Get the free Corn Silage Dry Down Data Collection

Get, Create, Make and Sign corn silage dry down

Editing corn silage dry down online

Uncompromising security for your PDF editing and eSignature needs

How to fill out corn silage dry down

How to fill out corn silage dry down

Who needs corn silage dry down?

Corn Silage Dry Down Form: A Comprehensive Guide

Understanding corn silage dry down

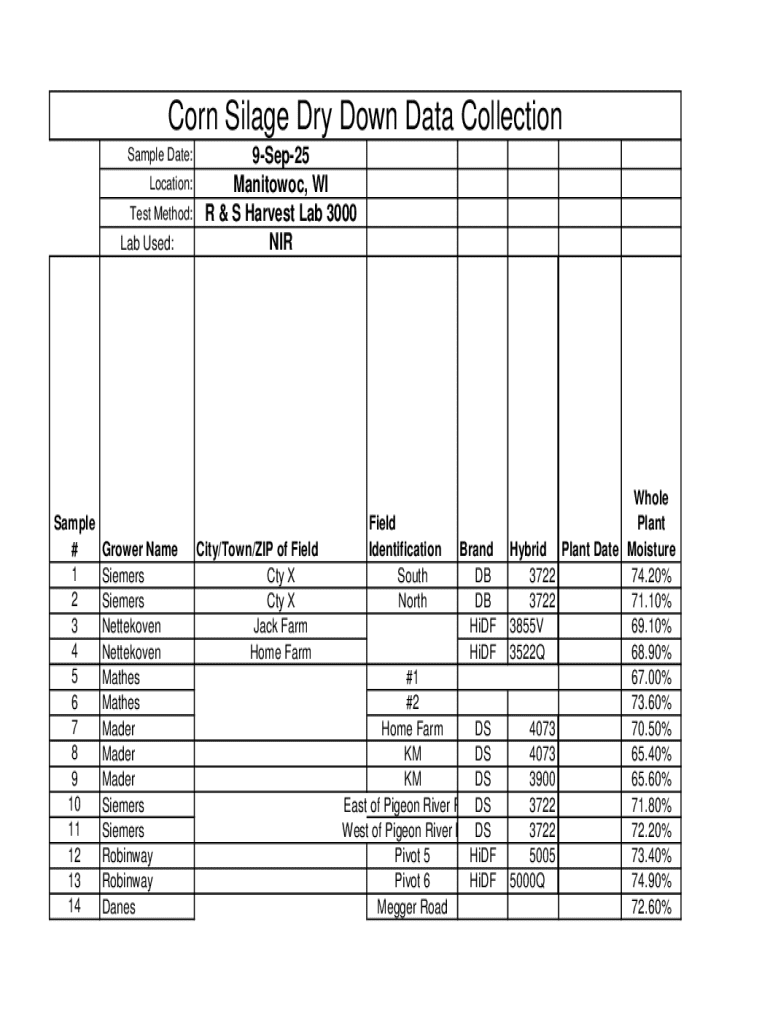

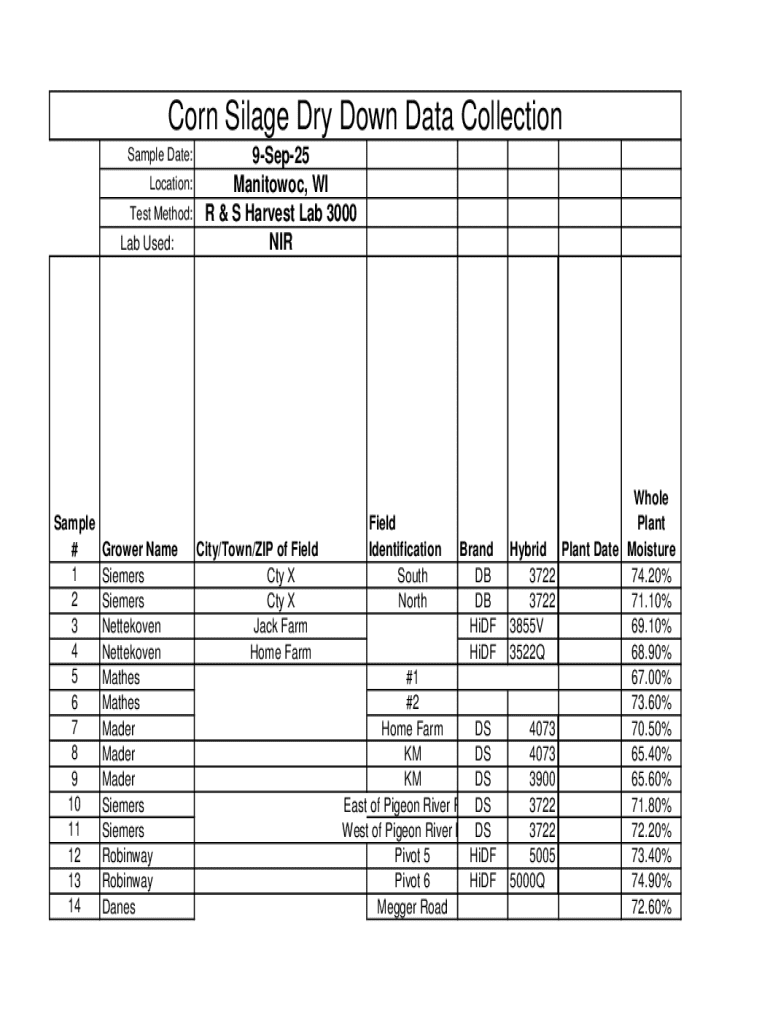

Corn silage dry down is a critical phase in the production of high-quality silage. It refers to the gradual reduction of moisture content in corn plants after they reach physiological maturity but before they are harvested for silage. Proper management of this phase plays a pivotal role in ensuring the nutritional value and overall quality of the silage, directly affecting livestock performance. Understanding corn silage dry down involves knowing how to measure and monitor the moisture levels effectively, which can influence fermentation and preservation during storage.

