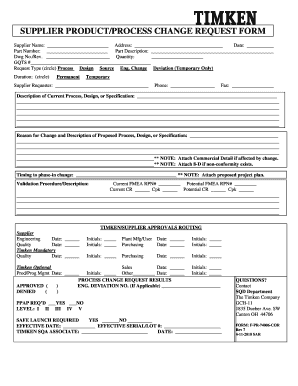

Fmea Procedure

What is fmea procedure?

FMEA, which stands for Failure Mode and Effects Analysis, is a systematic method used to identify potential problems or failures in a design, process, or system, and to prioritize them based on severity, occurrence, and detection. By analyzing potential failure modes and their effects, FMEA helps to prevent or mitigate risks and improve reliability.

What are the types of fmea procedure?

There are three main types of FMEA procedures: 1. Design FMEA (DFMEA): It focuses on potential failures in the design of a product or system before it is manufactured. DFMEA helps to identify and eliminate design weaknesses that could lead to failures or safety issues. 2. Process FMEA (PFMEA): It analyzes potential failures in the manufacturing or assembly process. PFMEA aims to identify and address process-related risks that could affect quality, efficiency, or safety. 3. System FMEA (SFMEA): It examines potential failures or risks at the system level, considering how different components or subsystems interact. SFMEA helps to ensure the reliability and functionality of complex systems.

How to complete fmea procedure

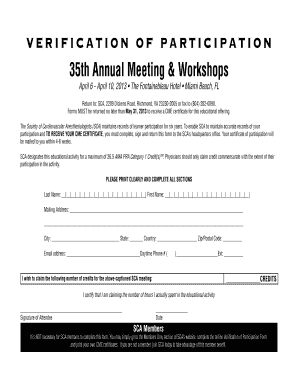

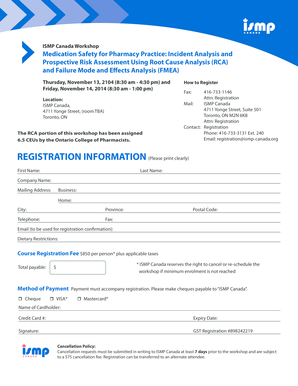

Completing an FMEA procedure involves the following steps: 1. Identify the scope: Define the specific design, process, or system that will be analyzed. 2. Assemble a team: Form a multidisciplinary team with knowledge and expertise in the relevant areas. 3. Breakdown the process: Divide the design, process, or system into manageable steps or components. 4. Identify potential failure modes: Brainstorm and list all possible ways in which each step or component could fail. 5. Evaluate severity: Assess the potential severity of each failure mode on a predefined scale. 6. Determine occurrence: Evaluate the likelihood or frequency of each failure mode occurring. 7. Assess detection: Determine the ability to detect each failure mode before it reaches the end user or customer. 8. Calculate the risk priority number (RPN): Multiply severity, occurrence, and detection scores to prioritize failure modes. 9. Develop mitigation strategies: Identify and implement actions to reduce or eliminate high-risk failure modes. 10. Monitor and review: Continuously monitor the effectiveness of mitigation measures and update the FMEA as necessary.

pdfFiller is a powerful online platform that empowers users to easily create, edit, and share documents online. With unlimited fillable templates and a comprehensive set of editing tools, pdfFiller is the go-to PDF editor for individuals and businesses alike. Whether you need to fill out forms, collaborate on documents, or make changes to PDF files, pdfFiller has you covered. Its user-friendly interface and robust features make it the only PDF editor you'll ever need to get your documents done efficiently and professionally.