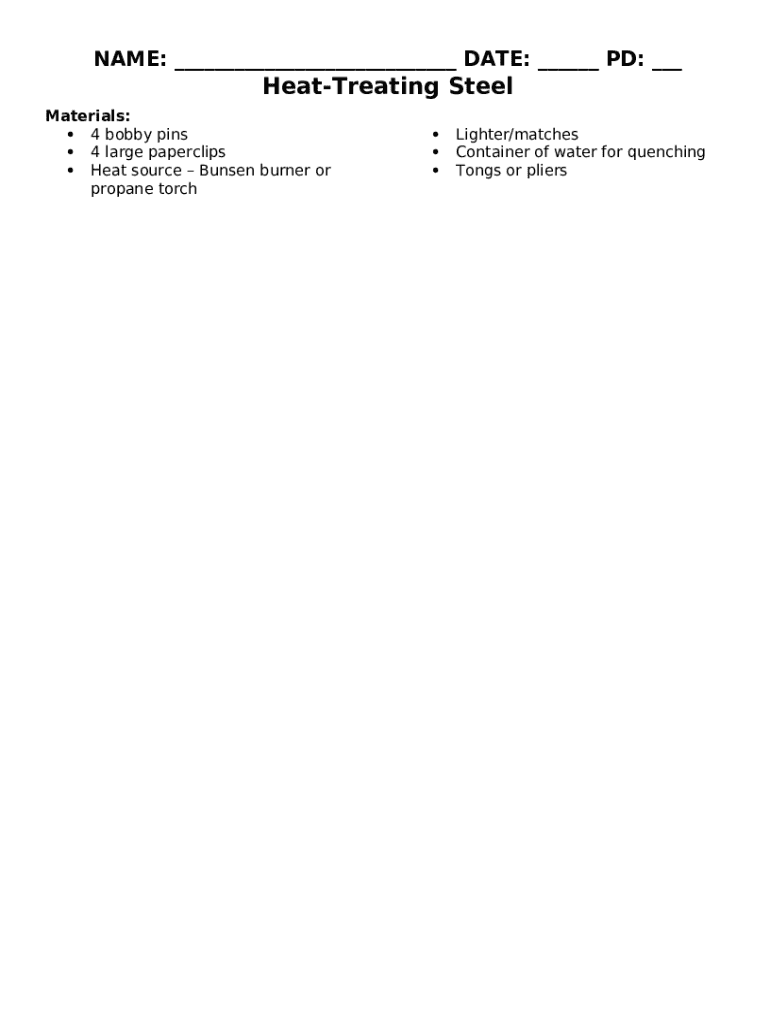

Heat Treating Steel Problem Form: A Comprehensive Guide

Understanding heat treating steel

Heat treatment is a controlled process used to alter the physical and sometimes chemical properties of steel. This treatment is crucial for enhancing the hardness, strength, toughness, and ductility of the material. It involves heating steel to a specified temperature and then cooling it down at a controlled rate. The importance of heat treatment in steel production cannot be overstated, as it directly affects the performance and longevity of steel products across various industries.

Common applications of heat-treated steel include tools, automotive components, and structural applications, where strength and durability are paramount. The treatments can involve processes such as annealing, normalizing, quenching, and tempering, each designed to achieve specific properties tailored to end-use requirements.

Challenges faced in heat treating steel

Despite its advantages, the heat treating process is not without its challenges. Manufacturers often encounter several issues that can compromise the integrity of the steel. Common problems include:

Inconsistency in steel properties: Variability in the final product can occur due to uneven heating or cooling.

Distortion and warping issues: Changes in temperature can cause the steel to warp, affecting its usability.

Surface cracking: Rapid cooling can lead to stress concentrations, resulting in surface fractures.

Incomplete hardening: Insufficient heating time or incorrect cooling methodologies may fail to achieve the desired hardness.

Case studies illustrate these common problems vividly; one case involved a batch of steel that experienced consistent warping during the quenching phase, rendering it unsuitable for its intended application in aerospace engineering. Troubleshooting such issues is vital for maintaining high-quality standards in heat-treated products.

