Comprehensive Guide to Machinery Centralized Control System Forms

Understanding the machinery centralized control system

A machinery centralized control system is a sophisticated setup that allows for the monitoring and management of various industrial machines from a single, unified control point. This system integrates all machinery operations, facilitating streamlined processes and enhanced operational efficiency. In sectors where timely response to machinery performance is crucial, these systems offer real-time data and control, which can be essential for maximizing productivity.

The importance of a centralized control system cannot be overstated. It ensures that operations run smoothly, reduces downtime, and minimizes the risks of errors in decision-making. Through better data acquisition and analysis, organizations benefit from improved predictive maintenance strategies and optimized resource allocation. This results in substantial operational cost savings and increased reliability across manufacturing processes.

Key components of a machinery centralized control system

Understanding the core components of a machinery centralized control system is essential for effective implementation and management. The system typically consists of the following key components:

Central Control Unit (CCU) - This serves as the brain of the control system, processing and analyzing data from various machinery.

User Interfaces and Interaction Points - These include dashboard displays that allow operators to interactively oversee and control machinery operations.

Sensors and Data Acquisition Tools - These instruments collect real-time data from machines, such as temperature, pressure, and operational efficiency.

Communication Networks and Protocols - Essential for ensuring seamless data exchange between various components and machines, enhancing the overall efficiency of the control system.

Benefits of implementing a centralized control system

Implementing a machinery centralized control system can lead to significant operational improvements across various industrial settings. The primary benefits include:

Enhanced Efficiency and Performance - Centralized control allows for synchronized machine operations, reducing bottlenecks.

Real-time Monitoring and Management - Operations managers can monitor system performance in real time, facilitating immediate intervention when issues arise.

Improved Data Accuracy and Analytics - With all data centralized, companies can conduct more robust analytics, leading to better insights and actions.

Streamlining Operations Across Teams or Departments - Improved communication and data sharing enhance cooperation among different functional teams.

Types of machinery centralized control systems

Different types of centralized control systems cater to various industrial needs, including:

Distributed Control Systems (DCS) - Ideal for extensive industrial processes, enabling multiple control points to manage interconnected systems.

Supervisory Control and Data Acquisition (SCADA) - Excellent for monitoring large-scale operations across geographic locations.

Programmable Logic Controllers (PLC) - Specific control devices used in automation of electromechanical processes.

Hybrid Control Systems - A blend of control systems to offer versatility found in both DCS and SCADA.

When choosing a system, it is essential to evaluate the specific features and use cases of each type, facilitating better decision-making.

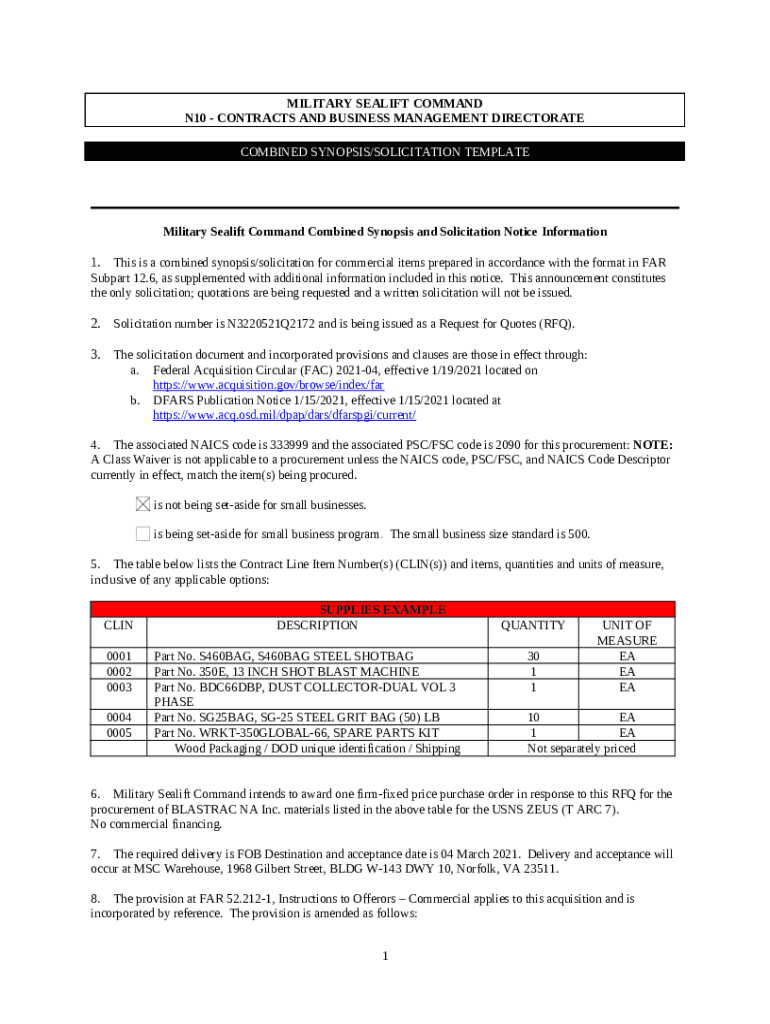

Steps to fill out the machinery centralized control system form

Filling out the machinery centralized control system form requires attention to detail and a structured approach. Here’s a step-by-step guide:

Gather Necessary Documents and Data - Collect all relevant information required for the form, including machine specifications and operational requirements.

