Get the free dot 90 day inspection form

Get, Create, Make and Sign

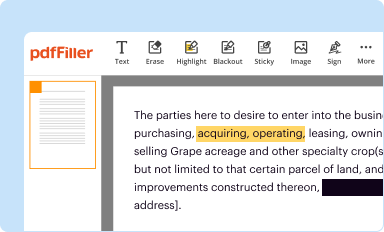

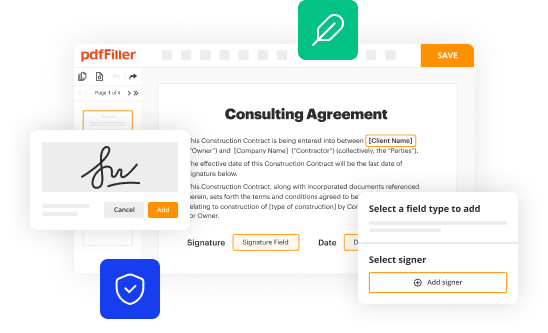

How to edit dot 90 day inspection form online

How to fill out dot 90 day inspection

How to fill out a 90 day bit inspection:

Who needs a 90 day bit inspection:

Video instructions and help with filling out and completing dot 90 day inspection form

Instructions and Help about where do copies of the bit insppection forms go

Hello Rudy Salazar with Calvert calm and welcome to our seventh video in these 8 video series on the basics of the California inspection program now all these steps can be found in this book that I've written it's the only book out there the first one I'm the first one to write a book on this subject, and you could get this at our website at Calvin as well as our e-book which is the e-book version which is actually the best value because the e-book has all the original forms that we use in this whole program, so you can just click and print as you wish with the e-book, and it'll help you administer the business fiction program so now what we're going to cover Oh women when we get started as always our disclaimer I'll make it quick it is your responsibility to know the vehicle code as it pertains to you and your motor and your motor fleet when it comes to the bin spectrum program the bin inspection programs in the vehicle code book so this one's the last year's copy, so it's your responsibility to know that also a jury responsibility to know the d-o-t rules and regulations at the department transportation the Federal Department transportation I'm just a guy on the website that helps people understand the basics ok so let's be friends in let's go on that's my disclaimer ok the 90-day mechanical inspection now as you can see the way I've been teaching this is we've been building up to this whole system here that when you get when you're doing your bit inspection program you should be able to lay this out every time the inspector comes out every two years and so it should be a stress-free situation the longer you're doing this on a daily basis some of it's not daily like once a file folder system on your new driver hiring is done you seal it you put it away but some of this other stuff grows and contracts and again as I'll be saying a lot do not co-mingle well you don't need to be combing and don't call me know anything it just really makes things simple so our 90-day mechanical inspection here we go we're going to start and what we do with this is here's a form that I mean it's available on our website I sell it in 25 packs little packets here and this form is a perfect form there's other 90-day mechanical inspection forms out there that you could use, but my form is designed to be a nice thing for mechanics to follow it step-by-step it's kind of you start outside the trunk, and you work your way under the truck and around the truck but the way this is written is you could use this as a work order or just a 90-day mechanical inspection form and sometimes a lot of times actually when you're doing 90-day mechanical inspection you also do an oil change and lube oil filter which is not part of the 90 day but in this little form here I have a little Aster ix showing and not part of the 90 day, but you can change your oil with this and things like that and then here you just list the mechanic can list everything wrong that they find with the truck the...

Fill chp 90 day inspection form pdf : Try Risk Free

People Also Ask about dot 90 day inspection form

Our user reviews speak for themselves

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Fill out your dot 90 day inspection online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.