Equipment Maintenance Log Pdf

What is Equipment maintenance log pdf?

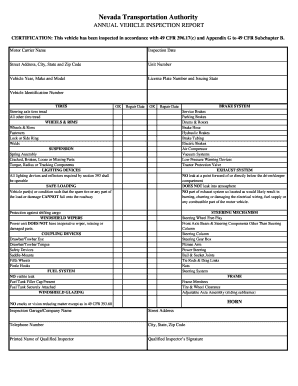

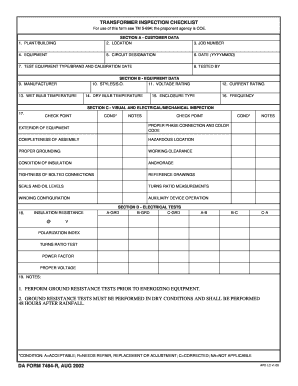

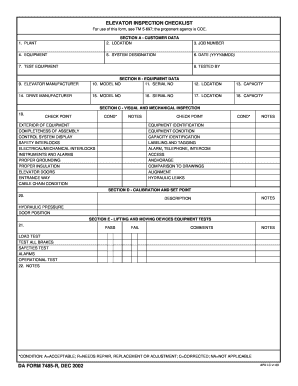

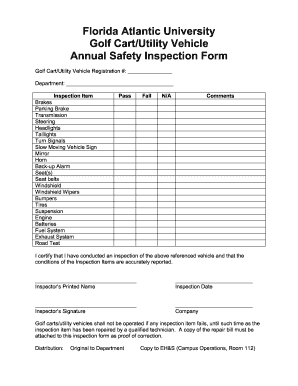

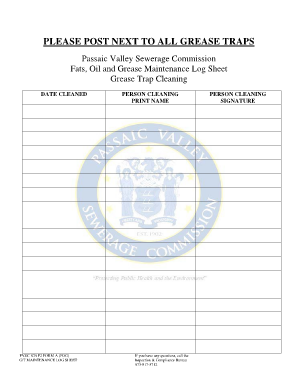

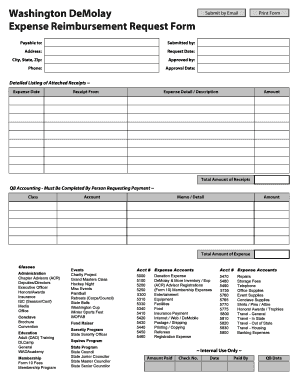

An Equipment maintenance log pdf is a digital document used to track and record the maintenance activities performed on equipment. It helps businesses keep a detailed history of maintenance procedures, ensuring equipment is well-maintained and running efficiently.

What are the types of Equipment maintenance log pdf?

There are several types of Equipment maintenance log pdf that cater to different industries and equipment types. Some common types include:

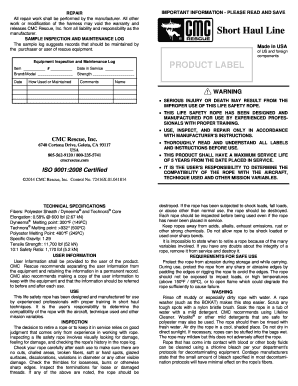

Basic Equipment maintenance log pdf for general equipment maintenance

Advanced Equipment maintenance log pdf for specialized equipment maintenance

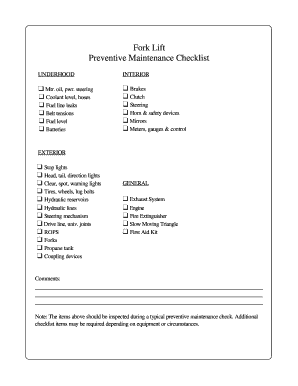

Preventive maintenance log pdf for scheduling routine maintenance tasks

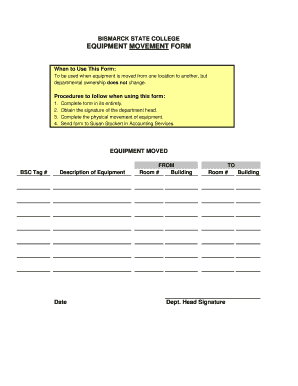

How to complete Equipment maintenance log pdf

Completing an Equipment maintenance log pdf is a straightforward process that involves the following steps:

