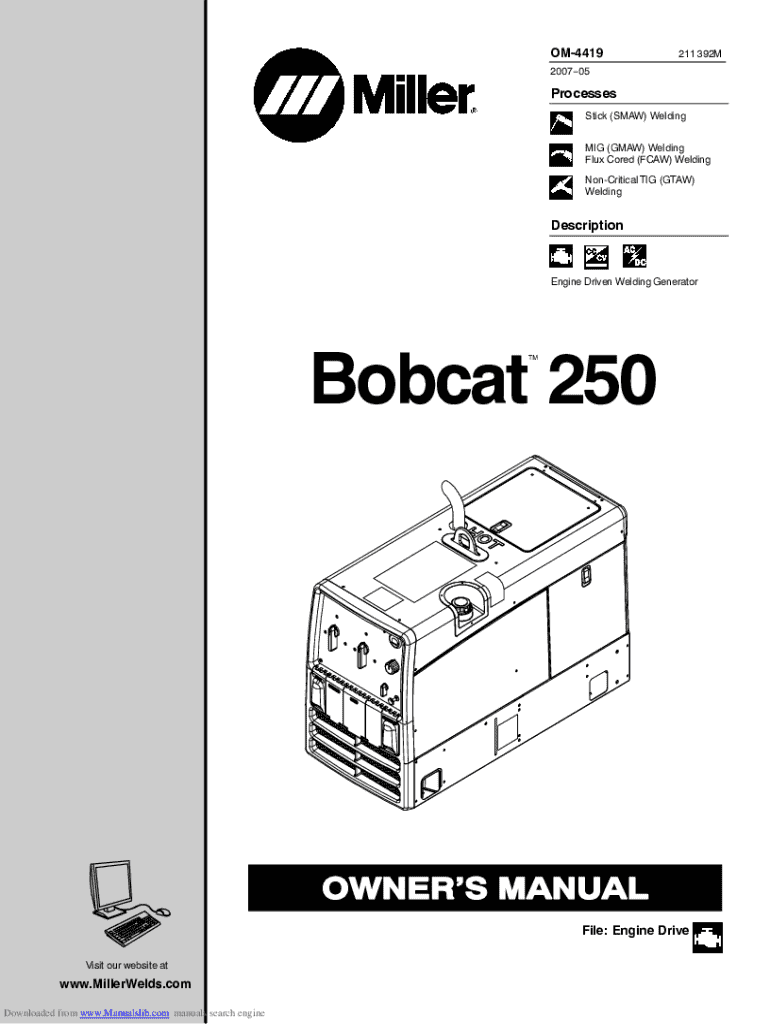

Get the free MIG & Flux Process #migwelding #fcaw #gmaw #welding ...

Get, Create, Make and Sign mig amp flux process

Editing mig amp flux process online

Uncompromising security for your PDF editing and eSignature needs

How to fill out mig amp flux process

How to fill out mig amp flux process

Who needs mig amp flux process?

Understanding the MIG Amp Flux Process Form

Understanding the MIG Amp Flux Process Form

The MIG Amp Flux Process is a specialized welding procedure that utilizes Metal Inert Gas (MIG) techniques combined with flux-core wire. This process is particularly effective for delivering high-quality welds in various metal fabrication settings, thanks to its adaptability and efficiency. The MIG Amp Flux Process Form is the document that captures critical information about the specific parameters of this welding technique, ensuring that welders and engineers maintain quality and consistency throughout their projects.

The importance of the MIG Amp Flux Process in welding cannot be overstated. This process not only enhances the structural integrity of welded joints but also optimizes workflow with its speed and versatility. Proper documentation through the MIG Amp Flux Process Form enables compliance with safety regulations, quality control standards, and efficient project management. By having the right documentation in place, welding teams ensure that they are prepared for inspections, audits, and project evaluations.

Preparing for the MIG Amp Flux Process

Before diving into the mechanics of filling out the MIG Amp Flux Process Form, it’s crucial to gather the necessary documentation and forms required for MIG welding. Essential forms related to MIG welding include not just the process form itself, but also safety compliance documents, materials data sheets, and quality assurance checklists. Having the correct versions of these documents is paramount, as outdated or incorrect forms can lead to discrepancies in the welding process.

The MIG Amp Flux Process Form plays a significant role in quality control. It captures vital details such as welding parameters, rod specifications, and equipment settings. Ensuring that this form is filled out accurately is essential for compliance with established safety and operational standards. Well-maintained documentation aids not only in personal accountability but also in team coordination, particularly on larger projects where multiple welders may rely on shared data.

Key components of the MIG Amp Flux Process Form

The MIG Amp Flux Process Form comprises essential fields that serve specific purposes. Key components include voltage settings, amperage factors, and flux type specifications. For example, voltage settings determine the heat applied during welding, while amperage factors relate to the electrical current used. The flux type affects the quality of the weld bead and protection against oxidation. Each of these fields is integral to achieving a successful weld.

