Get the free Heated hoses for freeze prevention or temperature ...

Get, Create, Make and Sign heated hoses for ze

Editing heated hoses for ze online

Uncompromising security for your PDF editing and eSignature needs

How to fill out heated hoses for ze

How to fill out heated hoses for ze

Who needs heated hoses for ze?

Heated hoses for ze form: A comprehensive guide

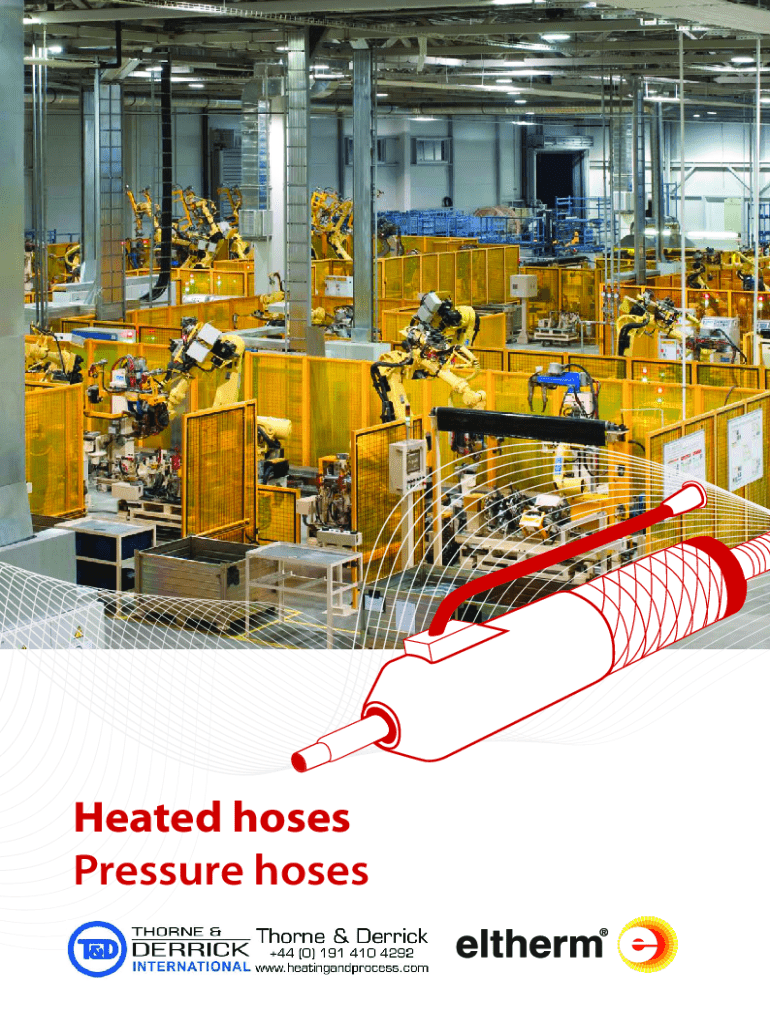

Understanding heated hoses

Heated hoses are specialized tubing systems designed to maintain fluid temperatures within specified limits, crucial for various applications. They are engineered to prevent the freezing of liquids in cold weather and ensure that substances can flow smoothly in environments that would otherwise hinder conventional hoses.

In industries such as agriculture, food processing, and petrochemicals, heated hoses play a vital role. They enable the transport of vital fluids, maintain operational efficiency, and mitigate problems that arise from subpar temperatures.

Importance of heated hoses in cold weather conditions

Cold temperature can cause fluids to congeal and hinder operations significantly. Heated hoses provide a reliable solution by preventing the freezing of water, oils, and other liquids. This not only preserves the functionality of the fluids but also extends the longevity of the hose itself.

Choosing the right heated hose for your needs

Selecting the appropriate heated hose involves understanding specific requirements and environmental factors. Key considerations include the desired temperature range, hose length, and diameter, and compatibility with the materials being transported.

Each type of heated hose serves different applications. You must assess your project to ensure that the selected hose can adequately support not just flow, but also the temperature demands required.

Types of heated hoses available

Heated hose construction

The construction of heated hoses is a testament to the technological advances in hose manufacturing. Key components, such as the base hose material and heating elements, dictate the overall performance and durability of the hose.

How hose construction affects performance

The materials and design features of a heated hose directly influence its operational efficiency. For example, a hose designed with superior insulation materials will generally perform better in extreme conditions, thus minimizing energy loss and ensuring uniform heating.

Installation and maintenance

Correct installation of heated hoses is crucial for optimal functionality. A detailed step-by-step process is vital to ensure that the hose fits its application correctly and that it operates efficiently.

Post-installation, routine maintenance significantly affects the longevity and efficiency of heated hoses. Regular checks should be conducted to ensure that all components are functional and clean.

Maintenance tips for longevity

Safety considerations and compliance

Safety plays a paramount role in the operation of heated hoses. Understanding industry safety ratings and standards helps ensure that selected products meet required guidelines.

Potential hazards

Heated hoses, while beneficial, possess hazards if not managed properly. Risk factors can arise from improper use or installation in explosive atmospheres, necessitating strict adherence to safety protocols.

Specialized applications of heated hoses

Specific industries leverage heated hoses to enhance operational processes tailored to their unique requirements. In the food and beverage industry, for instance, maintaining fluid temperatures is crucial for product quality.

Custom solutions for unique needs

Tailored solutions often address unique operational challenges experienced by different sectors. Engaging with suppliers can facilitate customized installations that specifically meet workflow demands and safety requirements.

Frequently asked questions (FAQs)

Clients often have questions regarding the selection and usage of heated hoses. Knowing how to make informed choices assists users in optimizing their applications.

Product offerings and how to get started

pdfFiller offers an extensive range of heated hoses and accessories. From specific options designed for food processing to versatile models for industrial use, users can find exactly what they need.

How to create and manage your purchase with pdfFiller

Using pdfFiller's platform, customers can easily fill out, edit, and manage purchase documents for heated hoses. The platform’s capabilities for electronic signatures streamline the purchasing process.

Community engagement

Engagement with the user community enhances the understanding and application of heated hoses. pdfFiller encourages sharing experiences and feedback regarding products and services.

Connect with pdfFiller on social media

For users wanting the latest updates, connecting through social media channels provides access to promotional offers and news about heated hoses and product improvements.

Next steps

After understanding heated hoses and their applications, you can access pdfFiller’s products with ease. The platform offers straightforward options for checking out and processing orders.

Exploring additional resources on document management

pdfFiller provides further resources beyond heated hoses, offering guides on other equipment and forms. These resources can help you stay informed about best practices in document management and operations.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I modify heated hoses for ze without leaving Google Drive?

Can I sign the heated hoses for ze electronically in Chrome?

How do I fill out heated hoses for ze on an Android device?

What is heated hoses for ze?

Who is required to file heated hoses for ze?

How to fill out heated hoses for ze?

What is the purpose of heated hoses for ze?

What information must be reported on heated hoses for ze?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.