20lower lifting block procurement: A comprehensive guide

Understanding the lifting block

Lifting blocks are devices used to lift heavy loads in various industrial applications. They are especially integral to operations involving cranes, hoists, and other lifting machinery. By using pulleys and cables, lifting blocks can efficiently reduce the amount of physical force required to move an object vertically.

The importance of lifting blocks in industrial settings cannot be overstated. They enhance safety by ensuring that loads are raised and lowered with precision, reducing the risk of accidents. Additionally, the efficient design of lifting blocks helps streamline workflows in construction, shipping, and manufacturing industries.

Different types of lifting blocks cater to varied needs, including manual blocks, electric blocks, and pneumatic blocks. Each type presents unique advantages, making it crucial for buyers to understand the specific requirements of their operations before making a procurement decision.

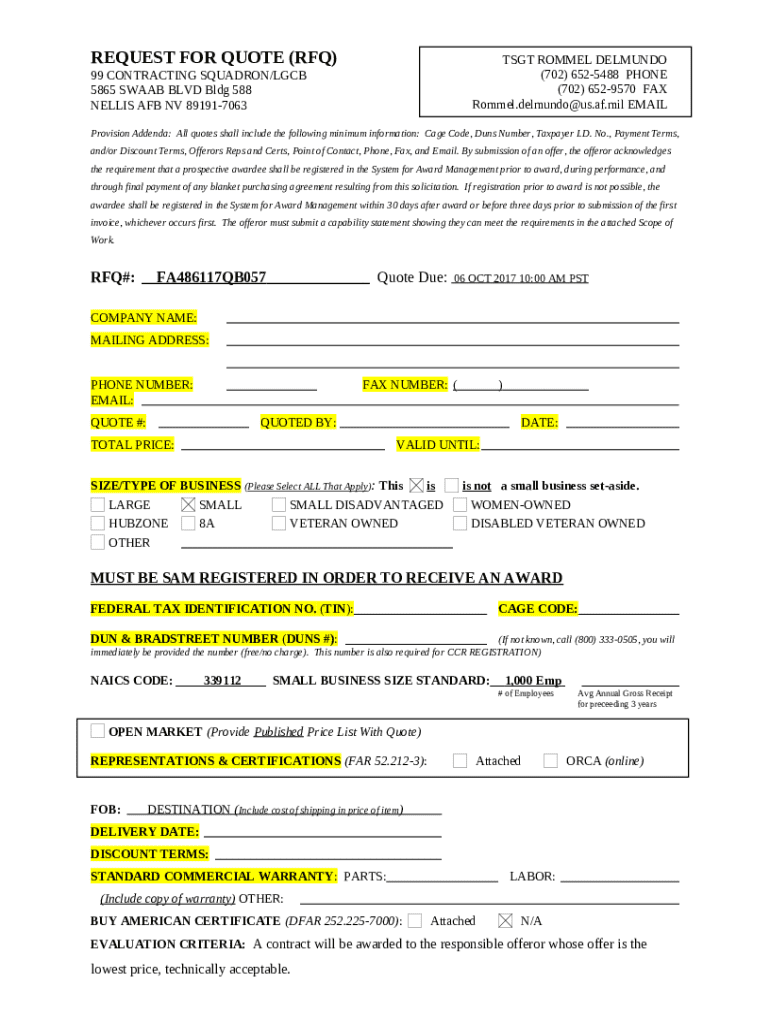

The procurement process

Acquiring lifting blocks involves a structured procurement process which includes identifying requirements, researching suppliers, and finalizing contracts. A strategic approach to procurement can lead to improved outcomes, including cost savings and enhanced safety.

When considering lifting block procurement, several key factors should guide your decision-making process.

Quality and safety standards: Ensure the lifting blocks meet relevant safety certifications and quality guarantees.

Supplier reliability and reputation: Investigate potential suppliers' track records in delivering high-quality products and customer service.

Cost analysis and budgeting: Create a budget and evaluate the total cost of ownership, including maintenance and operation.

The steps in the procurement process provide a framework for making informed purchasing decisions. It starts with clearly identifying requirements, moving to comprehensive supplier research, pricing requests, and ultimately selecting a supplier.

Navigating suppliers and marketplaces

Understanding the supplier landscape for lifting blocks can significantly impact your procurement strategy. Key players in the market vary widely, with options for domestic and international suppliers. Additionally, the market comprises specialty suppliers that focus solely on lifting devices and general suppliers that offer a broader range of industrial equipment.

Using online marketplaces has become a popular method for procuring lifting blocks. While digital procurement offers convenience and a wide variety of options, it's essential to weigh the pros and cons.

