Cooling Tower Systems Details Form - A Comprehensive Guide

Overview of cooling tower systems

Cooling towers play a vital role in various industrial and HVAC (Heating, Ventilation, and Air Conditioning) applications by removing excess heat from process water or air. The efficiency of cooling towers significantly impacts system performance, energy costs, and operational sustainability. In regions with prevalent industrial activities, understanding cooling towers becomes essential for regulatory compliance and operational efficiency.

The functionality of cooling towers hinges on their ability to dissipate heat from water, which is then cooled as it circulates through these systems. Common applications include power generation plants, chemical processing, oil refineries, and large commercial buildings. This versatility makes cooling towers an indispensable component in cooling systems across numerous sectors.

Natural draft cooling towers: Operate by using natural convection and gravity to circulate air.

Mechanical draft cooling towers: Utilize fans to increase air flow and improve cooling efficiency.

Wet and dry cooling towers: Vary based on their cooling methods—wet towers use evaporation, while dry towers use heat exchangers.

Essential information on cooling tower registration

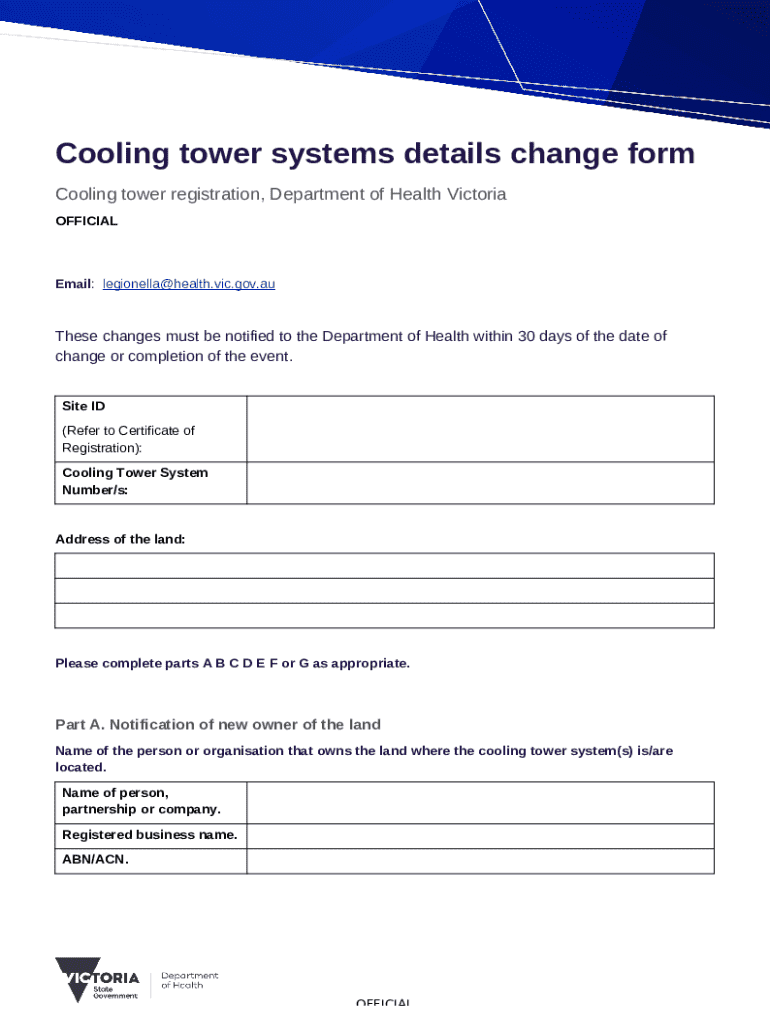

The cooling tower registration form serves an important function by standardizing the documentation process required by municipal and environmental authorities. Completing this form is crucial for compliance with health and safety regulations, particularly those related to legionella disease prevention and control.

Individuals or businesses responsible for operating a cooling tower are typically required to register their systems. Registration is often mandated by local, state, or federal regulations aimed at monitoring the health and safety impacts of cooling towers within communities.

Owners of cooling towers must ensure that their systems are registered with the appropriate authorities.

The registration process varies by jurisdiction, but generally includes the submission of essential information about the tower's design and operation.

Compliance with regulations often includes periodic inspections and the necessity of maintaining operational records.

Steps to complete the cooling tower systems details form

Completing the cooling tower systems details form involves a systematic approach to collecting and submitting relevant information. The following steps will ensure accuracy and compliance:

Gather required documentation: Compile documents such as design specifications, permits, and operational procedures.

Filling out the form: Provide accurate details in sections for general information and technical specifications, ensuring complete information about ownership, location, type of cooling tower, and its design capacity.

Review and edit your form: Before submission, thoroughly check for errors using tools like pdfFiller that allow easy editing.

Submitting the form: Understand the accepted submission methods, such as online platforms or mailing physical copies, and be aware of response times and next steps.

Managing cooling tower systems documentation

It’s essential to maintain organized documentation for cooling tower operations. Utilizing platforms like pdfFiller facilitates effective document management, storing your forms in the cloud for easy access. By having a systematic organization, operators can quickly retrieve required records for audits and compliance inspections.

