Get the free Convolute & Unitized Wheels - SC

Get, Create, Make and Sign convolute unitized wheels

Editing convolute unitized wheels online

Uncompromising security for your PDF editing and eSignature needs

How to fill out convolute unitized wheels

How to fill out convolute unitized wheels

Who needs convolute unitized wheels?

Comprehensive Guide to Convolute Unitized Wheels Form

Overview of convolute unitized wheels

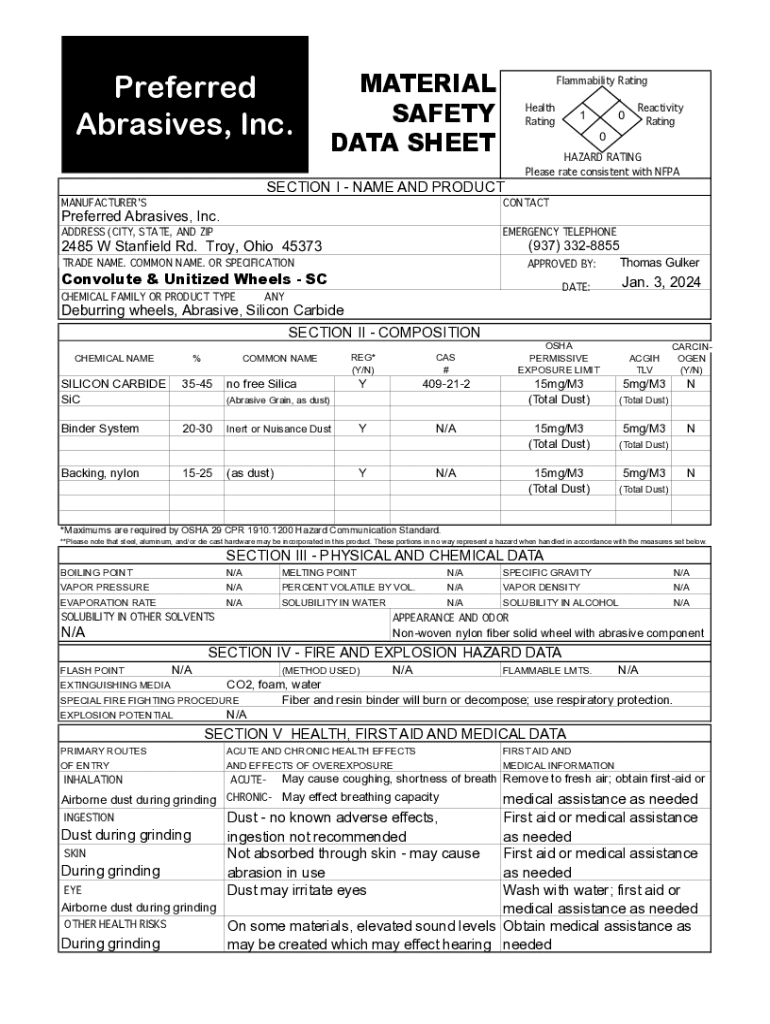

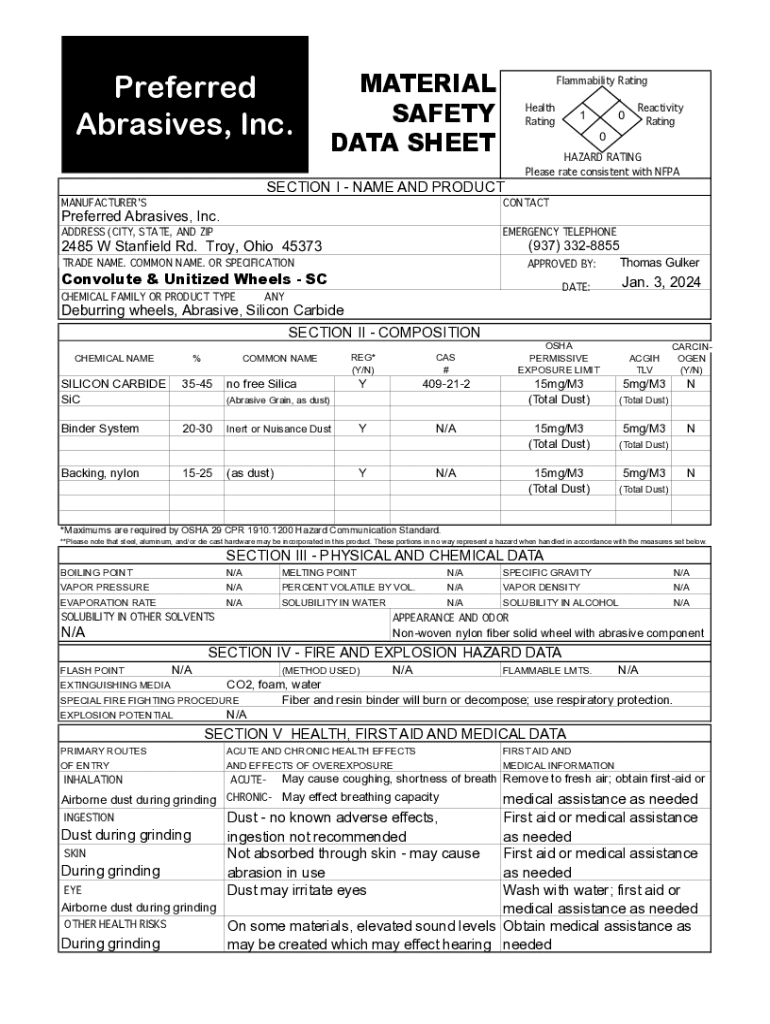

Convolute unitized wheels are specialized abrasives used extensively in various finishing operations. These wheels consist of layers of non-woven fibers infused with abrasive materials, creating a durable and effective tool for grinding, polishing, and de-burring processes. Characterized by their uniform density and structure, they offer consistent results while minimizing the risk of damage to the workpiece.

The key benefits of convolute unitized wheels include their versatility, as they can be utilized for multiple applications ranging from metal fabrication to woodworking. Their soft, yet firm surface allows for precision control, making them ideal for fine finishing tasks. Additionally, they tend to have a longer lifespan compared to traditional grinding wheels, leading to less frequent replacements and ultimately cost savings.

Applications of convolute unitized wheels

Convolute unitized wheels are commonly employed in several industries, including automotive, aerospace, and metalworking. In automotive applications, they serve roles in surface conditioning, preparing surfaces for painting, and achieving the desired finishes on components. Similarly, in aerospace, they are critical for ensuring the smooth surfaces vital for performance and safety.

Their adaptability extends to tasks such as deburring edges on metal parts, finishing stainless steel components, and cleaning welds. The ability to work on various materials, including aluminum, brass, and plastics, further amplifies their usability across different sectors.