When the dry down process is managed correctly, it can enhance the fermentability of the silage, leading to improved feed digestibility for cattle. For optimal growth, corn plants undergo physiological changes that dictate the ideal moisture content for harvest. Thus, observing how corn silage fields transition during this phase is key to producing a superior forage crop.

Stages of corn silage dry down

The corn silage dry down process can be effectively monitored week by week, with various key indicators that signal readiness for harvest. Typically, the week-by-week breakdown includes points such as stalk hardness, kernel milk line movement, and kernel moisture content. Farmers should utilize a combination of visual signs and physical properties to gauge the progress of their crop during dry down.

Optimal timing for harvesting corn silage

Identifying the right time for harvesting corn silage hinges on specific indicators and environmental conditions. Factors such as weather conditions, moisture levels, and plant health significantly influence the harvest window. Particularly in states with variable climates, being attentive to fluctuating temperatures and humidity can optimize silage quality. A critical aspect to monitor is kernel firmness and moisture content, which indicate when the forage harvester is ready to make its move.

Generally, the recommended moisture level for corn silage storage lies between 65% and 70%. When corn silage fields reach this moisture content, fermentation processes are enhanced, leading to better preservation and reduced spoilage during storage. Effective management during harvesting ensures high-quality silage production, with both nutritional and economic benefits for farmers.

Factors influencing the corn silage dry down process

Various external factors can significantly affect how and when corn silage dry down occurs. Weather conditions, including temperature and humidity, directly influence the moisture loss from corn plants. Elevated temperatures coupled with low humidity can expedite the drying process, while cool, damp conditions may slow it down, potentially pushing back the harvest date. In regions prone to drought, monitoring moisture topsoil is imperative, as drought can lead to stunted growth and uneven dry down.

Additionally, varietal differences in corn crops also play a crucial role in the dry down timeline. Some hybrids are bred specifically for silage production, boasting favorable characteristics that promote quicker moisture loss, while others may delay this process. It is essential for farmers to select the right varieties tailored to their local conditions and goals to optimize forage quality and harvesting timing effectively.

Best practices for harvesting corn silage

Preparation for harvesting corn silage begins long before the actual event. Steps should include a thorough equipment setup and necessary calibration, ensuring that the forage harvester is functioning optimally. Prior to harvest, conducting a pre-harvest field assessment is vital to ensure uniformity across the field, which can improve the overall efficiency of the harvesting process.

By adopting these best practices, corn silage producers can maximize yields while minimizing losses. Effective harvest techniques lead to better quality silage, which supports livestock health and profitability.

Post-harvest management of corn silage

Immediate actions following the harvest of corn silage can dramatically influence the final product's quality. Prompt processing is essential to lock in the nutritional value and prevent spoilage. It is critical to minimize the period between harvesting and storing, as delays can lead to undesirable fermentation and lower quality silage.

Additionally, various storage techniques, such as bunker silos or bags, can have differing impacts on the finished product. Monitoring temperature and moisture during storage is crucial to maintain silage quality and prevent spoilage.

Tools and resources for managing corn silage dry down

Managing corn silage dry down effectively also involves utilizing modern tools and resources. One standout resource is pdfFiller, which enhances document management for farmers. With pdfFiller, users can fill out harvest forms seamlessly, allowing for accurate record-keeping throughout the corn silage production process.

Utilizing pdfFiller for document management not only streamlines process communication but also enhances collaboration, ensuring that all team members are on the same page throughout the harvest cycle.

Troubleshooting common issues during dry down

Despite careful planning, issues such as delayed dry down or unexpected changes in quality can occur. It is essential to identify and address these problems quickly to minimize their impact on silage quality. For instance, if kernels are not drying down at the expected rate, factors such as excess moisture from rainfall or disease could be at play. Farmers can use tools like moisture meters to assess field conditions actively.

Additionally, consulting with local agricultural extension services or experts can provide vital guidance and support to resolve any complications encountered throughout the dry down process.

Personalizing your corn silage experience

To further personalize the corn silage management experience, farmers can take advantage of the customization options available in pdfFiller. Tailoring document solutions to specific needs enhances efficiency and helps farmers stay compliant with local regulations and best practices.

Integrating real-time data and local practices ensures that each farm can maximize their silage's quality, contributing to overall productivity.

Future considerations in corn silage management

As practices and technologies continue to evolve, staying informed about emerging trends in corn silage management is crucial. Technological advancements, including precision agriculture tools and genetic improvements in corn hybrids, are reshaping how farmers approach silage production. Integrating these advancements can lead to better moisture management and improved fermentation protocols.

By embracing innovative practices while maintaining an eye on sustainability, farmers can refine their dry down strategies, ensuring high-quality corn silage that supports livestock health and productivity for years to come.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Can I create an eSignature for the corn silage dry down in Gmail?

How do I fill out the corn silage dry down form on my smartphone?

How do I complete corn silage dry down on an iOS device?

What is corn silage dry down?

Who is required to file corn silage dry down?

How to fill out corn silage dry down?

What is the purpose of corn silage dry down?

What information must be reported on corn silage dry down?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.