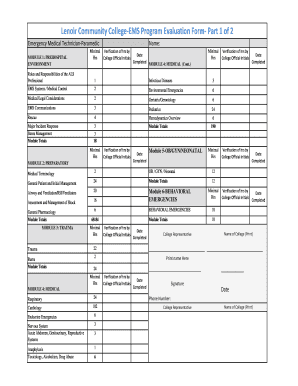

Brink Constructors Annual Fall Protection Equipment free printable template

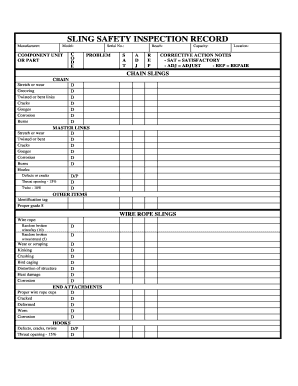

Get, Create, Make and Sign fall inspection checklist form

How to edit safety harness inspection sheet online

Uncompromising security for your PDF editing and eSignature needs

How to fill out safety harness checklist pdf form

How to fill out Brink Constructors Annual Fall Protection Equipment Inspection

Who needs Brink Constructors Annual Fall Protection Equipment Inspection?

Video instructions and help with filling out and completing annual fall protection inspection form

Instructions and Help about annual fall inspection

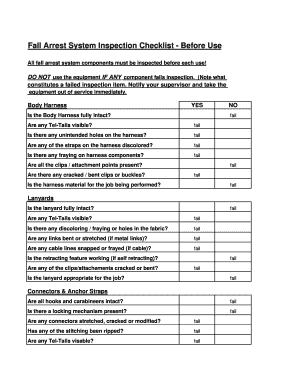

Today were going to discuss how to inspect and how to properly Don your full body harness before you use any part of a personal fall arrest system you're required to inspect it if you find anything wrong with the equipment if it does not pass the inspection you must take it out of service before you start the inspection you want to grab the harness by the back dorsal d-ring raise it up and shake it what this will do is allow the leg straps to fall downward where they need to be if it's a little jumbled up giving it a shake will smooth out the harness, so it can hang correctly the first things you want to look at are the impact indicators on a harness there are two of them you can see that its just webbing fold it over, and it says impact indicator if the impact indicator is neither there nor has been exposed stop the inspection and remove the harness from service next you'll want to inspect the labels if you cannot read the labels you cannot use that harness it must be taken out of service when inspecting hardware well start from the top and work our way down first look at the back dorsal d-ring make sure there's no major bins cracks or discoloration next check your chest strap make sure that the Quick Connect or mating buckle is able to close and stay closed if it's a quick connect it needs to be able to lock into itself and the green dot will tell you that it has in fact locked you want to make sure that it cannot come loose for the mating buckle you pass the buckle through the slot and give it a couple of short pulls to make sure it will stay in place as well the next thing you'll be inspecting are your adjusters mating buckle adjusters or rolling friction buckle adjusters on the roller keep in mind that any piece of hardware that has a spring or roller the roller has to roll in the spring has to function with the mating buckle adjusters make sure that the webbing freely passes through, and it can lock down now lets look at the leg straps there are three types of leg buckles for harnesses tongue and buckle mating buckle and the Quick Connect if it's a tongue and buckle look at the grommets look for cracked bent or missing grommets you also want to make sure that the tongue and buckle sets neatly by itself and against the gate, so it doesn't move against the bar look at it if the bar has rotation, and you are able to spin it you need to make sure it can spin, and it's not bent if it's a quick-connect you just like with the chest strap we reviewed earlier it needs to be able to lock into itself so the Green Dot shows, and it has been locked again for the mating buckle you pass the buckle through the slot and give it a couple short pulls to make sure it will stay in place ok lets talk about webbing you always want to do this inspection without your gloves on first an easy one is tears holes or discoloration of the webbing grass the webbing with your hands and bend it in an inverted u fashion checking both sides this creates surface tension...

People Also Ask about harness inspection template

What are the minimum requirements for a safety harness?

How do you do a harness inspection?

What four 4 items do you look for when inspecting a lanyard?

What are the OSHA requirements for safety harness inspections?

Can I write on my safety harness?

How often do safety harnesses need to be inspected?

Our user reviews speak for themselves

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I manage my body harness inspection checklist pdf directly from Gmail?

How do I make changes in fall protection checklist template?

How do I make edits in annual fall protection inspection checklist pdf without leaving Chrome?

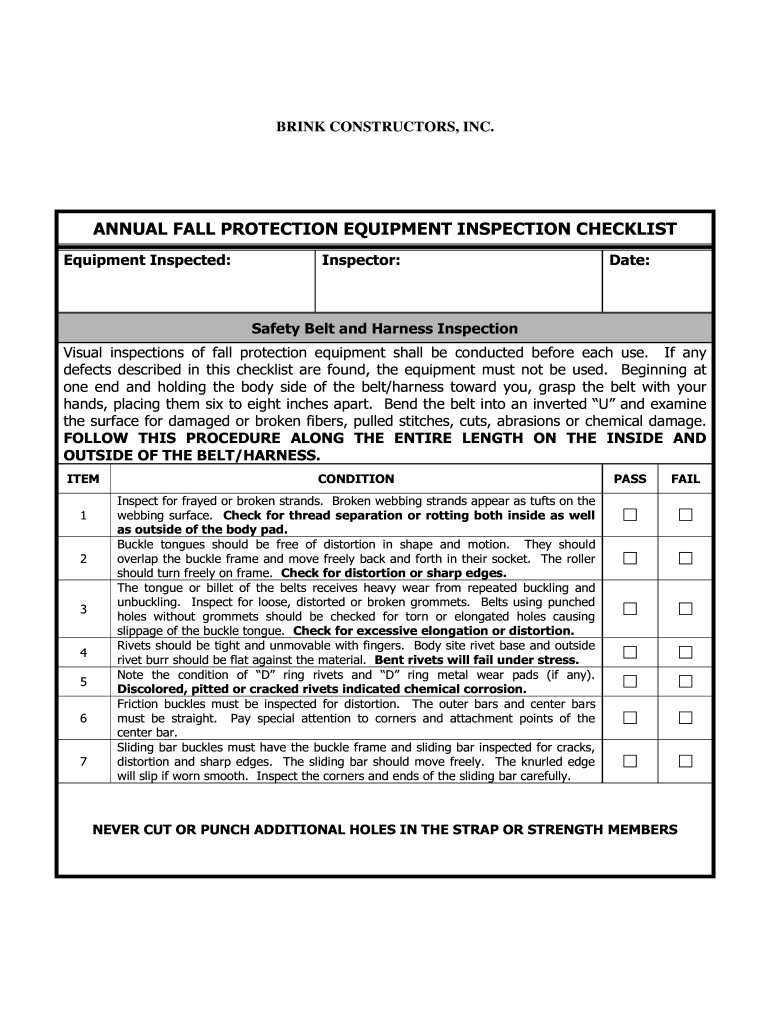

What is Brink Constructors Annual Fall Protection Equipment Inspection?

Who is required to file Brink Constructors Annual Fall Protection Equipment Inspection?

How to fill out Brink Constructors Annual Fall Protection Equipment Inspection?

What is the purpose of Brink Constructors Annual Fall Protection Equipment Inspection?

What information must be reported on Brink Constructors Annual Fall Protection Equipment Inspection?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.