Types of convolute unitized wheels

When selecting convolute unitized wheels, it's essential to consider the material composition. The primary materials include non-woven synthetic fibers and abrasive grains such as aluminum oxide or silicon carbide. The choice of material influences the wheel's performance, durability, and suitability for specific applications.

Standard varieties of convolute unitized wheels come in various types based on grit size, density, and intended application. Common grit sizes range from coarse to fine, allowing for a tailored approach depending on the task. For example, coarser wheels are useful for significant material removal, while finer options are designed for polishing and creating smooth finishes. When comparing models in the market, assessing their density can also provide insight into their durability and application-specific performance.

Selecting the right convolute unitized wheel

Choosing the right convolute unitized wheel requires careful consideration of several key factors. First, material compatibility is crucial; for instance, a wheel optimized for metal might not perform well on plastics. Understanding the workpiece material ensures effective cutting and finishing without damaging the surface.

Grit selection plays a vital role, too. Coarser wheels are preferred for heavy material removal and roughing tasks, while finer wheels are ideal for detailed finishing and polishing. Additionally, the size and shape of the wheel should align with the task at hand; whether you're working on large surfaces or intricate details, the right wheel configuration enhances effectiveness.

Common mistakes to avoid include overlooking the workpiece material's characteristics and selecting grit sizes that don't align with the desired finish. These missteps can lead to inefficiencies, increased replacement costs, and poor surface finishes.

