Get the free spot verification proforma

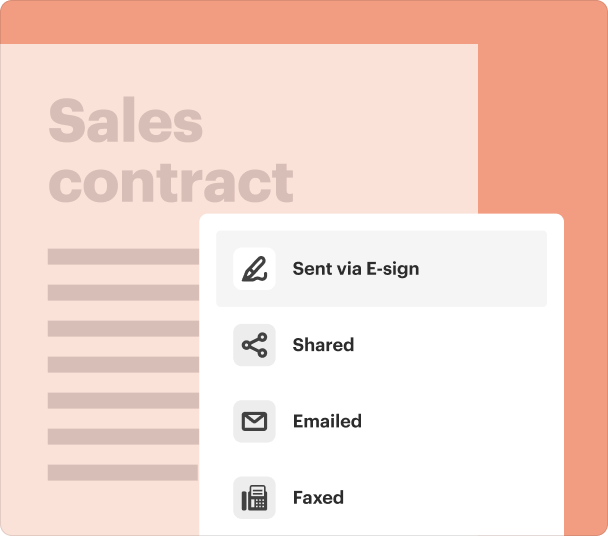

Fill out, sign, and share forms from a single PDF platform

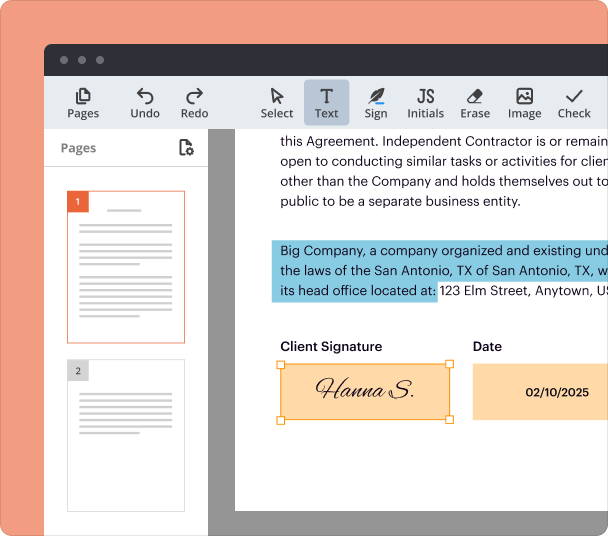

Edit and sign in one place

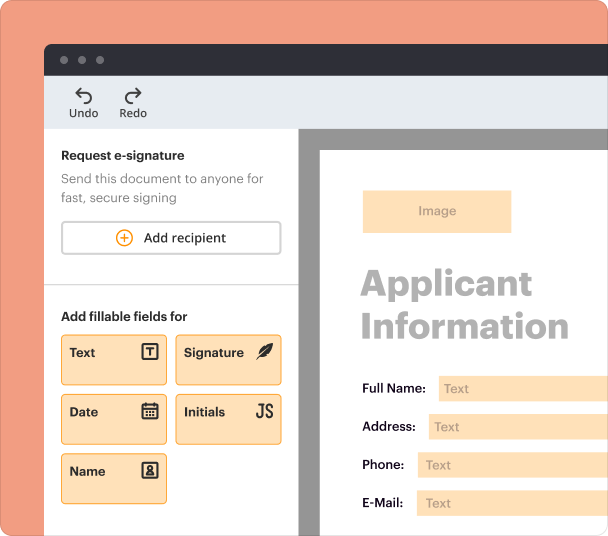

Create professional forms

Simplify data collection

Manage forms centrally

Why pdfFiller is the best tool for your documents and forms

End-to-end document management

Accessible from anywhere

Secure and compliant

Spot Verification Proforma Form Guide

What is a Spot Verification Proforma Form?

A spot verification proforma form is a standardized document used to record inspections and assessments conducted at various work sites. Its primary purpose is to ensure accuracy and compliance in inspections, which is critical in preventing accidents and maintaining safety standards. Industries such as construction, manufacturing, and energy often utilize this form to document safety checks and operational compliance.

-

This form streamlines the process of conducting inspections by providing a structured way to gather necessary data.

-

Accurate documentation is essential to ensure all safety measures are followed and to prevent legal repercussions.

-

Industries including construction, oil and gas, and manufacturing heavily rely on spot verification forms for regulatory compliance.

What are the key sections of the Spot Verification Proforma Form?

The spot verification proforma form is divided into several key sections, each serving an important role in the inspection process. Understanding these sections is crucial for accurate and effective documentation.

-

Provides a reference point for the specific project, aiding in organization and accountability.

-

Allows for the identification of responsible parties during the inspection.

-

Essential for tracking inspections over time and ensuring that inspections are up-to-date.

-

Helps tailor inspections to specific site conditions and operational challenges.

-

Establishes compliance and authority of the inspector, enhancing trust in the inspection outcomes.

How can pdfFiller help in editing the Spot Verification Proforma Form?

Using pdfFiller simplifies the process of editing the spot verification proforma form, providing users with intuitive tools tailored for online document management. This platform enables users to edit text fields, incorporate eSignatures, and fill out forms interactively, enhancing overall efficiency.

