Fmea Analysis Pdf

What is fmea analysis pdf?

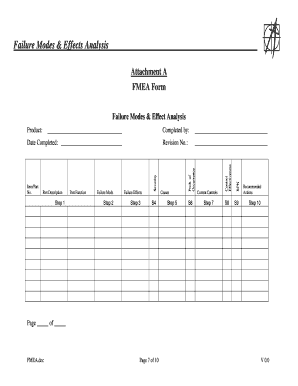

FMEA (Failure Mode and Effects Analysis) is a systematic approach used to identify and evaluate potential failures and their effects on processes, products, or services. FMEA analysis pdf refers to the use of a PDF format for conducting and documenting FMEA analysis. By utilizing a PDF format, it becomes easier to create, share, and store FMEA analysis documents in a consistent and organized manner.

What are the types of fmea analysis pdf?

There are three main types of FMEA analysis pdf: System FMEA, Design FMEA, and Process FMEA. 1. System FMEA: This type of analysis focuses on failures and their effects at the system level. 2. Design FMEA: Design FMEA aims to identify and mitigate potential failures in the design phase of a product or system. 3. Process FMEA: Process FMEA analyzes failures and their effects within a specific manufacturing or production process.

How to complete fmea analysis pdf

Completing FMEA analysis in PDF format involves the following steps: 1. Identify the scope and purpose of the analysis. 2. Assemble a cross-functional team of experts. 3. Identify potential failure modes and their effects. 4. Assess the severity, occurrence, and detection of each failure mode. 5. Calculate the Risk Priority Number (RPN) for each failure mode. 6. Prioritize the failure modes based on their RPN. 7. Develop and implement mitigation actions. 8. Continuously monitor and review the effectiveness of the mitigation actions.

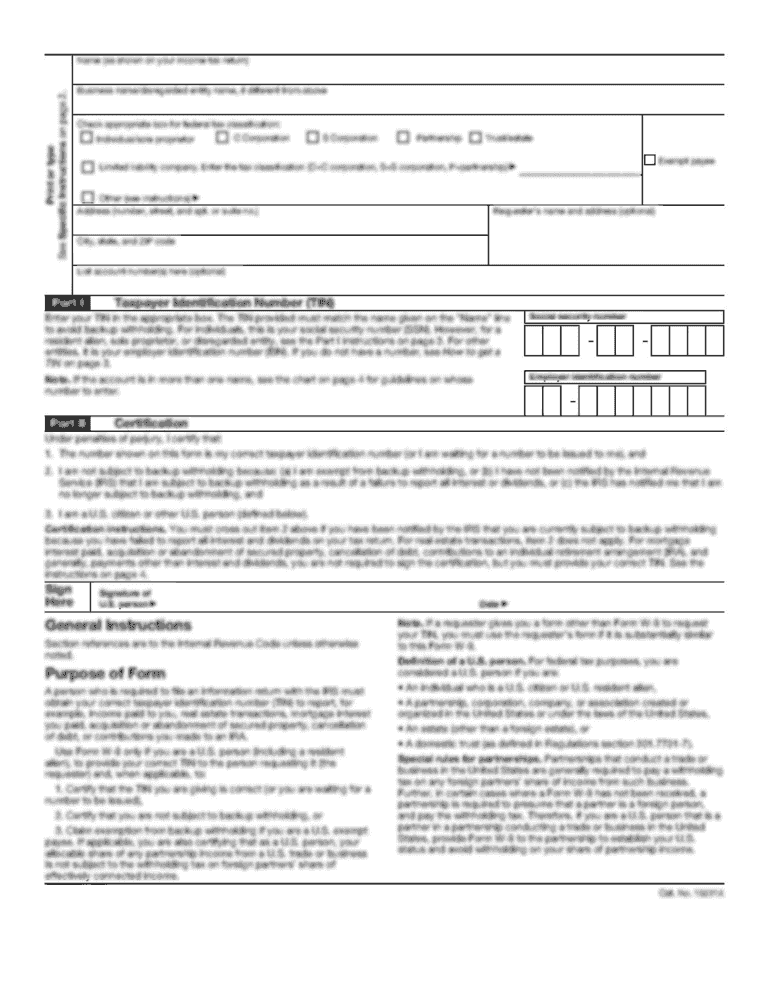

pdfFiller empowers users to create, edit, and share documents online. Offering unlimited fillable templates and powerful editing tools, pdfFiller is the only PDF editor users need to get their documents done.