Understand Form Field Requirements - Familiarize yourself with each section of the form to ensure nothing is overlooked.

Complete Each Section with Relevant Information - Be thorough while documenting specifications, including identifying Control Unit specifications and inputting communication protocols.

Edit and Review the Completed Form - Check for errors and ensure all fields are accurately filled.

Finalize and Sign the Document - Ensure the final version is appropriately authorized to proceed.

Tools for managing machinery centralized control system forms

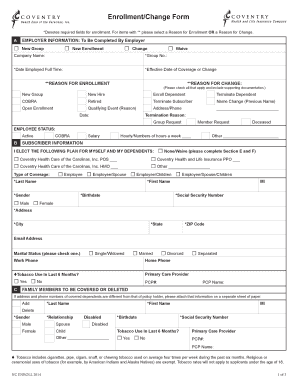

Efficient management of forms is crucial for seamless operations, and pdfFiller offers an array of features to facilitate this, including:

Editing PDFs - Easily modify documents as necessary to keep information current.

eSigning Capabilities - Sign documents digitally for quicker approvals.

Collaboration Tools - Work with team members in real-time for smoother completion of forms.

Cloud Access for Anytime, Anywhere Document Management - Access documents from any device at any time, enhancing flexibility.

When compared to other document management solutions, pdfFiller stands out for its comprehensive set of tools that boost productivity and streamline workflows.

Common challenges in centralized control system implementation

Implementing a centralized control system can present various challenges such as:

Technical Integration Issues - Merging existing systems with new technology can prove to be complex.

User Training and Adaptation - Employees may require extensive training to adapt to the new system.

Ongoing Maintenance and Support Needs - Keeping the system updated and operational necessitates a commitment to maintenance.

Addressing these challenges proactively can lead to a smoother implementation process and improved outcomes.

Case studies: Successful implementations of centralized control systems

Examining real-world implementations can provide valuable insights. For example, in the manufacturing sector, a well-known automobile manufacturer adopted a centralized control system that reduced operational downtime by 25%. This was achieved through enhanced real-time data analytics, enabling rapid response to any performance issues detected in machinery.

These case studies reveal that investing in a centralized control system can streamline operations and improve overall productivity, as seen in various industries from energy management to food processing. The key takeaway is that the benefits, particularly in terms of efficiency and cost savings, often far outweigh the challenges faced during implementation.

Future trends in machinery control systems

The future of machinery control systems is being shaped by several exciting trends, notably the integration of the Internet of Things (IoT) into industrial environments.

With IoT, machines can communicate and share data seamlessly, enhancing networked control systems and predictive maintenance capabilities. Additionally, advances in artificial intelligence and machine learning are making it possible to analyze complex data sets faster and more accurately than ever before, enabling more informed decision-making.

However, as systems become more interconnected, the importance of cybersecurity cannot be ignored. Companies must invest in robust security measures to protect their control systems from potential threats and vulnerabilities.

Best practices for using centralized control systems

To optimize the use of machinery centralized control systems, it is essential to adopt best practices such as:

Regular Updates and Maintenance Tips - Ensure that software and hardware components are consistently updated.

Training and Development for End Users - Invest in regular training sessions for users to help them stay updated on system features.

Strategies for Effective Data Management - Employ data governance policies to ensure accuracy and consistency in data across the system.

Implementing these practices not only improves operational efficiency but also enhances the reliability of the control system.

Frequently asked questions (FAQ) about machinery centralized control systems

1. What is the role of a centralized control system in machinery?

A centralized control system provides a unified platform for monitoring and managing the operation of multiple machines, promoting efficiency and reducing operational complexities.

2. How is data security managed within these systems?

Data security is managed through robust cybersecurity measures, including encryption, access controls, and regular system updates, which safeguard the integrity of machine and operational data.

3. What are the costs associated with implementing a centralized control system?

Costs can vary widely based on the complexity of the system, hardware requirements, and ongoing maintenance. It is crucial to conduct a cost-benefit analysis to understand the full scope of investment.

Related industry applications for machinery centralized control systems

Machinery centralized control systems have applications across numerous industries, including:

Agriculture - Automation of machinery for farming can improve crop yield and resource management.

Manufacturing - Streamlining production lines and optimizing resource allocation significantly enhance efficiency.

Shipping and Logistics - Providing real-time data for fleet and inventory management can reduce operational costs.

Renewable Energy Sector - Centralized control of renewable energy sources, such as solar panels or wind turbines, maximizes energy output and reliability.

Conclusion and next steps

The implementation of a machinery centralized control system can revolutionize operations across various industrial sectors. By effectively managing forms related to these systems using pdfFiller, organizations can ensure that they harness their full potential. Exploring and adapting these systems can lead to enhanced productivity and improved operational outcomes.