How to use convolute unitized wheels

Proper usage of convolute unitized wheels is essential for achieving the desired results and maintaining safety. Follow this step-by-step application guide to ensure effective operation.

Troubleshooting common issues is also crucial. Excessive wear may indicate either too much pressure or incorrect grit choice. If you encounter poor performance, check for damage to the wheel or improper mounting. Vibration during operation can result from an unbalanced setup or a worn wheel; addressing these problems promptly will optimize your workflow.

Advantages of using convolute unitized wheels

The advantages of using convolute unitized wheels are numerous. Their efficiency in various processes translates to faster operations, allowing for significant time savings. Operators report improved work quality, particularly in finishing tasks where consistency is paramount.

Their versatility across applications makes them a go-to choice for multiple tasks including grinding, polishing, and de-burring. The ability to switch seamlessly between different functions reduces the need for multiple tools and simplifies workflows. Additionally, their cost-effectiveness stems from longevity; with less frequent need for replacement, users realize savings over time compared to other solutions.

Comparison with other abrasive tools

When contrasting convolute unitized wheels with grinding wheels, several key differences emerge. Convolute wheels typically offer less aggressive material removal rates, which allows for finer finishes without the risk of damaging the workpiece. Unlike traditional grinding wheels, they are designed for more delicate tasks, making them less likely to produce heat buildup that can deform metal parts.

In comparison to coated abrasives, convolute wheels excel in situations requiring more consistent surface finishes. While coated options can be suitable for aggressive material removal, convolute wheels provide a finer touch, especially beneficial in finishing and polishing stages. There are scenarios, however, where other tools might be more beneficial, such as heavy-duty grinding or when more aggressive cutting action is needed.

Managing and storing convolute unitized wheels

Effective management and storage of convolute unitized wheels are necessary to prolong their lifespan and maintain performance. Best practices include storing wheels in a dry environment, away from direct sunlight and moisture, which can degrade the materials over time.

Implementing an inventory management system helps track usage and replacement needs. This proactive approach allows for timely reordering and ensures you always have the right tools at hand. Furthermore, consider environmentally friendly practices for recycling and disposal options for used wheels, as many components can be repurposed or processed sustainably.

Innovative uses and trends in convolute unitized wheels

Recent developments in material technology are continually enhancing the performance of convolute unitized wheels. Innovations lead to stronger, more adaptable materials that can handle a wider variety of applications and workpiece materials. Additionally, these advancements often result in wheels that produce less waste during operation, aligning with modern sustainability trends.

Emerging applications in industries such as renewable energy and advanced manufacturing highlight the versatility of convolute wheels. From refinishing turbine blades in wind energy systems to precision polishing in aerospace applications, the demand is growing. Furthermore, manufacturers are increasingly focusing on developing eco-friendly options, making convolute wheels more sustainable than ever.

Interactive tools on pdfFiller for managing convolute unitized wheels

pdfFiller offers robust tools for managing documents related to convolute unitized wheels. Users can create and modify procurement, maintenance, and inventory forms seamlessly on a single platform. This capability streamlines operations, reducing time spent on documentation.

Collaborative features within pdfFiller facilitate team efforts in projects involving convolute wheels. Teams can work together efficiently by sharing forms, filling them out collaboratively, and maintaining version control, ensuring everyone stays updated and informed throughout the process.

Final thoughts on the future of convolute unitized wheels

The future of convolute unitized wheels looks promising with forecasts indicating growth in demand across various sectors. As industries continue to evolve, so too will the materials and technologies employed in wheel manufacturing, focusing on enhanced performance and sustainability.

New technologies on the horizon point to even smarter abrasives that may offer real-time monitoring of wear and performance. As we embrace innovative practices in documentation and usage, platforms like pdfFiller will play a critical role in helping users manage the complexities of modern tool and material management efficiently.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I send convolute unitized wheels for eSignature?

Can I create an electronic signature for signing my convolute unitized wheels in Gmail?

Can I edit convolute unitized wheels on an Android device?

What is convolute unitized wheels?

Who is required to file convolute unitized wheels?

How to fill out convolute unitized wheels?

What is the purpose of convolute unitized wheels?

What information must be reported on convolute unitized wheels?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.