With robust document management tools, teams can collaborate effectively, sharing crucial data and updates among members. This streamlining process benefits not only maintenance protocols but also enhances communication regarding regulatory obligations.

Organize documents: Keep all paperwork related to the cooling tower in designated folders according to relevant categories.

Utilize cloud-based platforms: Ensure document accessibility from anywhere, fostering collaboration among team members responsible for tower management.

Maintain version control: Track changes made to documents, which is vital for ensuring compliance with evolving regulations.

Interactive tools available on pdfFiller for cooling tower management

pdfFiller provides an impressive array of interactive tools designed to simplify cooling tower documentation. One key feature includes e-signature capabilities that facilitate swift approval processes, allowing users to sign off on essential documents without the hassle of printing and scanning.

Furthermore, users can easily edit PDFs, ensuring that any adjustments needed to forms or specifications can be made promptly. Keeping track of document status has also been improved through pdfFiller’s features, allowing operators to stay informed about their submissions.

E-signature features: Securely sign documents electronically to expedite approvals.

Editing PDFs easily: Modify forms on-the-go, saving time during crucial operational periods.

Tracking document status: Monitor submissions and updates in real-time to ensure proper follow-up.

Notifications and updates

Staying compliant means being proactive about your cooling tower’s status, particularly for notifications related to decommissioning or removal. This process requires clear communication with regulatory authorities, and operators must notify them promptly to avoid penalties.

Additionally, operators must keep their registration details up-to-date. Changes in ownership or operation should be documented and reported immediately. Furthermore, if legionella detection occurs, it is critical to report this diagnosis quickly to comply with health and safety regulations.

Notify for decommission or removal: Follow the regulatory guidelines provided for notification timelines.

Changing registration details: Submit any updated information regarding operation or ownership.

Reporting legionella detection: Understand the procedure for immediate reporting to mitigate health risks.

Risk management plans for cooling towers

Risk management is a critical aspect of cooling tower operations. Operators must conduct thorough risk assessments to identify potential hazards related to cooling tower operation, including biological, chemical, and mechanical risks. A proactive approach to risk assessment not only helps in ensuring compliance but also contributes to maintaining a safe and efficient cooling environment.

Implementing an auditing process can help ensure that all systems adhere to both internal policies and external regulations. Regular audits enable operators to identify weaknesses and develop actionable strategies to improve compliance and operational safety.

Conduct necessary risk assessments: Evaluate environmental impacts and health hazards associated with tower operations.

Implement auditing processes: Regularly audit cooling towers to ensure compliance with operational standards and regulations.

Develop common risk factors and mitigation strategies: Address common threats such as legionella and heat stress proactively.

Common fees and refund policies

Understanding the fees associated with cooling tower registration and compliance is crucial for effective budgeting. Common fees may include registration fees, inspection charges, and potential penalties for non-compliance. Knowing these costs can aid in financial planning over the lifecycle of cooling tower operations.

Furthermore, knowing the refund eligibility criteria and procedures is equally important. In cases where cooling towers are decommissioned or funds are mistakenly paid, operators should be prepared to navigate the refund process efficiently.

Overview of associated costs: Be aware of fees for registration, follow-up inspections, and potential fines.

Understanding refund eligibility: Familiarize yourself with the refund process in your jurisdiction.

Maintain records of all payments and correspondence to facilitate any refund requests.

Frequently asked questions about cooling tower systems

Operators often have queries regarding the cooling tower registration process. Understanding common inquiries can alleviate concerns and streamline compliance efforts. For instance, questions often arise about the types of data needed for registration, potential penalties for failure to register, and methods of documenting maintenance practices.

Troubleshooting any issues with filling out the form can also be critical for seamless operations. Familiarity with best practices for cooling tower maintenance can further enhance performance and compliance.

Common inquiries about the registration process: Familiarize with the range of information required for form completion.

Troubleshooting filling out the form: Be prepared to seek clarification for any ambiguous sections.

Best practices for cooling tower maintenance: Implement regular inspection and cleaning schedules to comply with regulations.

Contact information for assistance

For individuals and teams needing assistance with the cooling tower systems details form, support channels are readily available. Communicating effectively with knowledgeable team members can streamline both registration and compliance processes.

Users can reach out via email, telephone support, or live chat on pdfFiller’s website. Additionally, keeping informed about office locations and operational hours can help facilitate timely communication.

Support channels: Utilize email, phone, and live chat for prompt assistance.

Find office locations and operational hours to ensure you connect during service times.

Prepare specific queries in advance to maximize the effectiveness of your communication.

Community engagement

Engagement within the community is essential for continued growth and improvement. Connecting with industry peers and learning from their experiences can enhance best practices in cooling tower management.

Stay informed and involved by following official company profiles on social media platforms such as Facebook, Twitter, and Instagram. Sharing your feedback and insight contributes to a vibrant community focused on safe and effective cooling tower operations.

Follow us on social media: Join our Facebook, Twitter, and Instagram communities.

Leave us feedback: Share your experiences to enhance our service and community knowledge.