Get the free Pneumatic Chipping Hammers & Picks, by Chicago ...

Get, Create, Make and Sign pneumatic chipping hammers amp

Editing pneumatic chipping hammers amp online

Uncompromising security for your PDF editing and eSignature needs

How to fill out pneumatic chipping hammers amp

How to fill out pneumatic chipping hammers amp

Who needs pneumatic chipping hammers amp?

Pneumatic chipping hammers AMP form: A comprehensive guide

Understanding pneumatic chipping hammers

Pneumatic chipping hammers are essential tools powered by compressed air, designed primarily for tough and rigorous applications such as chiseling, breaking, and demolishing materials like concrete and asphalt. They operate through a mechanism that delivers rapid hammering action, making them efficient for a variety of tasks within numerous industries.

These tools are notably prevalent in construction, mining, and metalworking sectors, as they facilitate the removal of hard materials quickly. Using the right pneumatic chipping hammer is crucial, as it directly impacts the effectiveness, safety, and precision of the work being performed.

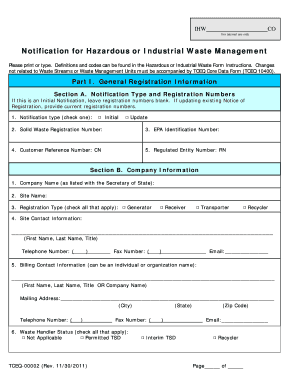

The pneumatic chipping hammer AMP form

Understanding the pneumatic chipping hammer AMP form is essential for those who leverage these tools within their operations. AMP forms serve as a structured way to document specifications, usage guidelines, and operational parameters, ensuring that users maximize the efficiency and safety of their equipment.

The key features of the pneumatic chipping hammer AMP form include input fields for technical specifications, safety instructions, and maintenance records. This system not only streamlines the documentation process but enhances the overall management of equipment usage.

Detailed specifications of pneumatic chipping hammers

When selecting a pneumatic chipping hammer, understanding its detailed specifications is pivotal. This includes considerations such as weight, dimensions, power output, and air pressure requirements, which collectively determine the tool’s effectiveness in various jobs.

Typically, pneumatic hammers come with specific performance ratings which notify users about the tool's capabilities. Knowing these specifications aids in matching the right tool to the task at hand, ensuring safety and efficient productivity.

Additional features such as vibration control and safety mechanisms should also be explored, as they contribute to user comfort and risk mitigation.

Step-by-step instructions for filling out the pneumatic chipping hammer AMP form

Filling out the pneumatic chipping hammer AMP form is straightforward when organized into manageable steps. Start by accessing the form via the appropriate online platform, where intuitive navigation leads you to fillable sections tailored specifically for your documentation needs.

Required information typically includes personal details as well as specific equipment characteristics. For accuracy, ensure you have all relevant data at your fingertips prior to starting the process.

Utilizing these organized steps will ensure a smooth and accurate fill-out process for your AMP form.

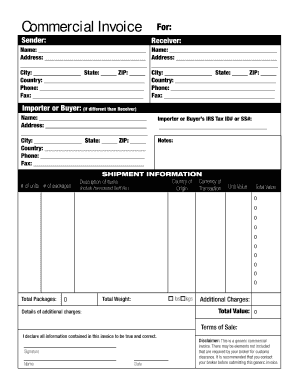

Using pdfFiller’s tools to manage your pneumatic chipping hammer AMP form

pdfFiller provides a robust platform where users can effortlessly manage their pneumatic chipping hammer AMP forms through various tools designed for customization and collaboration. The editing capabilities allow users to add or remove fields as needed, tailoring the form to specific requirements.

Additionally, eSigning features streamline signing processes, and the collaboration tools let you invite team members for collective inputs.

This comprehensive management of your pneumatic chipping hammer AMP forms through pdfFiller promotes efficiency and ensures that team members stay aligned.

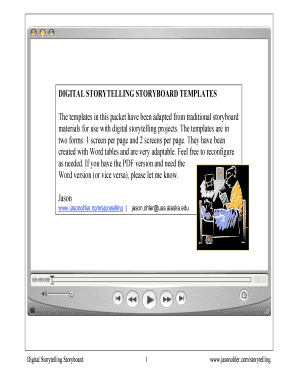

Managing pneumatic chipping hammer documentation effectively

Effective document management for your pneumatic chipping hammer AMP forms includes organized storage and systematic retrieval methods. Implementing a digital filing system within pdfFiller can keep your forms accessible while maintaining strict organization.

Best practices such as version tracking and maintaining an updated history for each document ensure that users have access to the most current and relevant information.

By focusing on structured management techniques, users can maximize the effectiveness of their pneumatic chipping hammer AMP forms.

Insights and tips for choosing a pneumatic chipping hammer

Choosing the right pneumatic chipping hammer goes beyond mere brand selection; it involves a thorough evaluation of operational needs. Users must consider factors such as job types, expected frequency of use, and the intensity of the tasks at hand.

Researching the market for recommended brands and reviewing customer feedback provides insight into performance ratings, reliability, and post-purchase support.

Incorporating these insights will equip users with the discerning knowledge needed to select the appropriate pneumatic chipping hammer.

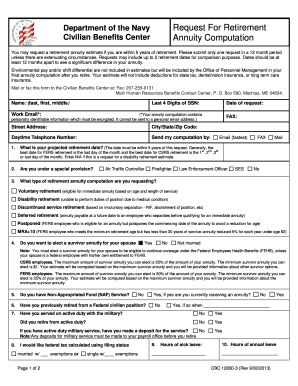

Frequently asked questions (FAQs)

There are common queries regarding the functionality and use of pneumatic chipping hammers that many users tend to have. This includes questions surrounding operational features, maintenance requirements, and specifics around the AMP form filling conditions.

Addressing such queries not only enhances user understanding but also mitigates any challenges experienced during usage or documentation.

Providing these insights establishes a clearer framework for users and enhances their overall experience.

Additional tools and resources

Beyond pneumatic chipping hammers, there are various related air tools that enhance operational efficiency across different applications. Exploring such tools can introduce advantages in workflow and productivity.

Additionally, training materials and video tutorials can serve as valuable resources for users to hone their skills in using pneumatic equipment effectively.

By utilizing these resources, users will be better prepared to make the most of their pneumatic chipping hammer and effectively complete their tasks.

Feedback and support

For any queries related to the pneumatic chipping hammer AMP form or its usage, users can reach out to dedicated support as necessary. Engaging with support teams often leads to efficient resolution of issues, further enhancing your experience.

User experiences and testimonials also add value by sharing insights into how others have effectively utilized the AMP form for managing their pneumatic chipping hammer documentation.

Encouraging feedback fosters community engagement and aids in refining the overall experience for all users.

Explore more products

With pneumatic chipping hammers at the forefront, there are several related air tools and equipment that could complement your existing toolkit. Expanding your product range not only enhances functionality but prepares you for diverse scenarios.

Consider evaluating accessories like safety gear and replacement parts, ensuring you have all necessities at hand for optimal performance.

By exploring these additional products, users can ensure they are fully equipped for any task that may arise.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I send pneumatic chipping hammers amp to be eSigned by others?

How do I execute pneumatic chipping hammers amp online?

How do I complete pneumatic chipping hammers amp on an iOS device?

What is pneumatic chipping hammers amp?

Who is required to file pneumatic chipping hammers amp?

How to fill out pneumatic chipping hammers amp?

What is the purpose of pneumatic chipping hammers amp?

What information must be reported on pneumatic chipping hammers amp?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.