Get the free lift plan template

Fill out, sign, and share forms from a single PDF platform

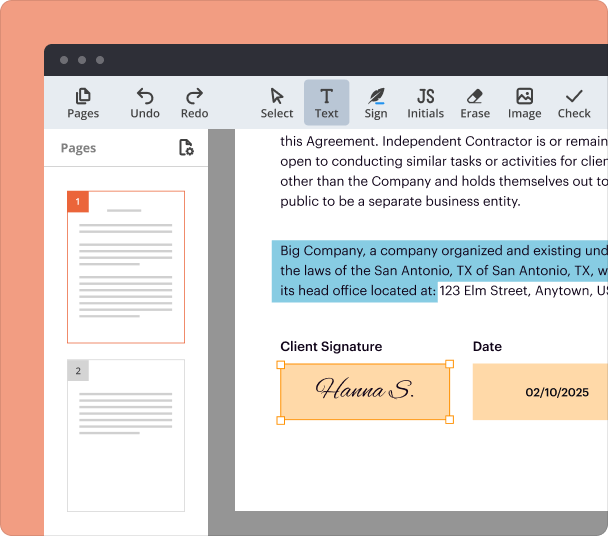

Edit and sign in one place

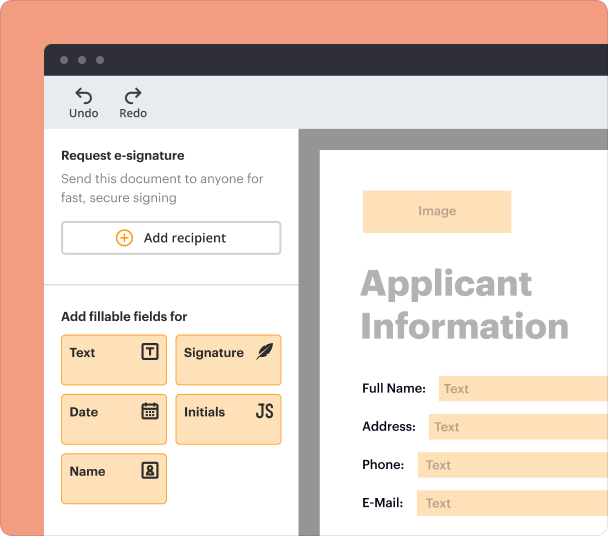

Create professional forms

Simplify data collection

Manage forms centrally

Why pdfFiller is the best tool for your documents and forms

End-to-end document management

Accessible from anywhere

Secure and compliant

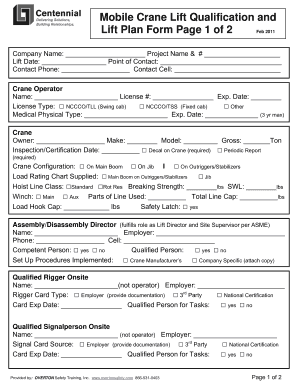

Long-Read How-to Guide on Basic Lift Plan Template Form

How to fill out a basic lift plan template form

Filling out a basic lift plan template form involves understanding the specific requirements of your lifting operation, including assessing risks and ensuring compliance with safety regulations. This guide will provide step-by-step instructions on how to complete the form accurately and efficiently, allowing for safe and effective lifting operations.

What is a basic lift plan template?

A basic lift plan template serves as a foundational document that outlines the procedures and requirements for lifting operations. Its importance lies in standardizing the approach to lifting tasks while ensuring safety and compliance with industry regulations.

-

A lift plan details how a lift will be conducted, showcasing all necessary precautions, which helps to mitigate risk during operations.

-

Essential elements include the type of load, equipment used, and the method of lifting to strategize effectively.

-

Tailoring a lift plan to specific operations ensures that all potential hazards are accounted for and addressed.

How can lifting operations be identified?

Identifying lifting operations begins with clearly outlining the actual scope of work involved in the project. Recognizing what tasks require lifts helps in formulating effective lift plans.

-

A well-defined scope enables planners to allocate resources effectively and anticipate potential challenges.

-

Key details include the load's weight and shape, the lifting mechanism, and site conditions.

-

The appointed person must ensure adherence to safety norms and oversee the lift execution.

What steps are involved in filling out the basic lift plan template?

Completing a basic lift plan template requires systematic steps to legally and effectively outline operations. Following these steps ensures safety and compliance throughout the lifting process.

-

Follow the provided fields closely, ensuring accurate input of all relevant information.

-

Critical fields include load characteristics and equipment specifications, which must be detailed correctly.

-

Refer to local regulations (e.g., OSHA guidelines) as you fill out the template to ensure compliance.

What are key safety control measures for lifting?

Safety control measures are vital in preventing incidents during lifting operations. Understanding the specific risks and implementing suitable control measures is critical for all lifting activities.

-

Implement measures such as outriggers and counterweights to stabilize cranes during lifts.

-

Utilize safety equipment like harnesses and barriers to mitigate risks of falling loads.