Key factors affecting heat treatment results

Several key factors influence the outcomes of heat treatment processes. First, the composition of steel alloys plays a pivotal role in determining how steel reacts to different heat treatment techniques. Alloys can be classified into three categories: eutectoid, hypoeutectoid, and hypereutectoid, each with unique thermal characteristics.

The effects of time and temperature are critical as well. Each heat treatment process requires precise temperature control for designated durations to achieve desired transformations. Moreover, the cooling rate following heating significantly impacts the resulting microstructure and mechanical properties. Notably, furnace types, such as batch, box-type, and salt bath furnaces, also contribute to the quality of the heat treatment. Accurate monitoring and control of these variables are essential for optimizing results.

Types of heat treatments and their specific issues

Various heat treatment methods each carry their own unique set of challenges. An overview includes:

Annealing and common problems

Annealing is defined as a process aimed at reducing hardness and increasing ductility. However, issues such as improper temperature control can lead to incomplete annealing or over-annealing, adversely affecting material properties.

Normalizing

Normalizing improves microstructure and mechanical properties but may result in grain growth if the temperature is too high or maintained for too long.

Quenching techniques

Quenching involves rapid cooling to increase hardness. Issues like quenching defects occur when there’s uneven cooling, potentially leading to cracking or warping.

Tempering

The purpose of tempering is to relieve stresses and reduce brittleness. However, insufficient tempering can leave steel brittle, negating the benefits of the hardening process.

Lastly, decarburization, or loss of carbon from the surface layer, can weaken steel, particularly in cases where temperatures are not properly controlled.

Innovative solutions for heat treating problems

To combat heat treating challenges, companies are increasingly adopting innovative solutions. Advanced monitoring techniques, including real-time temperature tracking and process analytics, enhance treatment precision, thus minimizing inconsistencies.

Automation in heat treatment further optimizes the process. Automated furnaces can ensure consistent temperature profiles and timed cooling, leading to more reliable steel characteristics. Material science advancements also play a crucial role in developing alloys that better withstand heat processes, thereby reducing defects.

Selective heat treating approaches apply specific treatments to designated areas, catering to tailored performance needs without compromising overall integrity.

Interactive tools for problem identification and solutions

Utilizing tools such as a heat treating steel problem form can significantly enhance problem-solving approaches. A user-friendly problem form available on pdfFiller provides features for identifying heat treating issues effectively. This includes sections to document the specific problem, material specifications, and treatment conditions.

Filling out the problem form involves clearly articulating the issues, the treatment process undertaken, and the expected outcomes. Utilizing pdfFiller for collaboration, users can share the documents for team discussions, ensuring that multiple perspectives contribute to diagnosis and corrective actions.

Documenting the heat treatment phenomena allows teams to refer back to previous projects, leading to a more refined approach each time. The eSigning and sharing options enhance management by creating a hassle-free review process.

Best practices for successful heat treatment

Implementing best practices is essential for achieving successful heat treatment results. Start by creating a comprehensive heat treatment plan, which includes well-defined Standard Operating Procedures (SOPs). Maintaining thorough documentation and record-keeping practices ensures consistency and quality control across various treatment batches.

Training your team on heat treatment protocols is equally important. Continuous learning opportunities can bolster their understanding of the processes, thereby reducing errors and improving product outcomes. Regular workshops or training sessions can cultivate a culture of excellence within the team.

Engaging with our community

We encourage all stakeholders involved in heat treating steel to engage in discussions surrounding heat treating steel problems. Share your experiences, challenges, and solutions to facilitate knowledge exchange and collaborative problem-solving.

We welcome success stories from users who have positively transformed their heat treating processes, as these narratives can inspire others facing similar challenges. Engaging with experts can also provide valuable insights into innovative practices worth considering.

Utilizing pdfFiller for document management

pdfFiller stands out by offering seamless PDF editing, eSigning capabilities, and collaborative document management solutions that directly address the needs surrounding heat treating steel problem form management. Its interface allows users to edit forms easily, ensuring that both accuracy and clarity at every stage of documentation is maintained.

The platform’s collaborative tools improve the document sharing experience, making it easier to manage multiple revisions and feedback from team members. This leads to more refined documentation that can help in problem identification and resolution, fostering a culture of continuous improvement throughout the organization.