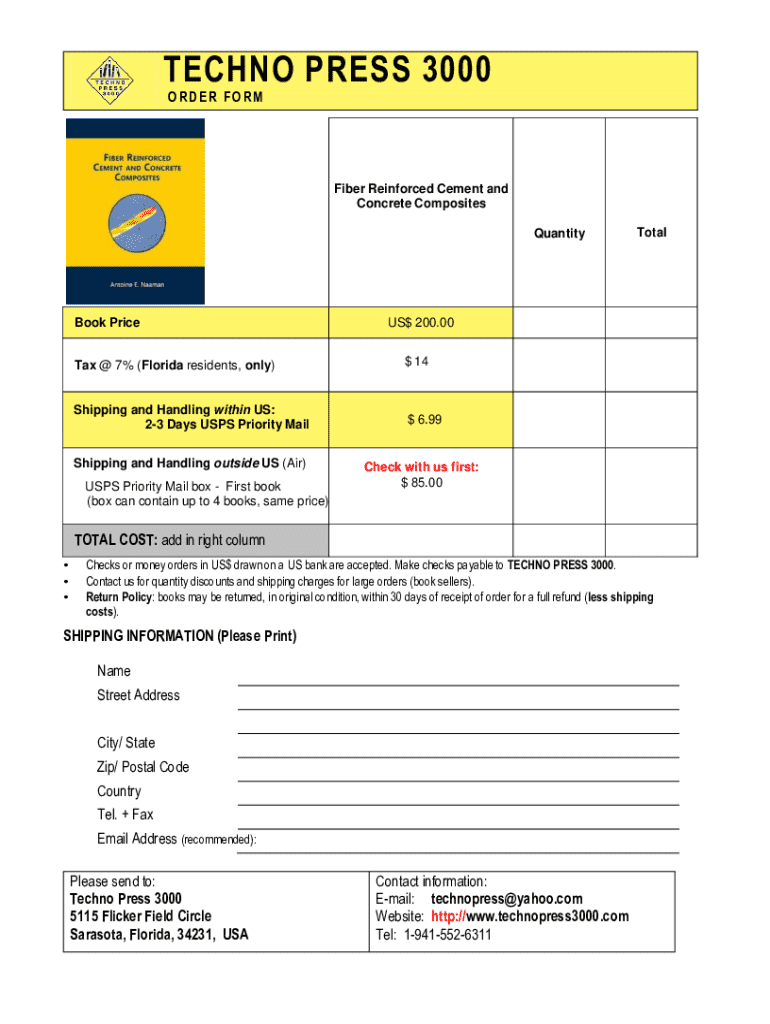

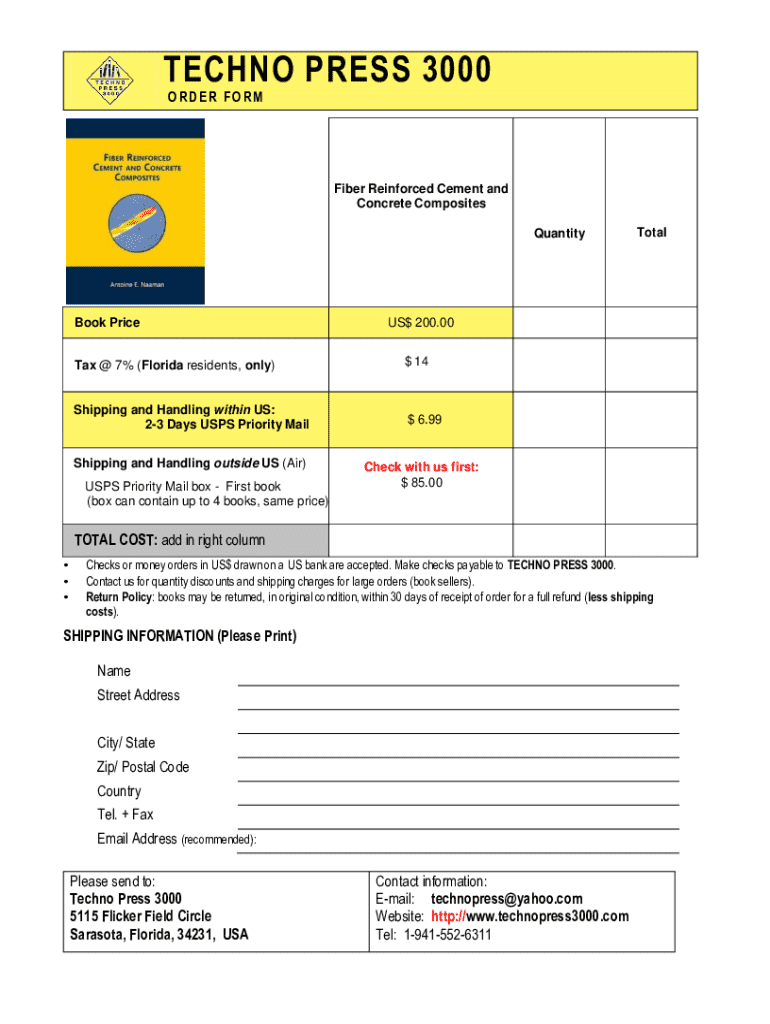

Get the free Fiber Reinforced Cement and

Get, Create, Make and Sign fiber reinforced cement and

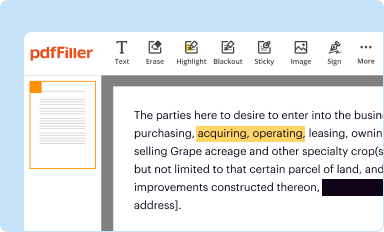

How to edit fiber reinforced cement and online

Uncompromising security for your PDF editing and eSignature needs

How to fill out fiber reinforced cement and

How to fill out fiber reinforced cement and

Who needs fiber reinforced cement and?

Fiber reinforced cement and form: A comprehensive guide

Understanding fiber reinforced cement

Fiber reinforced cement (FRC) is a composite material that integrates fibers into the cement matrix to enhance various performance characteristics, such as durability and tensile strength. The primary components of FRC include traditional cement, fine aggregates, water, and the reinforcing fibers, which can be made from steel, glass, synthetic materials, or natural fibers.

These fibers play a crucial role in mitigating issues commonly faced in conventional cement, such as cracking and shrinkage. By improving the post-cracking performance, FRC ensures that structures remain functional even under significant stress or environmental conditions. Additionally, the type of fiber used greatly influences the mechanical properties and applications of the cured cement.

Applications of fiber reinforced cement

Fiber reinforced cement is increasingly employed across various construction and engineering sectors. A common use case for FRC includes pavements, where enhanced durability is needed to withstand traffic loads. Precast panels, which require both structural integrity and aesthetic appeal, also benefit significantly from the inclusion of fibers.

Moreover, industrial flooring systems that see heavy foot or machinery traffic often utilize FRC for its superior wear resistance. Specialized applications include seismic retrofitting of existing structures, where flexibility and tensile strength are paramount. Architecturally, FRC offers the ability to create lightweight structures while maintaining high strength, contributing to innovative designs.

Benefits of using fiber reinforced cement forms

Utilizing fiber reinforced cement forms brings numerous advantages to any construction project. One of the most significant benefits is the increased structural integrity and durability it provides. The addition of fibers reduces the susceptibility of the material to cracking and shrinkage, ensuring a longer lifespan of structures.

