VSM-104 starters engine maintenance form: A comprehensive guide

Understanding the VSM-104 starters engine maintenance form

The VSM-104 starters engine maintenance form serves a crucial role in the aviation and engineering domains, particularly for maintenance personnel involved in aircraft and heavy equipment maintenance. This form is meticulously designed to ensure each engine starter undergoes comprehensive inspection, which enhances reliability and accountability in engine operations.

It is essential not only for recording maintenance activities but also for tracking compliance with regulatory requirements. By using the VSM-104 form, organizations can adequately document their engine maintenance history, which contributes significantly to the overall safety of operations.

Document and track engine performance and reliability.

Ensure compliance with aviation regulations and standards.

Facilitate effective communication among maintenance teams.

Who uses the VSM-104 form?

The VSM-104 form is primarily utilized by maintenance teams within aviation settings, including commercial airlines, cargo transport, and general aviation. Additionally, it is relevant for engineering firms that manage motorable equipment requiring regular inspections and maintenance. Users include licensed aircraft maintenance engineers, technicians, and safety inspectors whose roles involve ensuring engine operational integrity.

Apart from individuals directly involved in engine management, regulatory authorities also leverage the VSM-104 form to verify adherence to safety standards and maintenance protocols. This cross-utilization helps elevate the document's standing as an essential tool for safety and compliance, making its accuracy and completeness paramount.

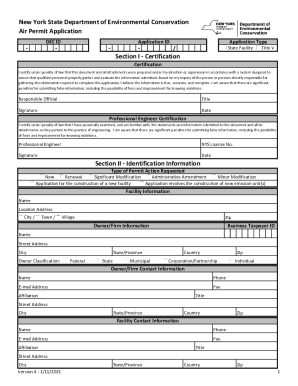

Key components of the VSM-104 form

A well-structured VSM-104 form comprises several sections, each designed to collect vital information regarding engine maintenance. Understanding these sections is critical for effective form utilization and helps guide maintenance procedures.

Engine identification details: Captures specifics like engine model, serial number, and aircraft or equipment information.

Maintenance procedures checklist: A detailed checklist allowing for systematic evaluation of engine conditions and required maintenance actions.

Inspection and troubleshooting guide: Provides guidance for identifying and documenting issues encountered during maintenance.

Sign-off and certification section: Essential for legal compliance and accountability, requiring the signatures of technicians and supervisors.

Each component holds significant importance. For instance, complete engine identification ensures that all records are accurate and traceable, while the maintenance checklist transforms a potentially chaotic process into a streamlined flow, fostering better communication and efficiency among maintenance teams.

Filling out the VSM-104 starters engine maintenance form

Filling out the VSM-104 form correctly is instrumental in maintaining thorough documentation of engine service. Starting off with preparation can make a significant difference in the process's efficiency.

Prepare necessary documentation: Gather required tools including maintenance manuals, previous maintenance records, and any relevant operational data.

Complete each section methodically: Focus on clarity and accuracy. Avoid ambiguous terms and strive for specific descriptions of maintenance actions performed.

Review and verify entries: Take the time to double-check the form for potential errors before finalizing. This could prevent costly consequences caused by misinformation.

These steps not only simplify the process but also reinforce accountability. Ensuring that technicians fill out the form correctly mitigates the risks associated with missing or inaccurate data, ultimately enhancing the longevity of engine operations.

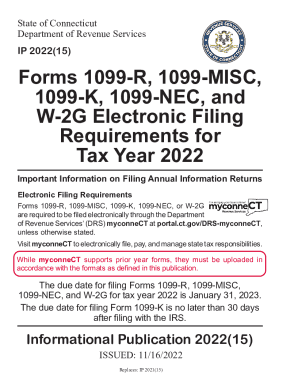

Editing and managing your VSM-104 form in pdfFiller

pdfFiller offers several features that make editing and managing the VSM-104 form hassle-free and efficient. As a cloud-based platform, it enables users to access the form anywhere, fostering flexibility in document management.

Utilize editable fields: pdfFiller allows users to fill out the VSM-104 form easily and make adjustments as needed without the hassle of physical paperwork.

Add comments and annotations: Users can leave notes regarding specific maintenance activities or highlight areas that require special attention.

Converting and exporting options: pdfFiller provides various formats (PDF, Word, etc.) for users to convert their documentation based on their needs, facilitating easy sharing across different platforms.

Overall, the interactive tools provided by pdfFiller enhance the user experience, encouraging proper documentation practices and encouraging a paperless approach.

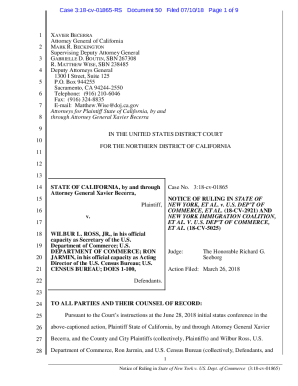

Signing the VSM-104 form

In today’s digital landscape, signing forms electronically has become a norm, and the VSM-104 form is no exception. PdfFiller integrates eSignature features that assure users of the legal validity of electronic signatures.

