Inspection 4 Industry Welding Log Quality Control Form 2012-2025 free printable template

Show details

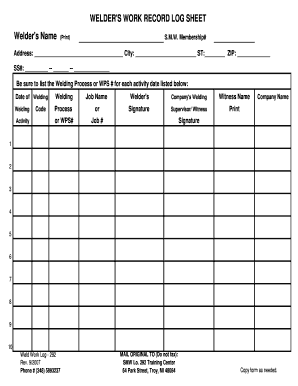

Project: Client: Report No.: WELDING LOG Contractor: Date: Ref. Standard: Page 1 of 1 Doc. No.: Plant×Location: Abbreviation: B: Butt Weld, S: Socket Weld, T: Seal ...

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign weld log template form

Edit your estimate sheets form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your welder log book sample form via URL. You can also download, print, or export forms to your preferred cloud storage service.

Editing weld log örneği online

Follow the guidelines below to benefit from a competent PDF editor:

1

Create an account. Begin by choosing Start Free Trial and, if you are a new user, establish a profile.

2

Upload a file. Select Add New on your Dashboard and upload a file from your device or import it from the cloud, online, or internal mail. Then click Edit.

3

Edit welding log sheet pdf form. Replace text, adding objects, rearranging pages, and more. Then select the Documents tab to combine, divide, lock or unlock the file.

4

Get your file. When you find your file in the docs list, click on its name and choose how you want to save it. To get the PDF, you can save it, send an email with it, or move it to the cloud.

With pdfFiller, it's always easy to work with documents. Try it!

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out welding logs form

How to fill out Inspection 4 Industry Welding Log Quality Control

01

Gather all necessary project documents and specifications.

02

Ensure that you have the latest version of Inspection 4 Industry Welding Log Quality Control form.

03

Begin with filling out the identification details, including project name and date.

04

Document the specific welding operations performed, including welding type and techniques used.

05

Record the names and qualifications of welders involved in the welding process.

06

Note down the parameters of welding such as voltage, amperage, and travel speed.

07

Include any inspection results, non-conformances, or corrective actions taken during the welding process.

08

Sign and date the form after completing all entries to validate the log's authenticity.

09

Store the log in a designated location for future reference and compliance.

Who needs Inspection 4 Industry Welding Log Quality Control?

01

Welders and welding inspectors to track and verify welding quality.

02

Quality control personnel to ensure compliance with industry standards.

03

Project managers to maintain oversight of welding operations.

04

Regulatory bodies that require documentation of welding processes.

05

Clients who need assurance of the quality and compliance of welding work performed.

Fill

form

: Try Risk Free

People Also Ask about

What are records of welding?

A record of welding variables used to produce an acceptable test weldment and the results of tests con-ducted on the weldment to qualify a welding procedure specification.

What is a weld log?

Weld logs contain the data specific to each individual weld. Normally a weld log sheet would contain all of the welding information for the welds on a specific isometric drawing. At the top of any weld log, you'll usually find client specific project specific information, i.e. project number, job number, etc.

What is weld records?

The documented record of a weld design is known as the Procedure Qualification Record (PQR, WPQR). A technical review of Welding Procedure documents is essential to ensure the design is compliant to WHS and Industry Standards.

Why is this information in the weld log important?

The weld mapping process also documents important information associated with the project in the form of a weld log. This documentation is similar to a spreadsheet and accompanies the weld map to show who worked on the piece, what was done, and in what sequence, along with other information.

How do you draw a weld map?

0:00 1:14 Then simply click and drag the mouse to draw. You need to enter the weld number for the first weld.MoreThen simply click and drag the mouse to draw. You need to enter the weld number for the first weld. And the subsequent welds will be incremented.

Why is a weld log important?

The advantage of the weld log is that it documents the who, what, when, and how of the weld. In some limited cases, weld details are included on the map, and no separate log is generated. In these situations, the project requirements are minimal and may only require one or two properties to be associated with the weld.

What is a welding map?

What is a Weld Map? A weld map is an extension of a technical drawing that outlines the number of welds, the types of weld joints, and their locations on a fabrication. The weld mapping process also documents important information associated with the project in the form of a weld log.

What is the importance on how to properly evaluate a weld?

It is important to check welds for quality, as this may have an impact on the way the repair will stand the test of time or another collision. Some things to look for include porosity, penetration, cleanliness, and incomplete welds. Any of these defects will weaken the weld and may cause a repair to fail.

What is required on a weld map?

Weld map should contain information such as its design (WPS), production (welders, their qualifications, date welded), quality (visual inspection, NDE), drawing and item number, and the information about the materials joined (heat numbers of materials & batch numbers of welding filler metals).

Our user reviews speak for themselves

Read more or give pdfFiller a try to experience the benefits for yourself

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I get weld log form?

The premium version of pdfFiller gives you access to a huge library of fillable forms (more than 25 million fillable templates). You can download, fill out, print, and sign them all. State-specific weld log form and other forms will be easy to find in the library. Find the template you need and use advanced editing tools to make it your own.

How do I fill out the weld log form form on my smartphone?

You can quickly make and fill out legal forms with the help of the pdfFiller app on your phone. Complete and sign weld log form and other documents on your mobile device using the application. If you want to learn more about how the PDF editor works, go to pdfFiller.com.

Can I edit weld log form on an iOS device?

You can. Using the pdfFiller iOS app, you can edit, distribute, and sign weld log form. Install it in seconds at the Apple Store. The app is free, but you must register to buy a subscription or start a free trial.

What is Inspection 4 Industry Welding Log Quality Control?

Inspection 4 Industry Welding Log Quality Control refers to the systematic process of evaluating and documenting the quality and integrity of welding performed in industrial settings. It involves monitoring compliance with specified standards and regulations to ensure that welds are of high quality and suitable for their intended purposes.

Who is required to file Inspection 4 Industry Welding Log Quality Control?

Typically, contractors, welders, and organizations engaged in welding operations are required to file the Inspection 4 Industry Welding Log Quality Control. This includes any party responsible for performing or overseeing welding work in compliance with industry regulations and standards.

How to fill out Inspection 4 Industry Welding Log Quality Control?

Filling out the Inspection 4 Industry Welding Log Quality Control involves accurately documenting specific details such as the date of the inspection, the type of weld performed, the materials used, the welder's identification, and results of any tests or evaluations conducted. It is important to follow the established format and guidelines provided for the log.

What is the purpose of Inspection 4 Industry Welding Log Quality Control?

The purpose of Inspection 4 Industry Welding Log Quality Control is to ensure that all welding activities meet the required safety and quality standards, to track compliance, and to provide a record of inspections that can be referenced for future audits or investigations.

What information must be reported on Inspection 4 Industry Welding Log Quality Control?

Information that must be reported on the Inspection 4 Industry Welding Log Quality Control includes the date of inspection, the name and identification number of the welder, the specifications of the weld, materials used, results of tests and inspections, and any corrective actions taken if defects are found.

Fill out your weld log form online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Weld Log Form is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.