In terms of cost efficiency, FRC can lead to long-term savings. Fewer repairs and maintenance needs translate to lower lifecycle costs for infrastructure. Additionally, the integration of FRC supports sustainable building practices, as its enhanced durability allows for reduced material use in construction without sacrificing quality.

Key considerations when working with fiber reinforced cement

When embarking on projects involving fiber reinforced cement, selecting the appropriate materials is fundamental. Factors such as the type of fiber, the grade of cement, and any necessary additives directly influence the performance and application of the final product. For instance, choosing high-quality steel fibers for heavy-load environments will yield different results than using synthetic fibers aimed at flexible installations.

It's also essential to consider the design flexibility FRC offers. Architects and engineers can customize mixtures for various applications, allowing for innovative designs that meet the specific demands of each project. Additionally, proper mixing techniques are crucial to achieving optimal consistency, ensuring uniform distribution of fibers throughout the mix.

Step-by-step guide to creating fiber reinforced cement forms

Creating fiber reinforced cement forms involves several key steps to ensure successful implementation. First, preparing the work site is paramount — conducting a site evaluation helps identify any underlying issues that could affect the curing or performance of the cement.

Next, the mixing process should be approached with care. Fusion of the fibers with the cement mix must be thorough to integrate them fully, ensuring they provide maximum reinforcement. Pouring the mixture into forms is the next step, where attention to detail is required to avoid air pockets and ensure even settling. Subsequently, curing techniques should be applied to enhance the final strength and durability of the cement.

Finally, the finishing touches allow for aesthetic considerations, transforming a practical element into a visually pleasing aspect of construction. Techniques may involve smoothing the surface or applying a protective coating to enhance longevity.