Add an eSignature: Users can simply drag and drop their signature or use the platform's signature creation tool to sign the document without printing it.

Ensure compliance through digital signing: E-signatures are legally accepted and provide enhanced security, maintaining an audit trail through automatic timestamping.

This streamlining of the signing process not only expedites workflows but also enhances accountability among maintenance personnel by ensuring that each form is properly authorized.

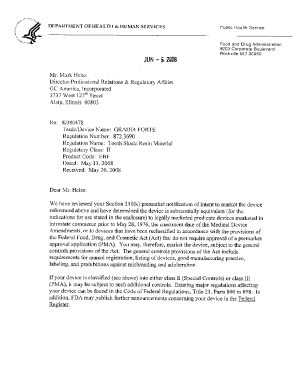

Troubleshooting common issues with the VSM-104 form

Despite its structured nature, users may encounter challenges when completing the VSM-104 form. Awareness of common issues can transform these hurdles into manageable tasks.

Missing information: Incomplete entries can hinder the effectiveness of the form, so it's critical to ensure that all sections are filled out completely.

Inaccurate entries: Errors in data entry can lead to compliance breaches, so always cross-check information with existing records to ensure accuracy.

Corrections process: Any mistakes made should be rectified immediately, with the original entry being flagged for clarity.

Addressing these issues promptly not only ensures smooth operations but also upholds the standards of accuracy and excellence in engine maintenance.

Collaborating on the VSM-104 starters engine maintenance form

Collaboration is a vital element when it comes to completing the VSM-104 form effectively. PdfFiller allows teams to share forms for real-time input, elevating the quality of documentation through multiple perspectives.

Options for collaboration: Users can share links or send the form directly through email, allowing team members to contribute.

Real-time editing scenarios: Group editing capabilities let multiple users work on the document simultaneously, which can catalyze quicker decision-making.

Incorporating feedback and finalizing documentation becomes straightforward with collaborative tools that pdfFiller facilitates, ensuring that the best practices are adhered to.

Best practices for using the VSM-104 starters engine maintenance form

Establishing best practices when using the VSM-104 form can significantly enhance its effectiveness as an engine maintenance tool. Regularly scheduled maintenance intervals should be set to ensure that documentation is kept up-to-date and reflects the current state of the engine.

Timely updates: Encourage your team to input data promptly after maintenance to maintain accuracy in the central database.

Review policies: Conduct periodic reviews of completed VSM-104 forms to identify areas for improvement in record-keeping and maintenance practices.

Training: Provide comprehensive training for new team members on the importance of accurate form completion and the nuances of the VSM-104 form.

Through these practices, teams can bolster their maintenance documentation efforts and ensure a high level of accountability and transparency.

Advanced features of pdfFiller for engine maintenance documentation

For organizations leveraging pdfFiller, the platform offers advanced features that facilitate engine maintenance documentation. Automation tools streamline processes, allowing for easier management of the VSM-104 form across multiple users.

Templates for future use: Users can create and save templates for standard maintenance practices, promoting consistency.

Automated reminders: Set up reminders for regular maintenance checks, ensuring that no tasks go overlooked.

Integration with other tools: pdfFiller integrates with existing software solutions, enabling users to incorporate the VSM-104 form seamlessly into their typical workflows.

These features put control into users’ hands, helping maintenance teams work more efficiently while ensuring document integrity.

Case studies and user experiences

Real-world applications of the VSM-104 form highlight its versatility and effectiveness in streamlining engine maintenance processes. User testimonials reflect positive experiences, notably in standardized reporting and enhanced communication among teams.

Increased efficiency: Users report reductions in wasted time due to improved workflows with collaborative capabilities.

Improved compliance: The ability to maintain accurate forms strengthens adherence to quality and safety standards as noted in several case studies.

Enhanced team accountability: By utilizing pdfFiller for the VSM-104 form, technicians feel a greater sense of ownership over their documentation.

Sharing these success stories demonstrates not only the utility of the VSM-104 form but also how it elevates maintenance operations to new heights.

The future of engine maintenance documentation

As technology evolves, the landscape of engine maintenance documentation is poised for continual development. Emerging trends include the shift towards entirely digital documentation practices that prioritize user-friendliness and integration.

Digital transformation: Organizations are increasingly adopting digital platforms to streamline their workflows and centralize documentation.

The prediction of centralized databases: Future forms like the VSM-104 could be housed within integrated systems that automatically aggregate data from multiple engines and platforms.

Enhanced analytics: As maintenance data becomes digitized, analytics tools will provide deeper insights into engine performance and maintenance trends.

These advancements highlight the importance of remaining adaptable and utilizing tools like pdfFiller to maintain proficiency in engine maintenance documentation.