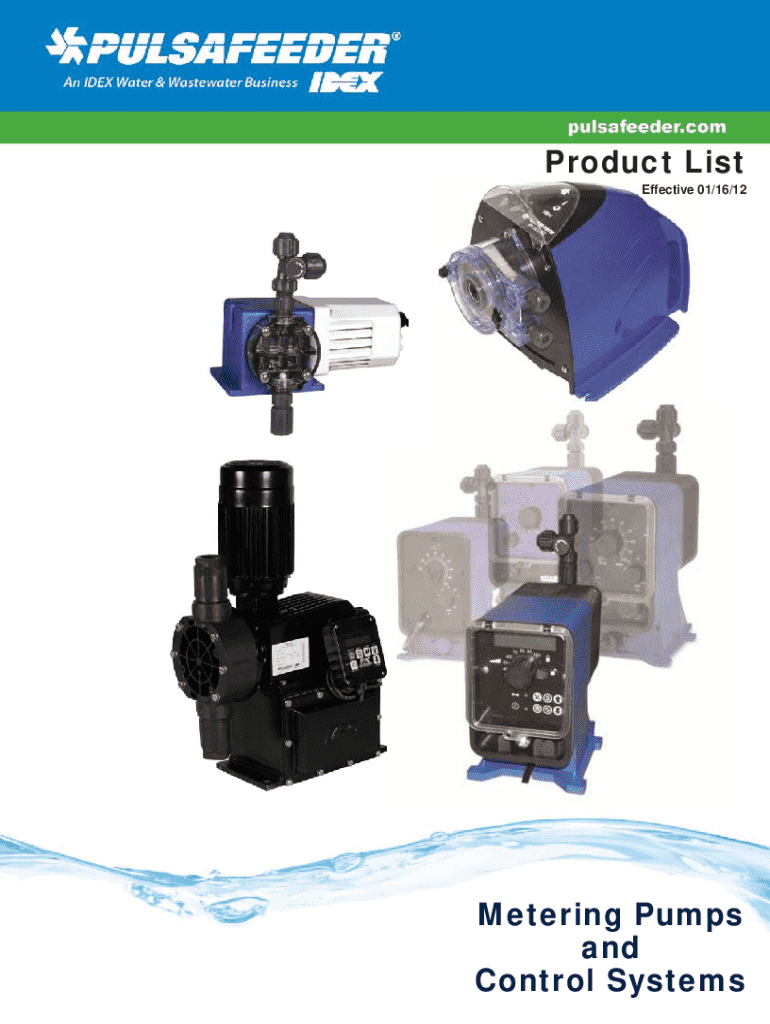

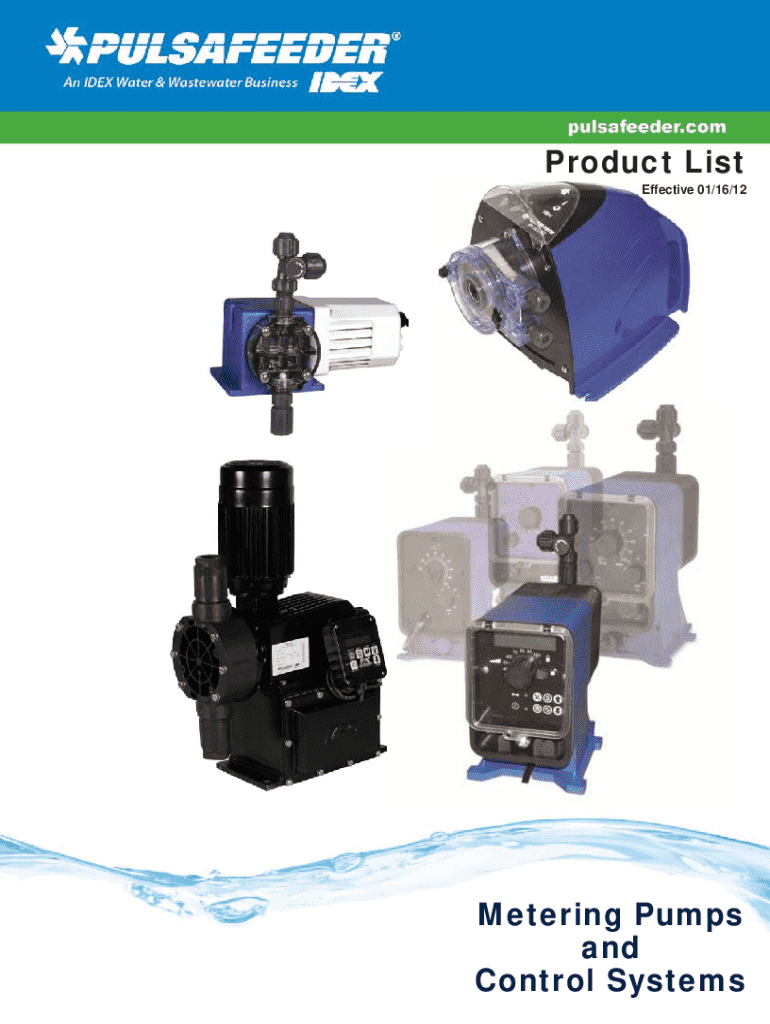

Get the free Product List Metering Pumps and Control Systems

Get, Create, Make and Sign product list metering pumps

Editing product list metering pumps online

Uncompromising security for your PDF editing and eSignature needs

How to fill out product list metering pumps

How to fill out product list metering pumps

Who needs product list metering pumps?