-

Regularly conduct risk assessments to identify and prioritize safety measures needed before commencing lifts.

How to understand crane details in the lift plan?

Understanding crane specifications is essential in the successful execution of any lift plan. Different cranes have various capabilities and limitations that must be considered.

-

Familiarize yourself with various crane types such as tower, mobile, and rough-terrain cranes and their specific purposes.

-

Each crane has specific load capacities; understanding jib configurations enhances lift versatility.

-

Use crane specifications in your lift plan to address risks associated with equipment limitations.

What benefits does pdfFiller provide for managing your lift plan?

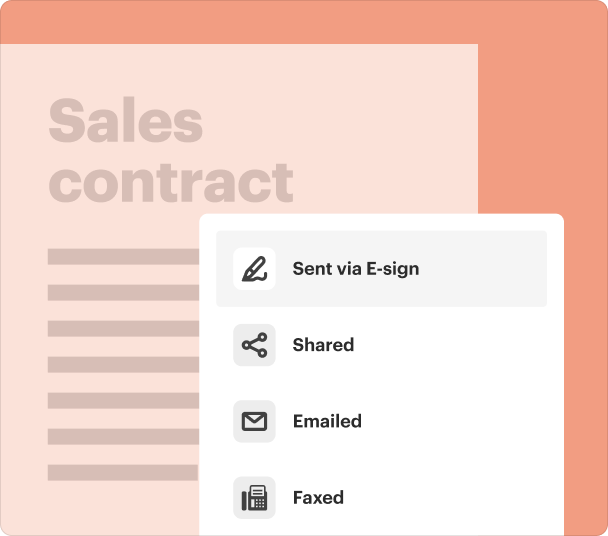

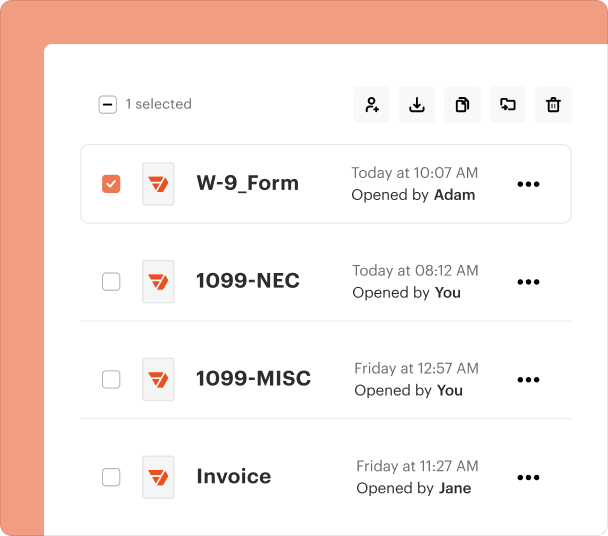

pdfFiller offers a comprehensive management solution for your lift plan documents. Its features allow you to edit, sign, and share plans effortlessly.

-

Elevate your document workflows with a single platform that integrates multiple functionalities like editing and signing.

-

Collaborate effectively with team members, utilize e-signatures for prompt approval, and ensure accountability.

-

With cloud-based technology, retrieve your lift plan any time, crucial for on-site adjustments.

What are the legal compliances for construction site regulations?

Compliance with legal regulations is essential for all construction activities, including lifting. Understanding local guidelines helps you to avoid legal complications.

-

Familiarize yourself with local laws that dictate procedural demands for lift operations.

-

OSHA provides regulations and best practices that must be adhered to for safe and compliant lifting.

-

Engage with local authorities to ensure your lift plan aligns with approved regulatory standards.

How to finalize your lift plan template?

Finalizing the lift plan involves a thorough review process to ensure all information is complete and accurate. Proper management practices will safeguard against operational risks.

-

Involve all necessary stakeholders in the review to confirm that all aspects of the lift plan are covered.

-

Opt for cloud storage solutions for easy access and secure backup of important documents.

-

Facilitate smooth sharing of the finalized lift plan among team members to enhance collaborative operations.

Frequently Asked Questions about lifting plan template form

What is a basic lift plan?

A basic lift plan is a document outlining the procedures and requirements necessary for lifting operations, ensuring safeness and compliance with regulations.

How do I know if my lift plan is compliant?

Review local regulations and guidelines, such as OSHA rules, to ensure compliance. Consultation with regulatory bodies can provide additional assurance.

Can I edit my lift plan after completion?

Yes, you can edit your lift plan using tools like pdfFiller to modify and update the document as needed for ongoing projects.

What measures can I take to ensure crane safety?

Implement appropriate control measures, conduct risk assessments, and adhere to the lift plan's guidelines to ensure crane safety.

What are the penalties for not complying with lift plan regulations?

Non-compliance can result in fines, project delays, and increased liability in case of accidents. It's crucial to maintain adherence to all safety regulations.

pdfFiller scores top ratings on review platforms