Get the free Effectiveness of Shrink-wrap Packaging on Extending the Shelf-life ...

Get, Create, Make and Sign effectiveness of shrink-wrap packaging

How to edit effectiveness of shrink-wrap packaging online

Uncompromising security for your PDF editing and eSignature needs

How to fill out effectiveness of shrink-wrap packaging

How to fill out effectiveness of shrink-wrap packaging

Who needs effectiveness of shrink-wrap packaging?

Effectiveness of shrink-wrap packaging form

Understanding shrink-wrap packaging

Shrink-wrap packaging is a highly efficient method for encasing products in a thin layer of plastic film, which is then heated to conform tightly around the items. This packaging solution is widely utilized across various sectors due to its protective qualities and aesthetic appeal. The shrink-wrap process involves wrapping the desired product in a sheet of polyethylene or other advanced materials, followed by the application of heat which causes the film to shrink and create a snug fit around the product.

Industries that benefit from shrink-wrap include e-commerce, food and beverage, pharmaceuticals, and consumer goods. It is especially useful for bundling and safeguarding multiple items, such as bottles, cans, or boxes, thus streamlining logistics and preserving product integrity during transportation and storage.

Why shrink-wrap packaging is a game changer

Shrink-wrap packaging stands out primarily for its ability to provide high levels of protection. The physical properties of the shrink film create a barrier against dust, moisture, and contaminants. Case studies reveal that companies employing shrink-wrap experienced a significant reduction in product damage compared to those using standard packaging methods. For example, a major food retailer that switched to shrink-wrap for its frozen products noted a 40% decrease in spoilage rates.

Additionally, shrink-wrap’s durability ensures that it withstands environmental stressors much better than traditional packaging options. The moisture and UV resistance of shrink-wrap translate to longer shelf lives for products, ultimately benefiting both the seller and the consumer.

The unique benefits of shrink-wrap packaging

An often-overlooked advantage of shrink-wrap packaging is its enhanced visual appeal. The clear, glossy finish of shrink-wrapped products greatly elevates their presentation, making them more attractive to consumers. This aesthetic improvement can drive sales, as visually appealing products tend to attract more attention on retail shelves, providing a substantial marketing advantage.

Moreover, shrink-wrap packaging can be more cost-effective in the long run. When comparing initial costs, shrink-wrap can appear competitive, but the real savings emerge through reduced damage rates, lower replacement costs, and diminished storage needs due to the compact nature of bundled products. Over time, businesses can save significantly on materials and logistical expenses, making shrink-wrap a wise investment.

Considerations when choosing shrink-wrap packaging

When selecting shrink-wrap packaging for your products, ensure product compatibility is a primary consideration. Not all items benefit equally from shrink-wrap. For delicate products such as electronics or fragile glass, determining the best shrink material and thickness is vital to avoid damage. Conducting test runs can also assist in assessing how your items hold up during the wrapping process.

Cost analysis is another crucial factor; while shrink-wrap equipment may require initial investment, evaluating potential savings in overall costs—including damaged goods and storage inefficiencies—is essential for budgeting. Always account for cost considerations when selecting the right shrink-wrap machinery and materials for your operations.

Practical steps for implementing shrink-wrap packaging

Implementing shrink-wrap packaging in your business involves several practical steps. First, selecting the right equipment is critical; equipment choices range from handheld sealers to high-speed automatic wrappers. Key factors such as the speed of operation, volume of production, and product size must align with your business’s needs.

Secondly, choosing appropriate materials is vital. Many options are available, from polyethylene to polyolefin films, each with distinct properties affecting shrink performance, visual appeal, and environmental impacts. Finally, training your team effectively ensures that the operation runs smoothly and maintains quality control, ensuring every package meets expectations for both protection and aesthetics.

Real-world success stories

The effectiveness of shrink-wrap packaging is evidenced through numerous real-world success stories. For instance, an e-commerce giant revamped its logistics process by integrating shrink-wrap solutions, drastically reducing shipping costs and enhancing delivery efficiency. The company reported quicker turnaround times and improved customer satisfaction due to better product condition upon arrival.

In the food industry, a notable innovator began using shrink-wrap to extend the shelf life of its premade meals, achieving reduced food waste and maximizing product freshness. Lastly, a manufacturing company in pharmaceuticals reported a 30% cost reduction due to the advent of shrink-wrap packaging, which streamlined operations and minimized waste throughout the production cycle.

Interactive tools and resources

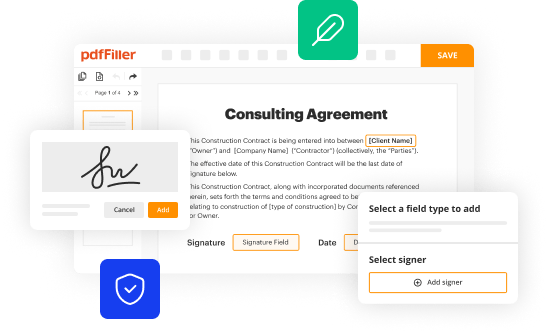

For teams looking to implement shrink-wrap packaging effectively, pdfFiller offers invaluable resources. Utilizing pdfFiller for document management allows for seamless organization of packaging documentation, facilitating easy access and modifications from anywhere. Users can create interactive forms for tracking shrink-wrap inventory, ensuring efficient management of material usage.

Additionally, pdfFiller provides templates ideal for cost-benefit analyses, helping users to calculate the return on investment for transitioning to shrink-wrap. Moreover, guides for compliance and safety documentation ensure that all packaging meets required regulatory assessments, creating a smoother path to success in shrink-wrap implementation.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I get effectiveness of shrink-wrap packaging?

How do I edit effectiveness of shrink-wrap packaging online?

Can I sign the effectiveness of shrink-wrap packaging electronically in Chrome?

What is effectiveness of shrink-wrap packaging?

Who is required to file effectiveness of shrink-wrap packaging?

How to fill out effectiveness of shrink-wrap packaging?

What is the purpose of effectiveness of shrink-wrap packaging?

What information must be reported on effectiveness of shrink-wrap packaging?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.