convolute deburring wheels?

Who is required to file convolute deburring wheels?

How to fill out convolute deburring wheels?

What is the purpose of convolute deburring wheels?

What information must be reported on convolute deburring wheels?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.