Metering Pumps Form: A Comprehensive Guide

Understanding metering pumps

Metering pumps are essential devices used to deliver precise amounts of liquid materials in various applications. They function by accurately controlling the flow rate and volume of liquid dispensed, ensuring efficiency and precision in various industries. Typically, metering pumps operate through mechanical or motor-driven methods, enabling them to suit diverse needs and specifications.

Key components of metering pumps include the pump head, diaphragm, drive mechanism, and connection fittings. The pump head determines the volume and pressure of the liquid, while the diaphragm acts as a barrier to prevent unwanted mixing of fluids. Applications of metering pumps span several industries, particularly:

Types of metering pumps

Understanding the various types of metering pumps is crucial for selecting the right one for specific applications. The most commonly used types include mechanical metering pumps, motor-driven pumps, peristaltic pumps, and diaphragm pumps.

Mechanical metering pumps operate through a manual mechanism and are ideal for low-to-medium flow applications. In contrast, motor-driven metering pumps offer enhanced accuracy and can handle a wider range of flow rates, making them suitable for both small-scale and large-scale operations.

Choosing the right metering pump

When selecting a metering pump, several critical factors must be considered to ensure optimal performance. Begin by assessing your flow rate requirements, as different pumps offer varying capacities. Additionally, understanding the characteristics of the fluid, including viscosity, pH, and temperature, can influence the choice of the pump.

The application environment also plays a significant role—consider factors like space limitations, possible exposure to corrosive elements, and the need for remote monitoring capabilities.

The metering pump selection form

The metering pump selection form serves as a critical tool for collecting essential information needed before making a purchasing decision. By utilizing this form, teams can streamline the process and ensure that all necessary details are captured accurately, ultimately leading to better choices.

Key information typically required in the form includes the type of pump needed, specific flow rate and pressure requirements, and environmental conditions such as temperature and potential hazards. Empowering teams with this structured approach not only saves time but also enhances accuracy and efficiency in pump selection.

How to fill out the metering pump form

Filling out the metering pump form accurately is essential for effective processing and ensures that your requirements are understood. Begin with personal information, including contact details and company identification. This basic information enables seamless communication throughout the selection process.

Next, specify your application details, carefully documenting the type of metering pump required along with all essential specifications. If customization options are available, it's important to explore those to fully meet your needs.

To ensure accuracy, double-check your entries and consider using tools like pdfFiller, known for assisting users in crafting precise documentation efficiently.

Managing and editing your metering pump form

Once you've completed the metering pump form, utilizing document management tools like pdfFiller allows for enhancing and editing your submissions effectively. Users can take advantage of a range of editing features, such as modifying text and including digital signatures, ensuring that all required elements are present before submission.

Additionally, pdfFiller's collaborative features make it easy for team members to share the form and provide feedback. This promotes transparency and ensures that everyone involved is aligned on the pump selection process.

Case studies: Metering pump applications in action

Real-world applications of metering pumps showcase their vast potential and effective use across various sectors. For example, in chemical metering within manufacturing industries, metering pumps have been pivotal in ensuring the correct dosage of reactive substances, which minimizes waste and maximizes production efficiency.

Similarly, wastewater treatment facilities depend heavily on metering pumps to optimize chemical dosing processes. Success stories from these industries reveal how reliable metering pumps have substantially improved operational efficiency and cost-effectiveness.

Frequently asked questions about metering pumps

Addressing common queries about metering pumps is vital for potential users. Many seek to understand the maintenance requirements associated with these devices, as well as troubleshooting tips for common issues. Users also often have questions regarding compatibility with various fluids and the expected lifespan of the equipment.

Experts recommend routine checks and maintenance for optimal functionality, while also providing customized solutions for specific fluid applications. Customer feedback often highlights the reliability of metering pumps and their essential role in streamlined operations.

Additional features of pdfFiller for document handling

pdfFiller presents a suite of features designed to enhance document handling, particularly for forms like the metering pump selection form. One significant advantage lies in its cloud-based solution, which allows users to access their documents from anywhere, promoting flexibility in managing business operations.

Moreover, pdfFiller integrates seamlessly with other tools, allowing users to maintain workflows efficiently. With built-in security features, users can trust that their sensitive information is safeguarded throughout the document handling process.

Connect with experts

For those looking to delve deeper into metering pumps, reaching out to experts is crucial. Depending on your specific needs, these professionals can offer insights, answer inquiries, and even help customize solutions. Engaging with them ensures that you are making informed decisions based on your unique applications and operational needs.

Moreover, establishing a connection with experts can pave the way for consultations, demonstrations, and additional support tailored to enhance your understanding and effective management of metering pumps.

Resources and references

For further information on metering pumps and their applications, accessing brochures and technical specifications can provide valuable insights. Additionally, video tutorials focusing on form usage can enhance understanding for effective submissions, encouraging confidence in filling out the metering pump selection form.

Industry reports highlighting trends and developments in metering pump technology can also be instrumental for staying updated on best practices and innovative applications.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I edit product list metering pumps from Google Drive?

How do I make changes in product list metering pumps?

How do I edit product list metering pumps on an Android device?

What is product list metering pumps?

Who is required to file product list metering pumps?

How to fill out product list metering pumps?

What is the purpose of product list metering pumps?

What information must be reported on product list metering pumps?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.