Get the free High Performance Screw Jacks

Get, Create, Make and Sign high performance screw jacks

Editing high performance screw jacks online

Uncompromising security for your PDF editing and eSignature needs

How to fill out high performance screw jacks

How to fill out high performance screw jacks

Who needs high performance screw jacks?

High Performance Screw Jacks Form: How-to Guide

Understanding high performance screw jacks

High performance screw jacks play a critical role in the realm of mechanical engineering by converting rotational motion into linear displacement. Commonly used in applications requiring high reliability and precision, these components have paved the way for innovations in heavy-duty linear motion systems.

Screw jacks are designed to lift or lower heavy loads through rotational inputs. They are pivotal in scenarios where traditional lifting methods would either be impractical or impossible. In industrial settings, high performance screw jacks are vital components in assembly lines, heavy machinery, and infrastructure.

Key features of high performance screw jacks

When selecting high performance screw jacks, understanding the material used is essential. The durability of stainless steel screw jacks ensures longevity even within harsh conditions, making them ideal for sectors like aerospace and automotive.

Comparative material analysis highlights various options such as aluminum or plastic that may offer cost benefits but often lack the strength and longevity of stainless steel. Hence, selecting the right material can make a significant difference in performance and durability.

Advantageous design elements also enhance screw jack functionality. Features such as anti-backlash mechanisms ensure high degrees of precision in operations, reducing potential errors during critical applications. Additionally, integrating precision components, like mechanical counters and motors, facilitates better control and monitoring.

The customization potential of high performance screw jacks is another significant feature. Tailoring screw jacks to specific applications optimizes performance, catering to the unique demands of various industries.

Applications for high performance screw jacks

High performance screw jacks find extensive applications across a multitude of industries. In automotive assembly lines, they are vital for lifting car frames and precision installations. The reliability provided by efficient screw jacks leads to increased throughput and reduced downtimes.

In aerospace, where precision is paramount, screw jacks assist in the delicate balance and maintenance of aircraft, ensuring safety and compliance with strict regulations. Heavy machinery handling also benefits from the use of screw jacks, which manage substantial loads safely and effectively.

Case studies highlight successful implementations in various settings. One notable example is a large automotive manufacturer, where high performance screw jacks increased assembly line efficiency by 25%, demonstrating the transformative impact of these components.

Another example involves a construction firm using customized screw jacks that adapted to various lifting conditions, providing a lesson in the importance of tailored solutions for specific industry needs.

Selecting the right high performance screw jack

Choosing the correct high performance screw jack involves several critical considerations. First and foremost, calculating load capacity is imperative. Understanding the maximum load that the screw jack can safely handle is essential for avoiding mechanical failures.

Equally important is the fit for the operating environment. For instance, applications in chemically aggressive environments may require corrosion-resistant materials, while low-temperature settings may influence design choices.

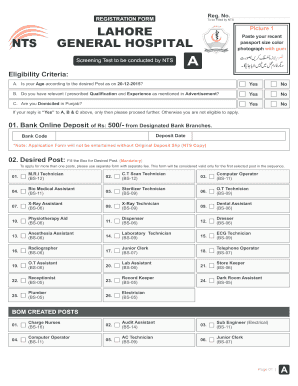

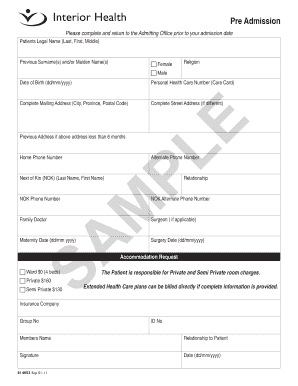

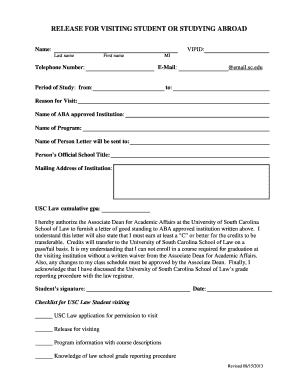

Filling out the high performance screw jacks form

Proper completion of the high performance screw jacks form is essential for obtaining accurate quotes and specifications. Each entry impacts the performance of the screw jack in the intended application, so clarity and accuracy are paramount.

A detailed breakdown of the form sections can help in understanding required fields. For instance, providing accurate load specifications and travel distances directly influences customization and performance scalability, ensuring that the screw jack meets all operational needs.

Tools and resources for high performance screw jacks

Utilize interactive tools for designing and configuring screw jacks more effectively. CAD configurations facilitate creating precise models, ensuring that your screw jack meets specific requirements while online calculators help analyze loads to verify calculations.

Further, accessing technical guides and documentation proves invaluable. The pdfFiller library offers high-quality templates that streamline document creation, while manuals provide essential information for installation and ongoing maintenance.

Collaboration and document management

Managing screw jack documentation can be simplified using pdfFiller. The platform allows users to edit, sign, and collaborate on forms effortlessly, ensuring that all stakeholders have the necessary information at their fingertips.

Cloud-based access further supports collaboration, offering pivotal security features while enabling users to handle their documents efficiently from virtually anywhere. This flexibility ensures that teams remain engaged while managing vital documents related to screw jacks.

Advanced considerations for high performance screw jacks

Troubleshooting common issues with screw jacks requires a methodical approach to identifying performance problems. Recognizing abnormal behaviors, such as unusual noise levels or inconsistent loading, can guide operators toward effective solutions.

Furthermore, keeping an eye on future trends in screw jack technology is vital. Innovations in materials like composite fibers and advancements in design techniques promise enhanced performance and lower costs. Engaging with manufacturers for expert support can provide valuable insights and extend the lifecycle of your screw jacks.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Can I create an electronic signature for the high performance screw jacks in Chrome?

How can I edit high performance screw jacks on a smartphone?

How can I fill out high performance screw jacks on an iOS device?

What is high performance screw jacks?

Who is required to file high performance screw jacks?

How to fill out high performance screw jacks?

What is the purpose of high performance screw jacks?

What information must be reported on high performance screw jacks?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.