Maintenance and upkeep of fiber reinforced cement structures

Routine maintenance of fiber reinforced cement structures is crucial to prolonging their lifespan and integrity. Regular inspection procedures should focus on monitoring key areas for signs of wear, including surface cracking and significant changes in structural stability. These preventative measures can help avert more extensive and costly repairs.

For any minor damages observed, quick repair methods can be employed. Addressing cracks with appropriate sealing compounds and ensuring proper application will rectify the issue promptly. Additionally, implementing long-term care strategies, such as periodic cleanings and surface treatments, will contribute to preserving the integrity of the cement structure over time.

Frequently asked questions about fiber reinforced cement

As fiber reinforced cement becomes more commonplace in construction, several common misconceptions arise. One prevalent myth is that FRC is exclusively used for high-stress applications. In reality, its versatility means it can also enhance aesthetic applications with lightweight designs. Another misconception is that FRC is far more expensive than traditional cement mixtures, which neglects the long-term savings in maintenance and repairs that FRC structures can provide.

Technical queries often focus on the performance, such as the impact of different fibers on overall strength. Each type of fiber offers unique benefits, from the rigidity of steel fibers to the flexibility of synthetic options, making it essential to choose the right material based on the anticipated application.

Innovations and future trends in fiber reinforced cement

Innovations in fiber reinforced cement are driven by advancements in material science, which have begun making significant impacts on the performance of FRC. Manufacturers are experimenting with a range of new fibers, including advanced composites that might offer the properties of several materials combined, leading to superior performance in various environmental conditions.

Sustainable development approaches are also paving the way for eco-friendly cement formulations, which reduce the carbon footprint associated with traditional cement production. Research into alternative binding materials and the use of recycled aggregates indicates a promising future for FRC that aligns with growing environmental expectations.

Interactive tools and resources

For those looking to delve deeper into fiber reinforced cement projects, there are interactive tools and resources available to streamline the planning process. Document templates can assist in organizing project requirements, while online calculators help estimate material quantities and costs efficiently. These tools are essential for effective project management in fast-paced construction environments.

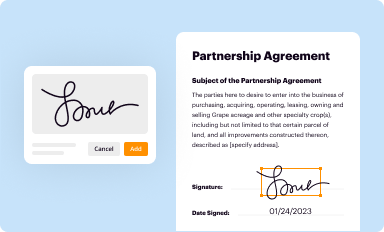

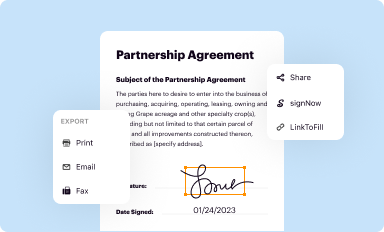

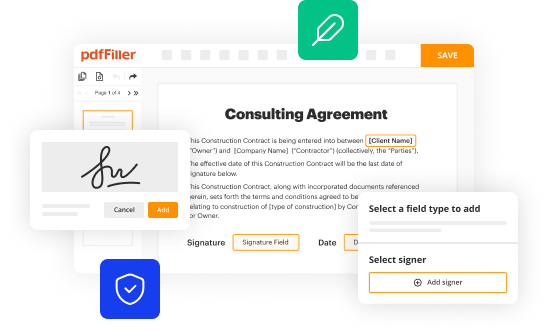

Additionally, pdfFiller offers collaborative features that can enhance teamwork, enabling individuals and teams to create, edit, sign, and manage documents relating to fiber reinforced cement projects. By utilizing a cloud-based platform, users can access and modify their documents from anywhere, ideally suited to modern construction workflows.

Case studies: successful implementations of fiber reinforced cement

Successful implementations of fiber reinforced cement span a variety of sectors, highlighting the versatility of this material. In residential projects, homes have been built using FRC for both structural and aesthetic elements, showcasing unique designs that stood resilient against weathering. The use of FRC in commercial structures has facilitated the construction of retail spaces that prioritize both functionality and artistic expression.

Civic infrastructure developments also leverage FRC, with examples of pavements and public buildings built to not only withstand heavy usage but also provide long-lasting durability that benefits the community. These case studies vividly demonstrate the importance of fiber reinforced cement in modern construction.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Can I sign the fiber reinforced cement and electronically in Chrome?

How can I edit fiber reinforced cement and on a smartphone?

How do I complete fiber reinforced cement and on an Android device?

What is fiber reinforced cement?

Who is required to file fiber reinforced cement?

How to fill out fiber reinforced cement?

What is the purpose of fiber reinforced cement?

What information must be reported on fiber reinforced cement?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.