Get the free chiller log sheet excel

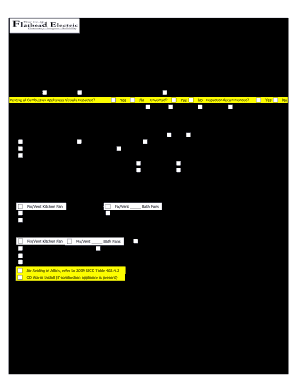

Get, Create, Make and Sign chiller log sheet form

Editing daily chiller log sheet online

Uncompromising security for your PDF editing and eSignature needs

How to fill out chiller reading sheets form

How to fill out a chiller log sheet in Excel:

Who needs a chiller log sheet in Excel?

Video instructions and help with filling out and completing chiller log sheet excel

Instructions and Help about chiller log book

Funny make sure the other one is running before you shut this off is if I shut these pumps off we'll have the entire chiller system down we have no water for the condensers so that one is running so go ahead and shut this one off first thing we're doing so see what we got way to drain it bad boy here made by right tools also speak my like wheeze you alright guys so just a little trick all I do is I keep one of the bolts on so that I can just leave it and just swing it around like, so you can yell delight take a look here you guys see that it's no Dino it's bad let's bring it up to the light, and we take a look this is why you have to pull the trainer see that right there go ahead and clean the last cut out a little giving my drain is clogged I get all that stuff out of there this by hand I'll just shove them for from the floor later alright guys let's take a look at the strainer okay clean the bed go ahead and put our strain of again kind of want to get it straight nice and straight Oh these guys, so no leaks all right, so that's that so being at this one was dirty I'm going to go ahead and just take a peek driving a car some Mustang kid okay careful to us and all still thinks we're drained is not close by I am in the basement Caves know it's tall some locations I have to put so fuck it's all that stuff they came out of the other pump Kasich sees everything we're doing that all coolant our job the gearbox like I said you can't fold some locations you know you need to catch the water to drain main table was close by this is the basement enough I apologize if I offend anybody, but it's not a head job it's just you know I'm in the basement it's not a big deal I mean Johnny so let me take this guy up this was all so dirty I'm going to pull it out clean it put it back in there's not as bad as the other one just a little down here, and I say in most cases if one is clean the other ones also clean because it is the same piping coming in, and so I'm gonna pull this out and clean it put it back in, and I'm going to close up I want to pull this pain is out of this is the condenser water loop the chilled water loop I'm not gonna even touch it closed loop never dirty I want to go ahead open this would you play through that look at this Earl right here number two Earl hey Steve man come and get this Earl out here, so I got my stop off hey one's good I'll just valve this off, and he's down when it's not holding condense the water the tank and this is water coming in there both valve both butterfly valves and then a gene right here little of drain a little water here be right there so the drain all right there see inside see I'm saying better Tunnel it all right guys morning conduit here that I'm gonna used to pull out that last one hopefully Stasis we go clean these and after a lifetime today but what I usually do is I just go through the control boxes make sure the wiring looks good nothing's fine you know make sure that all the folds clear the falls see why...

People Also Ask about carrier chiller maintenance checklist

How many types of PPM are there?

How do you clean a water chiller?

What is PPM in maintenance?

What is chiller ppm?

What is security checking in chiller?

How often should a chiller be serviced?

When should I overhaul my chiller?

How do you maintain a chiller system?

What are the safety controls in chiller?

How long should a chiller last?

What are the 4 main components of a chiller system?

What is PPM HVAC?

Why is chiller maintenance important?

What are the maintenance in chiller system?

How do you inspect a chiller?

What are the chiller parameters?

Our user reviews speak for themselves

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I edit chiller checklist excel in Chrome?

Can I create an eSignature for the chiller plant log sheet pdf download in Gmail?

How do I fill out chiller inspection report using my mobile device?

What is chiller log sheet excel?

Who is required to file chiller log sheet excel?

How to fill out chiller log sheet excel?

What is the purpose of chiller log sheet excel?

What information must be reported on chiller log sheet excel?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.