Pros: Access to extensive vendor lists, competitive pricing, and ease of comparison.

Cons: Potential risk of encountering unreliable suppliers and challenges in verifying quality.

When engaging in online procurement, ensuring security and trustworthiness in your transactions is paramount, particularly when dealing with larger amounts and essential equipment.

Evaluating lifting block specifications

Before placing an order, a solid understanding of the technical specifications associated with lifting blocks is crucial. These specifications dictate not only the suitability of a lifting block for your specific application but also its safety and performance.

Key specifications to consider include:

Load capacity: The maximum load a lifting block can safely handle.

Size and dimensions: Consider height, width, and length to ensure compatibility with existing equipment.

Material considerations: The material from which the block is made can influence durability and safety under stress.

Adhering to industry standards is equally important; be sure the lifting blocks you consider comply with applicable regulations and are certified for safe operations within your specific sector.

Making the purchase

Finalizing your lifting block procurement requires careful attention to the purchasing process. Key steps that lead to successful orders include negotiating terms and conditions with suppliers, discussing payment methods, and planning for shipping or delivery.

Strategic negotiation can often yield better pricing, warranty terms, and even ensured delivery schedules, which are pivotal in maintaining timeline efficiency.

Payment methods and terms: Confirm options for payment, such as credit terms or upfront payments.

Shipping and delivery considerations: Understand when and how the lifting blocks will arrive to plan accordingly.

Set realistic expectations for delivery, and follow up with your supplier promptly to track your order and handle any unforeseen issues.

After-purchase actions and support

Once the lifting block is delivered, conducting a thorough inspection is critical. Check for any signs of damage or defects to ensure that the product meets your expectations and specifications. Proper installation comes next, and adherence to manufacturer guidelines is vital for safe operations.

Maintenance is another focal point. Regularly servicing and maintaining your lifting blocks can extend their lifespan and ensure they perform optimally.

Routine inspections for wear and tear.

Proper lubrication and care as per the manufacturer's recommendations.

Timely repairs or replacements to prevent failure.

If issues arise, knowing when and how to contact your supplier for support is crucial. Establishing a reliable line of communication enhances operational continuity.

Utilizing pdfFiller for document management

Managing procurement documents is an essential, yet often overlooked part of the procurement process. pdfFiller streamlines this aspect effectively, offering users a comprehensive platform to manage their documents with ease.

The benefits of using pdfFiller in your lifting block procurement include:

Editing and signing procurement documents safely from any location.

Collaborative features ensuring team members can engage throughout the procurement process.

Cloud-based management for easy access and transaction tracking.

Integrating pdfFiller can enhance the efficiency of document management when filling out purchase orders, managing contracts, or maintaining records of transactions. This ensures your procurement process is organized and traceable.

Best practices in lifting block procurement

Building long-term supplier relationships is a best practice that can lead to enhanced collaboration and better service. Creating strategic partnerships with suppliers often yields rewards such as priority service and favorable pricing.

Periodic review and reevaluation of suppliers should also become part of your protocol, allowing you to assess performance and make adjustments as needed.

Regular communication to address any service or product issues.

Incorporating supplier feedback to improve product selection.

Adapting to innovations and industry changes to stay competitive.

Common challenges in procurement and their solutions

The procurement landscape can present various challenges, from supplier reliability to budget constraints. Identifying pain points early in the process allows for proactive management of these issues.

Adopting e-sourcing tools can provide greater visibility and enhance decision-making, making procurement smoother and more efficient.

Utilizing digital tools to compare multiple quotes easily.

Tracking supplier performance with analytics.

Leveraging cloud technologies for better collaboration.

Future trends in lifting block procurement

Innovation continues to reshape the procurement process. Companies are increasingly adopting technologies such as AI and machine learning to optimize procurement workflows. As the market evolves, those who can adapt to these changes will likely gain a significant competitive advantage.

Anticipated shifts in consumer needs may lead to tailored lifting block solutions that cater to specific industrial requirements, reflecting a broader trend of customization across all sectors.

Enhancing efficiency in documentation and communication

Accurate documentation is the backbone of effective procurement processes. Utilizing tools that facilitate documentation and communication can streamline operations, ensuring clarity and reducing the scope for errors.

Establishing standardized communication channels with suppliers enhances transparency and accountability, further facilitating efficient procurement.

Industry case studies

Examining successful lifting block procurement in various industries can offer invaluable insights. Case studies reveal the strategic choices made by companies, highlighting best practices and potential pitfalls.

For instance, a construction company may have streamlined its procurement process using a digital solution like pdfFiller, enhancing efficiency and reducing turnaround time significantly. These real experiences can inform future strategies and improve decision-making.