Get the free Pump Station On-Call Maintenance and Repair Millwright ...

Get, Create, Make and Sign pump station on-call maintenance

Editing pump station on-call maintenance online

Uncompromising security for your PDF editing and eSignature needs

How to fill out pump station on-call maintenance

How to fill out pump station on-call maintenance

Who needs pump station on-call maintenance?

Comprehensive Guide to the Pump Station On-Call Maintenance Form

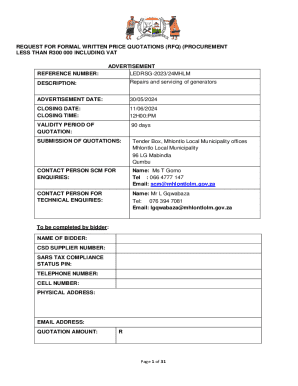

Overview of the pump station on-call maintenance form

The pump station on-call maintenance form is a critical document utilized in the management and maintenance of pump stations. Its primary purpose is to facilitate effective communication and documentation of maintenance activities, ensuring that issues are promptly addressed. By utilizing this form, maintenance teams can track the status and efficiency of pump operations, ultimately contributing to the longevity and reliability of the pumping systems.

The importance of on-call maintenance for pump stations cannot be overstated. Having a structured maintenance form helps teams quickly identify problems, making it easier to respond to emergencies or malfunctions. Furthermore, maintaining detailed records enhances accountability and aids in compliance with industry regulations and safety standards.

pdfFiller enhances the functionality of the pump station on-call maintenance form with its cloud-based document management system. This technology facilitates easy editing, eSigning, and collaboration, ensuring that maintenance teams have access to the most up-to-date information from anywhere.

Key features of the pump station on-call maintenance form

The pump station on-call maintenance form is equipped with several interactive elements designed to streamline the documentation process. Editable fields allow users to customize the form according to specific maintenance needs, making the documentation process efficient. Moreover, self-signing options expedite the approval process, ensuring that necessary authorizations can be obtained quickly.

Collaborative tools enable teams to work together effectively. Sharing capabilities mean that team members can easily access and fill out the form from different locations. Real-time editing features allow multiple personnel to contribute simultaneously, significantly reducing the time taken to complete maintenance logs.

One of the most significant advantages of the pump station on-call maintenance form is its accessibility across devices. Whether on a smartphone, tablet, or desktop, users can access the document, ensuring continuity in maintenance operations regardless of location.

Step-by-step guide to filling out the maintenance form

Filling out the pump station on-call maintenance form is a straightforward process. Start by preparing the basic information, which includes key details about the pumps such as type, capacity, and model. Ensure that you include contact information for all on-call personnel, as this is crucial for timely communication during maintenance activities.

Next, focus on the detailed sections of the form. The pump status logs should be filled out with accurate observations and issues encountered. It's essential to record the frequency of updates, as regular documentation can pinpoint patterns in pump performance over time.

Within the emergency response procedures section, outline guidelines for action steps to take in various scenarios and list important contacts. Keep this section updated to reflect any changes in personnel or procedures.

A collaborative review process allows all team members to validate the information before it is finalized. It's wise to keep an eye out for common mistakes, such as omitting crucial details or using outdated contact information.

Editing and customizing the on-call maintenance form

Editing the pump station on-call maintenance form is made easy through an intuitive interface. Utilize various tools and techniques for effective document editing, from adding comments and annotations that provide context to certain entries to incorporating company branding elements to maintain a consistent professional appearance.

Personalizing the form for different scenarios can streamline the maintenance process. Develop templates tailored to various types of pump systems, ensuring that every relevant detail is captured for each specific case.

eSigning the maintenance form

The use of eSignatures in maintenance forms offers numerous benefits. It enhances compliance and reliability by creating a clear electronic trail of approvals and modifications. Moreover, the process saves valuable time that could be lost in traditional signing methods.

To eSign the maintenance form, follow these simple steps: Locate the eSignature feature within the form, follow the prompts to sign electronically, and send the completed document. You can also track signed documents to ensure that they have been received by the intended recipients.

Managing and storing the pump station maintenance documents

Best practices for document organization can have a profound impact on maintenance efficiency. Create folders and tagging systems that allow easy retrieval of necessary documents. With the pump station on-call maintenance form, you can categorize documents based on inspection dates or specific issues encountered.

Cloud storage provides superior benefits for on-call maintenance documentation. The implementation of robust security protocols ensures that sensitive data is protected while allowing for access from multiple locations and devices. This flexibility enhances team responsiveness and collaboration, crucial for addressing maintenance needs swiftly.

Additional considerations for pump station maintenance

Regular inspection protocols should be established to maintain operational efficiency and safety at pump stations. Suggested frequencies for checks might include daily visual inspections and weekly performance evaluations. Key areas to consistently monitor include pump efficiency, leak detection, and equipment wear.

Adhering to compliance regulations and industry standards is vital for the safety and integrity of pump operations. Regular training for on-call personnel is essential to ensure they understand best practices and can effectively assess compliance needs.

Lastly, assessing the effectiveness of on-call maintenance practices through regular reviews can help identify areas for improvement. Gathering feedback from team members can offer insights into how well the processes are functioning.

The role of technology in pump station maintenance

Technology plays a transformative role in enhancing maintenance efficiency at pump stations. Innovative tools such as IoT sensors can monitor pump performance in real-time, providing data that can be analyzed for predictive maintenance.

Future trends in pump station management likely include greater automation and the integration of AI solutions. These advancements can lead to improved predictive analysis, thus enhancing response times and reducing the chances of unexpected failures.

FAQs on pump station on-call maintenance

Common queries related to the pump station on-call maintenance form often involve issues concerning usability and access. For instance, users may ask how they can edit the form on mobile devices or what best practices exist for sharing the form within a team.

It's essential to address concerns about accessibility since the ideal solution should provide an inclusive platform that accommodates various user levels. Ensuring the form is straightforward and intuitive can mitigate many usability issues.

Success stories and case studies

Real-life scenarios utilizing the pump station on-call maintenance form demonstrate its effectiveness. For example, a municipal water treatment facility implemented the form and reported a 30% decrease in downtime due to rapid response to recorded issues.

Another case study involved a manufacturing plant that customized the form to track preventative maintenance schedules, leading to improved operational efficiency across their pumping systems. These examples underscore the benefits of adopting structured documentation processes.

Interactive tools and resources

Accessing additional maintenance templates can significantly enhance the effectiveness of the pump station on-call maintenance form. Various online resources can provide users with templates specific to different types of pump systems, aiding in customization.

Moreover, seamless integration with other document management tools allows maintenance teams to create a comprehensive suite of digital forms, ensuring that all aspects of maintenance operations are covered.

Final touch

In conclusion, the transition to using a cloud-based document management solution like pdfFiller for the pump station on-call maintenance form can dramatically enhance maintenance operations. The ability to edit, eSign, and manage documents effectively ensures that maintenance teams can focus on their primary objectives — safeguarding pump station functionality and reliability.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I modify pump station on-call maintenance without leaving Google Drive?

Can I create an electronic signature for the pump station on-call maintenance in Chrome?

How do I fill out pump station on-call maintenance using my mobile device?

What is pump station on-call maintenance?

Who is required to file pump station on-call maintenance?

How to fill out pump station on-call maintenance?

What is the purpose of pump station on-call maintenance?

What information must be reported on pump station on-call maintenance?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.