Precision Metal Products and Precision Metal Form Explained

Overview of precision metal products

Precision metal products refer to components crafted with a high degree of accuracy, typically measuring down to microscopic tolerances. These products are crucial in sectors where exact specifications are non-negotiable, such as aerospace, automotive, and medical industries. Their importance is underscored by the intricate processes required to manufacture them, which ensure functionality, reliability, and performance.

Key characteristics of precision metal products include dimensional accuracy, material consistency, and surface finish quality. These attributes are vital to ensure that each part fits correctly, operates effectively, and meets customer specifications. For example, machined components used in high-speed machinery must maintain precise dimensions to avoid catastrophic failure.

Applications of precision metal products span various industries, from the manufacturing of turbine blades in aerospace to surgical instruments in healthcare. Each application demands a stringent adherence to quality standards, making the role of precision metal forming and fabrication all the more significant.

Types of precision metal forms

Understanding the different types of precision metal forms is essential for aligning the right manufacturing processes with your project needs. Here, we explore various types, starting with sheet metal forms.

Sheet metal forms

Sheet metal fabrication involves cutting, bending, and assembling metal sheets into desired shapes. It's widely used due to its versatility and cost-effectiveness. Common uses include cabinets, enclosures, and automotive body parts, benefiting from the flexibility that sheet metal offers for both design and production.

Custom fabricated components

Custom fabricated components provide tailored solutions for specific requirements. These components are particularly valuable when off-the-shelf parts do not meet exacting standards. For example, custom ease shapes are frequently used to create unique frames for electronic devices.

Standard metal forms

Standard metal forms include widely accepted specifications and designs that facilitate compatibility and interchangeability across industries. Examples range from standard bolts and nuts to specific sized plates. Utilizing standard forms reduces costs and speeds up production without compromising quality.

Understanding the metal fabrication process

The metal fabrication process encompasses several critical stages, each contributing to the final product's quality and precision. It begins with a well-defined plan and design.

Step 1: Design and planning

The importance of precise design cannot be overstated. Engineers and designers utilize CAD software for creating blueprints that define every aspect of the product. This digital blueprint lays the groundwork for all subsequent fabrication steps.

Step 2: Material selection

Material selection is paramount, impacting both performance and cost. Factors to consider include strength, weight, corrosion resistance, and manufacturing ease. Common materials such as aluminum and steel are favored for their availability and mechanical properties.

Step 3: Fabrication techniques

Different fabrication techniques include laser cutting, CNC machining, and various welding methods (TIG, MIG). Laser cutting offers precise dimensions with clean edges, while CNC machining is revered for its versatility in shaping complex parts. Welding processes contribute to the assembly of components, ensuring structural integrity.

Step 4: Quality control and testing

Quality control is vital in the fabrication process. Procedures to ensure precision include in-process inspection and final testing. Certification standards such as ISO ensure that the products meet the required specifications and regulatory guidelines.

Innovations in precision metal products

The field of precision metal products continuously evolves, driven by technological advances that enhance fabrication processes. Automation plays a crucial role, reducing production time and minimizing human error.

Advances in fabrication technology

Integration of AI and robotics in fabrication processes significantly improves efficiency and precision. For instance, robotic arms equipped with machine learning capabilities can adapt to varying production requirements by optimizing methodologies on the fly.

Sustainability practices in metal fabrication

Sustainability has become a focal point in metal fabrication. Companies are increasingly turning to eco-friendly materials and employing waste reduction techniques to promote environmentally responsible manufacturing. Practices such as recycling scraps and using biodegradable materials align with global sustainability goals.

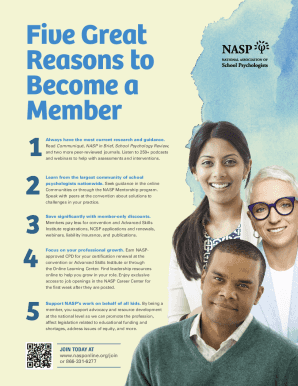

Selecting the right precision metal fabricator

Choosing a precision metal fabricator is critical for project success. Factors such as experience, technological capabilities, and industry reputation should guide your selection process.

Criteria for selection

Consider the following criteria when evaluating potential fabricators:

1. **Experience and expertise** in your specific industry — pertinent knowledge can enhance the outcome.

2. **Reputation and client testimonials** — learning about past successes helps gauge reliability.

Questions to ask potential fabricators

Engage potential fabricators with insightful questions, such as:

- What capabilities do you offer regarding precision machining and forming?

- What are the typical timelines for project completion?

- Can you provide examples of previous projects and relevant case studies?

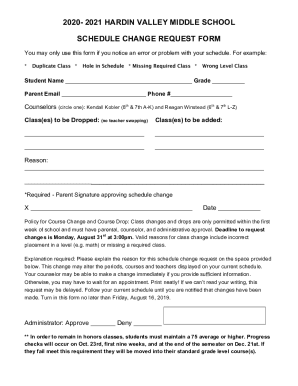

Utilizing technology for document management in metal fabrication

Effective document management is essential in streamlining communication and documentation processes in metal fabrication. Using advanced tools fosters collaboration and accuracy.

Choosing the right document creation tool

When selecting a document creation tool such as pdfFiller, look for essential features including collaboration capabilities, eSigning functionalities, and editing options. These tools can radically improve efficiency and reduce the back-and-forth often involved in document revisions.

Best practices for document management

Organizing files and templates efficiently ensures easy access when needed. Adopt practices for secure sharing and storage, such as encryption and backups, fortifying your valuable documents against loss or unauthorized access.

Interactive tools for precision metal projects

Interactive tools facilitate an efficient workflow in precision metal projects, enabling users to create and modify documents seamlessly. For instance, pdfFiller’s suite of interactive tools supports the entire documentation process.

Step-by-step guide to using pdfFiller for metal projects

Utilize pdfFiller effectively with a simple guide:

1. **Filling out design forms** — Select templates tailored to metal specifications.

2. **Using templates for project documentation** — Customize existing forms to suit your project through easy editing features.

Real-world applications and case studies

Examining successful precision metal projects illuminates innovative solutions and effective practices. For instance, a leading automotive manufacturer recently adopted new fabrication techniques to streamline production while maintaining quality, showcasing the importance of adaptability in a competitive market.

By analyzing diverse case studies, stakeholders can gain insights into best practices and potential challenges that are faced in the industry, better preparing them to approach their own precision metal projects.

Frequently asked questions (FAQs)

Understanding precision metal products and forms raises various questions among industry professionals. Common inquiries often include:

1. What level of precision can be achieved with metal fabrication?

2. How do I choose the right materials for my project?

3. What are the average lead times for custom precision metal products?

Clarifying these points not only educates but also instills confidence in stakeholders as they navigate their fabrication options and understand the processes involved.

Contacting your precision metal expert

For any inquiries or to discuss your project, reaching out to industry professionals is essential. Expertise in precision metal products can significantly influence your project's outcome, ensuring that all components meet or exceed expectations.

Consultations provide valuable insights into fabrication options, timelines, and costs, assisting in choosing the right path forward in your precision metal endeavor.