Get the free welding procedure specification format in excel download

Get, Create, Make and Sign welding procedure specification template excel form

How to edit wps saldatura excel online

Uncompromising security for your PDF editing and eSignature needs

How to fill out welding procedure specification format

How to fill out welding procedure specification format:

Who needs welding procedure specification format?

Video instructions and help with filling out and completing welding procedure specification format in excel download

Instructions and Help about welding procedure specification format

This presentation I'm going to try and cover as me section 9 P numbers F numbers and a numbers my name is Gary pace I'm a professional engineer in CW I am out of Katy Texas you can see there's my contact information and my website Texas welding engineering comm going to try and clear up maybe some questions about P numbers F numbers and a numbers or maybe just help you understand them a little better if you're a newcomer to this and wondering what the heck do we got going on, so I'm going to try and help you navigate a couple of the nuances involved in P numbers F numbers and a numbers examples of essential variables these are some examples of essential variables for gas metal arc welding and flux-cored arc welding which under as me section 9 gas metal arc welding and flux-cored arc welding are the same process considered the same process even though there are some differences under AQMI section 9 they call it the same, so you'd have shielding gas mixture or percentage of the composition is one of the essential variables post weld heat treatment, and then we're going to talk about the three we're going to talk about in this presentation our P number F number and a number P number is your base material grouping, so it could be something like a carbon steel a titanium alloy copper aluminum nickel alloys whatever they're all broken down into a specific P number grouping F number is the filler material grouping so if you're using a nickel based alloy you could have an F 22 or f42 aluminum would be an F 22 but not every material that has an F number has an A number the examples that I just gave you of nickel and nickel alloys aluminum's coppers Titanium's they're non-ferrous metals, so they don't have a number to have and number you have to be a ferrous material austenite stainless steel a duplex stainless steel a high alloy steel a garden-variety carbon steel if you're a ferrous alloy ferrous meaning the bulk of the material is made up of iron you're going to have a number on that filler material, so that's where a numbers come in so if you're dealing with titanium zirconium or one of the other non-ferrous materials you don't have a number F number all filler materials have them and then P numbers all base materials have them, but a number is just for ferrous weld materials here's a procedure qualification record so here's where we've got our essential variables our p number f number and a number listed on here so in blue in the little blue circle we've got our p numbers, so we're welding up p number eight to a p number eight for this procedure qualification record and the filler metal we're going to deposit in that weld is F five type filler metal, and it's going to be a number eight the weld metal analysis the chemical analysis on that is going to be a number eight if we were doing something that was aluminum or titanium or a non-ferrous metal we wouldn't have an A number we could leave that blank put none or not applicable so here's's what a...

Our user reviews speak for themselves

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I modify my welding procedure specification format in Gmail?

How do I make edits in welding procedure specification format without leaving Chrome?

How can I edit welding procedure specification format on a smartphone?

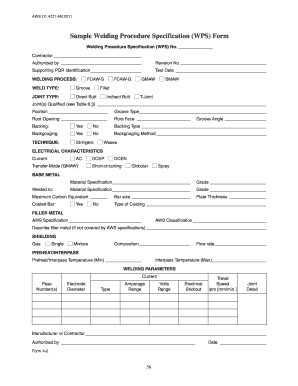

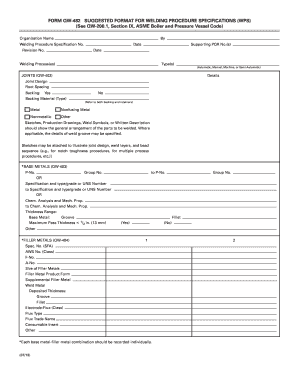

What is welding procedure specification format?

Who is required to file welding procedure specification format?

How to fill out welding procedure specification format?

What is the purpose of welding procedure specification format?

What information must be reported on welding procedure specification format?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.