When annotating the form, clarity is vital. Use specific, unambiguous terms while filling out technical details to avoid any misunderstandings. Ensuring accuracy in data entry is not simply a matter of form-filling; it is about comprehensively capturing the conditions under which welding occurs. This information is pivotal for troubleshooting, process evaluation, and ensuring compliance with best practices in welding.

Steps for filling out the MIG Amp Flux Process Form

Before completing the MIG Amp Flux Process Form, review project specifications and gather necessary tools and data. Preliminary steps may include checking the welding machine settings, confirming that materials match specifications, and ensuring that safety protocols are in place. A thorough preliminary review can save significant time and resources during the actual welding process.

The following step-by-step instructions will guide you in accurately filling out the form: 1. Confirm equipment settings, making sure that the MIG welder is correctly set up according to the anticipated welding parameters. 2. Record material specifications carefully, detailing the type and grade of materials being used. 3. Lastly, document all welding parameters, including voltage, amperage, and wire feed speed. Avoiding common mistakes such as misestimating parameters or neglecting to cross-check details is crucial. Missing information can lead to operational inefficiencies and quality issues.

Editing & managing the MIG Amp Flux Process Form

Utilizing tools like pdfFiller can significantly enhance document management when dealing with the MIG Amp Flux Process Form. Online platforms allow users to edit PDFs, fill out forms, and add comments in real-time, which is particularly useful for collaborative work environments. By employing pdfFiller, teams can access the form from any location, facilitating communication and coordination among members.

Tracking changes and establishing a review process is critical in maintaining the integrity of the MIG Amp Flux Process Form. Utilizing version control ensures that all members are working off the latest document, reducing the risk of errors stemming from outdated information. Additionally, using comment tools can promote effective communication, allowing team members to provide feedback or raise questions directly on the form.

Signatures and approvals

Understanding the need for eSigning is essential in the context of the MIG Amp Flux Process Form. Legally binding documents require signatures to validate the information contained within them. Utilizing digital signatures streamlines approval workflows because it eliminates the need for physical workflows, allowing for quicker project timelines without sacrificing compliance or accountability.

When setting up signature fields on the form, it’s important to follow best practices to include multiple signatories when needed. Designate clear fields for each required signature, making them user-friendly and accessible. This attention to detail not only enhances workflow efficiency but also reassures team members that their contributions are recognized and validated within the project's scope.

Managing your MIG Amp Flux Process Forms

Once the MIG Amp Flux Process Form is completed, organizing documents becomes a priority. Strategies for digital filing might include using clear file naming conventions, categorizing forms by project or date, and incorporating tags for easy retrieval. Employing a systematic approach to document management saves valuable time, especially when multiple forms are being handled simultaneously.

In addition, sharing and storing forms securely is vital. Options for cloud storage like those provided by pdfFiller enhance accessibility while ensuring that documents are backed up and protected. By establishing a secure method of sharing, stakeholders can avoid breaches of privacy and maintain data protection, crucial aspects in the professional welding industry.

Troubleshooting common issues with MIG Amp Flux Process Forms

Identifying frequent problems associated with the MIG Amp Flux Process Forms is essential to maintaining workflow efficiency. Common issues include misfiled documents or errors in completed forms, which can have significant repercussions on project timelines and quality. Addressing these problems proactively can lead to quicker resolutions and minimize disruptions in the welding process.

To resolve discrepancies, begin by reviewing forms against the original project specifications and make the necessary corrections. It’s a good practice to cross-check details with team members when anomalies are found. Knowing when to consult technical support is also critical; if issues are complex or outside your expertise, don’t hesitate to reach out to the documentation platform's customer support for guidance.

Resources for further learning

For those seeking further education on the MIG Amp Flux Process and its associated documentation, access to document templates and examples can be beneficial. pdfFiller offers industry-standard templates that can simplify the form-filling process while ensuring compliance with welding regulations.

Additionally, participating in video tutorials and webinars can greatly enhance your understanding of MIG welding processes. These resources provide visual and interactive learning opportunities, making complex topics more digestible and practical for users.

Engaging with the community

Building a network is key for professionals involved in the MIG Amp Flux Process. Engaging with online forums and social media groups dedicated to welding can provide valuable insights and shared experiences. Many of these platforms allow users to exchange tips, discuss common challenges, and offer solutions to problems specific to the MIG welding community.

Moreover, networking opportunities through local welding associations or industry expos can provide face-to-face interaction, enabling professionals to connect and share knowledge. Embracing community engagement not only augments personal development but also fosters an environment of collaboration and innovation within the welding industry.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I execute mig amp flux process online?

How do I edit mig amp flux process in Chrome?

Can I sign the mig amp flux process electronically in Chrome?

What is mig amp flux process?

Who is required to file mig amp flux process?

How to fill out mig amp flux process?

What is the purpose of mig amp flux process?

What information must be reported on mig amp flux process?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.