Get the free Cooling Tower or Warm Water Storage System Application to Vary Registration

Get, Create, Make and Sign cooling tower or warm

Editing cooling tower or warm online

Uncompromising security for your PDF editing and eSignature needs

How to fill out cooling tower or warm

How to fill out cooling tower or warm

Who needs cooling tower or warm?

Cooling tower or warm form: A comprehensive how-to guide

Understanding cooling towers

Cooling towers are vital components in many industrial and commercial systems, designed to remove excess heat from water that has been heated during various processes. These structures help maintain optimal operating temperatures, ensuring machinery and systems operate efficiently, ultimately leading to enhanced productivity and energy savings across sectors such as manufacturing, power generation, and HVAC.

The primary function of cooling towers is to facilitate the heat exchange process; they remove heat from the water through evaporation and help dissipate this heat into the atmosphere. By performing this crucial role, cooling towers contribute significantly to efficient operations in industries, from reducing downtime due to overheating to enhancing overall system longevity.

Importance and necessity of industrial cooling towers

Industries require efficient cooling systems to maintain the integrity and performance of their machinery. In manufacturing processes, heat build-up can lead to equipment malfunction, reduced output, and ultimately increased operational costs. Cooling towers are engineered to handle immense volumes of heated water, which is essential for maintaining optimal temperatures and preventing overheating in production lines.

By implementing cooling towers, companies can ensure streamlined operations, which supports energy efficiency and cost-saving measures. The initial investment in a cooling tower can lead to significant ROI through reduced energy usage and prolonged lifespan of machinery, which translates to lower maintenance costs over time.

Types of cooling towers

Cooling towers can be categorized based on their design and function. Natural draft cooling towers utilize natural airflow generated by buoyancy, while mechanical draft cooling towers depend on fans to induce air movement. Each type has its unique advantages, depending on the application's specific needs and environmental factors.

Among mechanical draft cooling towers, several configurations exist, including crossflow cooling towers, which feature water entering horizontally across the air flow; counterflow cooling towers, where the air moves upward and water flows downward; as well as induced and forced draft towers, differentiated by how they manage airflow. Each type's effectiveness will vary based on factors such as location, environmental conditions, and specific cooling requirements.

Health and safety concerns

One critical concern regarding cooling towers is the risk of legionnaires' disease, an illness caused by the Legionella bacteria, which can thrive in warm, stagnant water commonly found in poorly maintained cooling systems. This highlights the importance of regular maintenance and oversight to prevent the stagnation of water and microbial growth, which can lead to health risks for building occupants.

To address health and safety issues, industries must adhere to stringent environmental regulations, including installing required monitoring systems and ensuring regular cleaning and disinfection of cooling towers. Best practices for managing refrigerants and water quality should be established, with adherence to local health standards and industry guidelines to prevent outbreaks and ensure workplace safety.

Installation and management of cooling towers

Installing a cooling tower requires careful planning and consideration of site-specific factors, such as local climate, building codes, and specific cooling needs. The pre-installation phase is crucial, with thorough assessments determining the best type of cooling tower for the application. Once installation begins, attention to detail during key steps such as foundation preparation, mechanical assembly, and connection to water circulation systems is critical.

Once installed, operational best practices must be incorporated to maintain efficiency. Regular routine maintenance including cleaning debris, checking water quality, and monitoring performance indicators is essential for long-term functionality. Businesses should be prepared to troubleshoot common issues like sediment build-up, water flow problems, and pump malfunctions which may arise during the lifespan of the system.

