Who needs a Form N1?

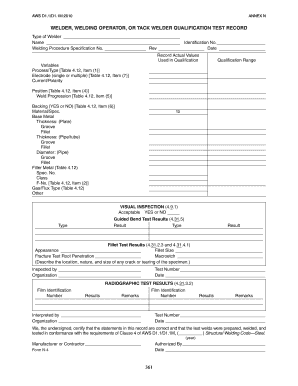

Form N1 is designed by the AWS Structural Welding Committee and approved for use as a legal document for recording the welding procedure specifications or procedure qualification records.

What is AWS Form N-1 for?

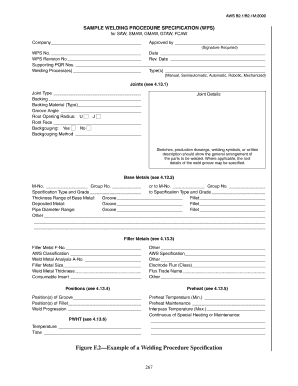

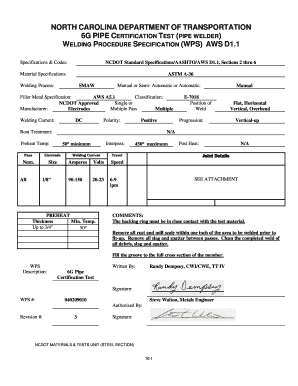

This Welding Procedure Specification certifies that the test welds were prepared, welded, and tested in conformance with the requirements of Clause 4 of AWS D1.1/D1.1M, Structural Welding Code — Steel. This form, Welding Procedure Specification (WPS), is meant to be used for the recording of WPS qualifications, welder qualification, welding operator qualification, and tack welder qualification data required by the AWS D1.1 code.

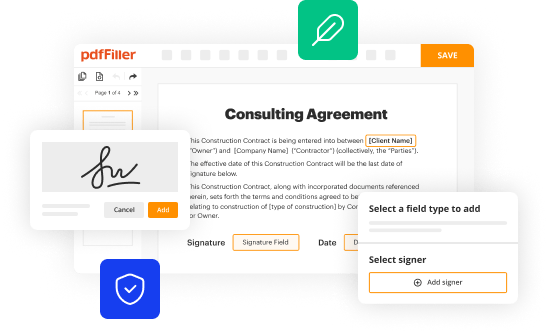

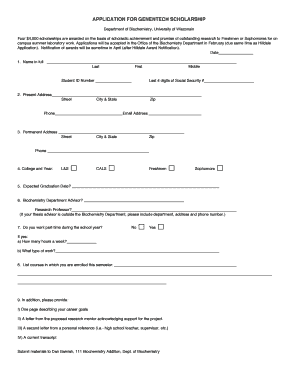

How do I fill out Form N1?

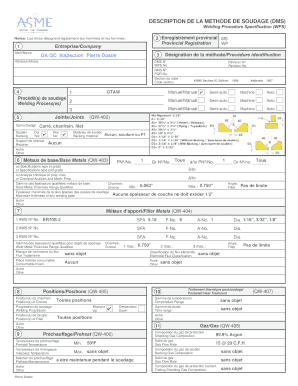

This AWS WPS form consists of two main parts. The first is the main part, which should provide the following information:

-

Company name, Welding Process;

-

Supporting PQR No.

-

Information on the joined designed used;

-

Information on the base metals used;

-

Information on the electrical characteristics;

-

Information on the filler metals used;

-

Information describing shielding;

-

Information on technique which is used;

-

Indication of the postweld heat treatment;

The last block of the first part of the form is Welding Procedure. The technical details on how the welding procedure was prepared must be indicated here.

The second part of the form is the Procedure Qualification Records (Test Results). Results of the Tensile Test and the Guided Bend Tests are to be provided in the appropriate tables of this part of the AWS Form PQR.

Also, results of the visual inspection and radiographic-ultrasonic examination are to be recorded in this part of the form.

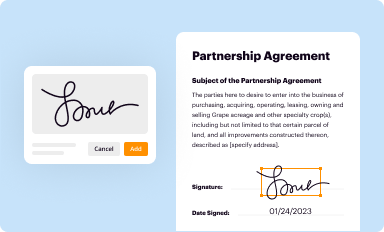

Once completed, the form must be signed and dated.

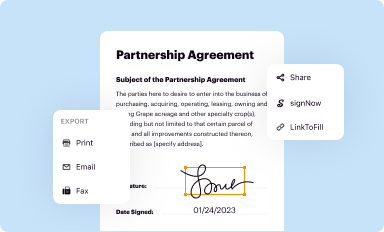

Where do I send Form N1?

Once completed and signed, the welding procedure forms may be directed to any party to whom this information may concert or who is requesting this information.