01

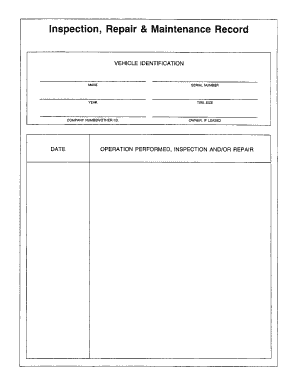

Fill in the equipment details such as name, model, and serial number.

02

Record the date and type of maintenance performed.

03

Describe the maintenance procedure and any parts replaced or repaired.

04

Include the technician's name and signature.

05

Review and save the completed log for future reference.

pdfFiller empowers users to create, edit, and share documents online. Offering unlimited fillable templates and powerful editing tools, pdfFiller is the only PDF editor users need to get their documents done.

Video Tutorial How to Fill Out Equipment maintenance log pdf

Thousands of positive reviews can’t be wrong

Read more or give pdfFiller a try to experience the benefits for yourself

Questions & answers

What is the equipment maintenance record?

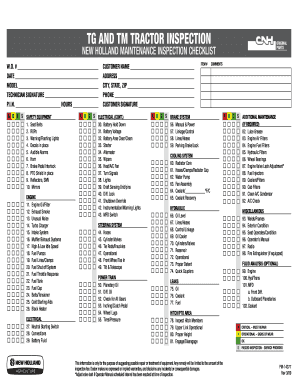

An equipment maintenance log is a document that records activities that have been performed on an asset. It takes at least a handful of key equipment to keep a plant operational. It is unimaginable how much time and effort goes into maintenance activities for each asset annually.

How do you fill out a equipment maintenance log?

Creating an equipment maintenance log is easy once you add the following details: Facility location. Asset name and serial number. Equipment manufacturer name and contact. Asset maintenance technician and operator's name. Date of asset purchase, first use, and maintenance. Description of asset maintenance activities.

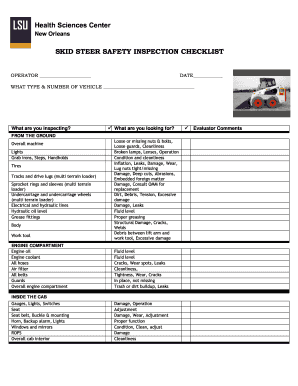

Why is the equipment log book important?

Why is the equipment maintenance log important? It increases resale value of equipment. Proper maintenance and tracking of the equipment maintenance log help your equipment to run in optimal condition. It identifies trends across makes, models, or components. It increases the safety of operators.

How do I make a maintenance log?

How to Create an Equipment Maintenance Log Name of the asset. Serial number. Equipment manufacturer and its contact details. Date of purchase. Date of first use. Operator responsible for the asset. Location of facility. Date of maintenance.

Why is a maintenance log book important?

Maintenance record keeps information regarding reach maintenance and repair done on equipment. With help of maintenance record, one can easily determine when and which maintenance strategy is required to be performed on particular asset. These helps to prevent assets from failure and reduces cost required to repair.

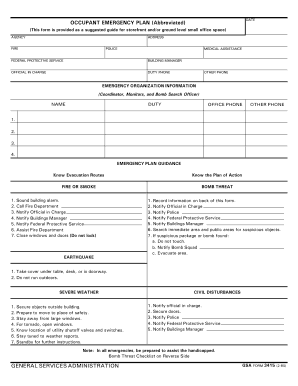

What does a maintenance log include?

This log typically includes details such as the date and time of maintenance, the specific activities carried out, the personnel involved, any parts or materials used, and any observations or issues identified during the maintenance process.