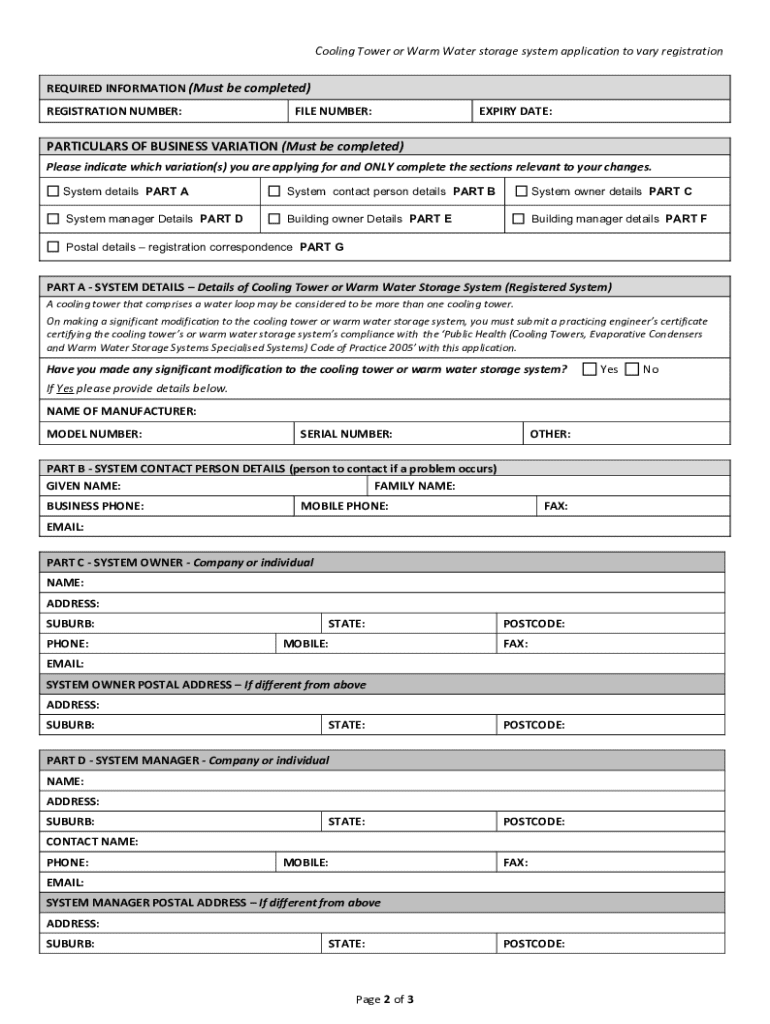

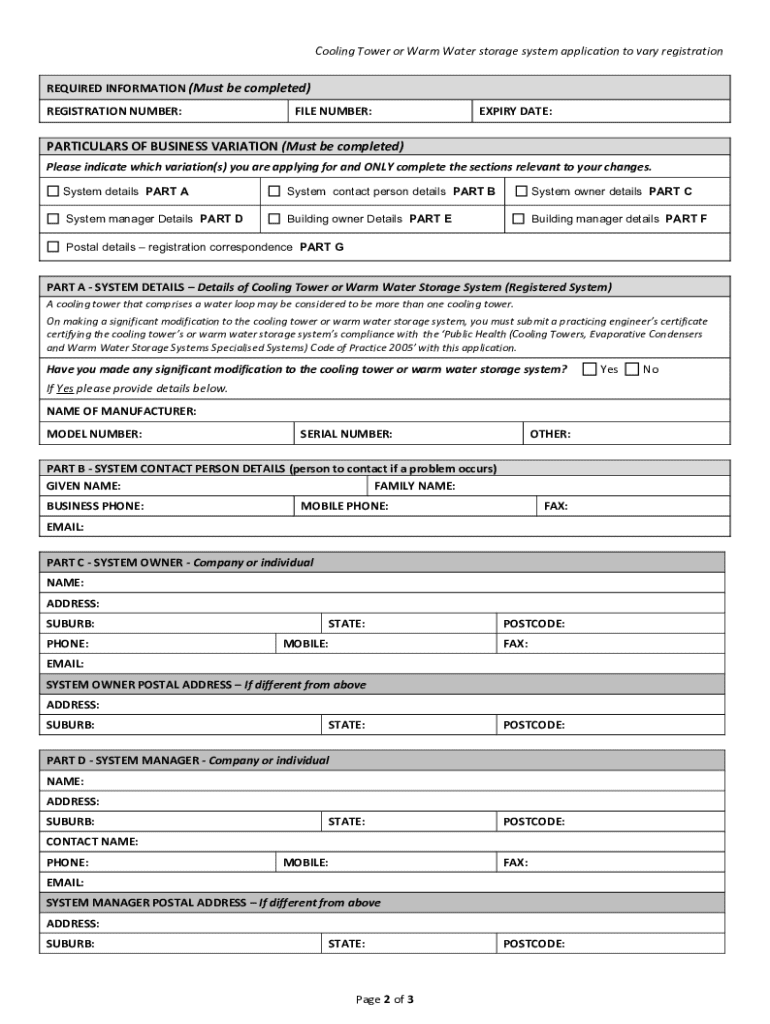

Comprehensive guide to filling out cooling tower forms

Filling out cooling tower forms is a crucial aspect of compliance and operational management. The application process often requires detailed information about the cooling tower's specifications, operational plans, and maintenance schedules. Entities must ensure they meet all local requirements, which can include environmental permitting and health notifications.

When hiring service contractors, it's vital to include essential details such as licensing information and equipment specifications, as well as a detailed service history for past projects. The importance of engaging certified professionals cannot be overstated, as they bring expertise to managing the complexities associated with cooling tower operation and compliance.

Tools and resources for cooling tower management

Digital resources like pdfFiller provide interactive tools that streamline the assessment of cooling tower efficiency. Users can easily access document templates, editing tools, and e-sign capabilities that facilitate the management of compliance documentation associated with cooling towers.

Engaging with relevant case studies gives insight into successful cooling tower implementations, highlighting lessons learned regarding cooling tower efficiency and management practices. Future trends emphasize the integration of smart technology, aiming to optimize cooling and enhance monitoring processes through advanced analytics.

Quick reference

Understanding key terminology in cooling tower management is crucial for efficient operation and compliance. Familiarity with terms like 'thermal efficiency,' 'drift loss,' and 'make-up water' can aid in better communication with contractors and regulatory bodies, ensuring all parties are aligned.

Creating a maintenance schedule template is essential for setting timelines for routine inspections and ensuring optimum performance. Using checklists for each component of the cooling tower also helps to guarantee critical areas are regularly inspected and serviced.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I send cooling tower or warm for eSignature?

How do I edit cooling tower or warm online?

How do I complete cooling tower or warm on an iOS device?

What is cooling tower or warm?

Who is required to file cooling tower or warm?

How to fill out cooling tower or warm?

What is the purpose of cooling tower or warm?

What information must be reported on cooling tower or warm?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.