-

Accessing the form on pdfFiller is user-friendly, guiding you through every step.

-

Simply click on the text areas to modify any information needed without hassle.

-

Enhances compliance and simplifies collaborations, making the document legally binding.

-

Users can easily navigate the form and fill it out online, reducing errors and saving time.

How can you fill out the Spot Inspection Report effectively?

Filling out the spot inspection report involves adhering to specific requirements and criteria to ensure comprehensive evaluations. By following laid out guidelines, users can enhance clarity and reliability in their reports.

-

Include both temporary and permanent instructions to ensure all critical aspects are addressed.

-

Differentiate between compliance and non-compliance to ensure clarity in evaluations.

-

Establish clear scoring systems to interpret findings easily and take appropriate actions.

-

Utilize examples for each section to better understand how to document findings.

What are the specific requirements for high-risk non-routine activities?

High-risk non-routine activities require stringent documentation and safety protocols to mitigate potential hazards. Identifying these activities early helps in planning and preparation.

-

Understanding which tasks fall under high-risk categories is critical for safety management.

-

Comprehensive documentation and safety plans are necessary to ensure compliance and safety.

-

Proper equipment and training are paramount in ensuring personnel safety during these tasks.

-

Establishing clear communication plans can prevent confusion and enhance safety during emergencies.

What are the best practices for conducting spot inspections?

Implementing best practices can greatly enhance the effectiveness of spot inspections. These practices emphasize safety, communication, and preparation.

-

Using tool box talks can effectively communicate safety practices to workers before inspections.

-

Using appropriate personal protective equipment ensures safety during inspections.

-

Regular checks on tools decrease the risk of malfunction or accidents.

-

Controlling site access can significantly reduce the risk of unauthorized entry and potential accidents.

What compliance and regulatory considerations should be taken into account?

Understanding compliance obligations is crucial for any organization. Engaging with relevant health and safety executives can clarify these obligations and provide guidance.

-

Compliance requirements can vary, so it’s essential to understand local regulations.

-

Establishing a relationship with health and safety staff can provide necessary insights into compliance.

-

Company manuals serve as important resources for ensuring compliance and clarity.

-

A handy reference checklist can streamline the compliance process and ensure thorough documentation.

How to manage reporting and documents using pdfFiller?

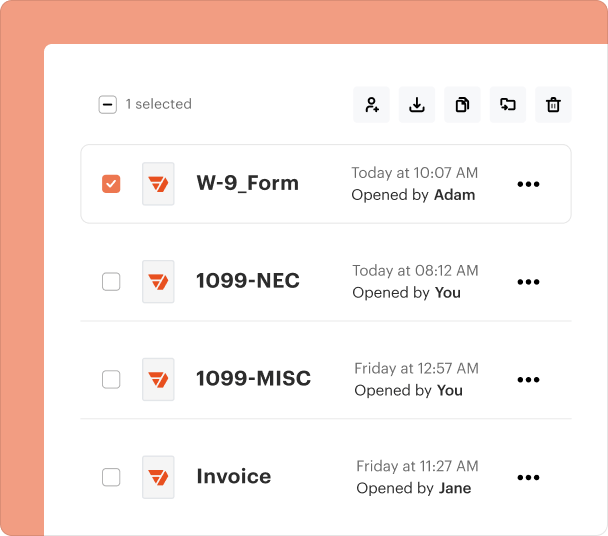

pdfFiller enhances the management of reports and documents, providing a cloud-based solution for collaboration and storage. You can share reports easily with stakeholders, ensuring transparency across teams.

-

Utilize collaborative tools to streamline the inspection process among team members.

-

Cloud storage capability allows for easy access and organization of all inspection forms.

-

Effortlessly share completed reports with stakeholders for immediate feedback and transparency.

-

Keep track of all revisions ensuring the integrity of the documents throughout the life cycle.

Frequently Asked Questions about spot verification proforma rfos dws

What is the main purpose of a spot verification proforma form?

The main purpose is to document inspections and assess compliance with safety and operational standards. By ensuring accurate data is collected, organizations can prevent accidents and maintain compliance with regulations.

How do I fill out the spot verification proforma form using pdfFiller?

To fill out the form using pdfFiller, simply access the form from your dashboard, click on the editable fields, and input the necessary data. You can also incorporate eSignatures for added convenience.

What are the requirements for high-risk activities?

High-risk activities need exhaustive documentation and must include safety plans and equipment requirements. It’s paramount to engage staff early to establish necessary safeguards.

How can I ensure compliance with regulations?

Understanding local compliance obligations is key. Regular engagement with health and safety officers, along with using company manuals, can provide clarity on compliance requirements.

What are the benefits of using pdfFiller for document management?

pdfFiller offers cloud-based document management, allowing for seamless collaboration, easy sharing, and secure storage of your forms. It enhances efficiency and helps maintain the integrity of your documents.

pdfFiller scores top ratings on review platforms