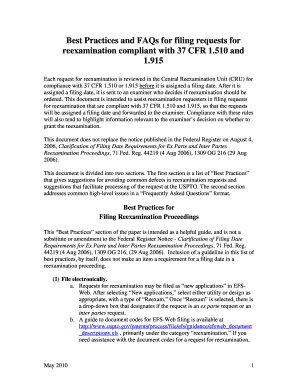

Get the free press wheel truck speader operators manual 1-800-277- ...

Get, Create, Make and Sign press wheel truck speader

How to edit press wheel truck speader online

Uncompromising security for your PDF editing and eSignature needs

How to fill out press wheel truck speader

How to fill out press wheel truck speader

Who needs press wheel truck speader?

Press Wheel Truck Spreader Form: A Comprehensive How-To Guide

Understanding the press wheel truck spreader

Press wheel truck spreaders play a vital role in agriculture and industrial applications, offering an effective solution for distributing seeds, fertilizers, and other materials evenly across land. Their design combines the robust features of a traditional truck with specialized spreader functionalities, allowing users to manage diverse materials efficiently. In modern agriculture, where precision and efficiency are paramount, these spreaders are indispensable tools that enhance yield and streamline operations.

The importance of press wheel truck spreaders extends beyond mere distribution. They help ensure that seeds are planted at the correct depth, fertilizers are applied in just the right amounts, and other materials are uniformly spread, minimizing wastage. The key features, including durable builds, efficient application methodologies, and versatility, highlight why these devices are essential across various industries.

Preparing your press wheel truck spreader

Before utilizing a press wheel truck spreader, proper preparation is crucial for optimal performance. Essential pre-usage checks and maintenance can prevent operational issues and enhance the machine's longevity. Start by inspecting tire and axle conditions, ensuring they are in good shape to support the equipment during transport and operation. Additionally, checking the hopper integrity guarantees that the spreader can hold and discharge materials effectively.

Further checks should include the metering and drive system; ensuring these components function correctly is pivotal for achieving the desired application rates. Common tools required for setup encompass a basic toolkit for repairs and calibration devices to fine-tune the spreader before use.

Completing the truck spreader form

Accurate completion of the press wheel truck spreader form is crucial to document essential details for operation and compliance. This form serves multiple purposes, including equipment tracking and ensuring operational safety. Each section has specific elements that need to be addressed, which enhances accountability and precision in use.

To fill out the form effectively, follow these step-by-step instructions. First, provide your personal information, such as name and contact details. Next, detail spreader specifications, including the model and capacity, which assists in managing the specific requirements of your spreader type. Finally, include operational guidelines, elaborating on best practices and maintenance tips to ensure longevity and reliability during use.

Utilizing interactive tools can enhance the form-filling experience. For instance, using PDF editing features makes it easy to correct errors, while collaborative options allow team members to contribute to the form, ensuring that all necessary details are captured.

Optimizing your spreader settings

Adjusting settings on your press wheel truck spreader is essential for maximizing performance across different materials. It’s vital to understand the specific requirements of what you're spreading, whether it’s fertilizers, seeds, or any other materials. Incorrect settings can lead to uneven distribution, wastage, and even crop failure in agricultural setups.

Begin by familiarizing yourself with the spreader’s settings and how they affect material throughput. For instance, varying the speed of the spreader or adjusting the opening of the metering system can optimize the distribution. Regular maintenance is equally critical; ensuring that all components function smoothly can significantly improve the machine's lifespan and effectiveness.

Troubleshooting common issues

As with any machinery, issues can occur during operation. Common problems with press wheel truck spreaders include uneven distribution and equipment jamming. Identifying these issues early can save time and resources, ensuring that operations continue smoothly.

Uneven distribution may arise from incorrect settings, obstructions in the hopper, or wear in components. Regular maintenance routines can help mitigate these problems. If your equipment jams, it's often due to material clumps or mechanical failure. Always refer to the owner's manual for specific troubleshooting steps and preventative measures to minimize downtime.

Collaborating on spreader usage

In agricultural settings, collaboration among team members operating any machinery, including press wheel truck spreaders, enhances productivity and safety. Following best practices for communication can lead to better operation insights and real-time adjustments during spreading activities.

Using PDF tools for team collaboration ensures all members are on the same page regarding adjustments made and procedures followed. Documenting changes can be accomplished effectively with tools like pdfFiller, allowing for easy version control and ensuring everyone has access to the latest instructions and modifications.

Managing compliance with regulations

Using press wheel truck spreaders requires adherence to local agricultural regulations. Understanding and managing compliance is vital for ensuring safety and maintaining operational standards. Various governing bodies often impose specific guidelines on the types of materials that can be spread and the methods used.

Keeping necessary documentation organized is essential. This involves maintaining records of the materials used, application rates, and adhering to compliance protocols. Various resources, including government websites and agricultural boards, can provide guidance on local compliance regulations.

Enhancing productivity and efficiency

Optimizing the use of your press wheel truck spreader can drastically enhance productivity. Embracing technology, such as advanced PDF filling tools for form management, simplifies documentation and ensures all necessary data is captured correctly. The efficiency of operations largely depends on accurate reporting, which can ultimately inform future decisions and strategies.

Utilizing data analytics by reviewing past spreader usage can help in refining settings for different conditions, leading to better material use and timing. Accurate reporting also contributes to effective planning, ensuring you stay ahead of scheduling needs and material availability.

Application insights and use cases

Exploring real-world applications of press wheel truck spreaders can unveil their utility across various industries. For instance, in agriculture, these spreaders are utilized to maintain proper seed spacing and fertilizer distribution. Similarly, landscaping firms employ them for even mulch coverage and sod installation, emphasizing versatility.

Case studies from different regions illustrate how users have maximized their yields and improved operational efficiency through effective spreader use. Testimonials showcase satisfaction, further validating the importance of proper form utilization and documentation, which is seamlessly facilitated through tools like pdfFiller.

Future trends in spreader technology

The evolution of technology predicts an exciting future for press wheel truck spreaders. Innovations such as GPS-guided systems and automated settings are on the horizon, propelling efficiency to new levels. Moreover, the integration of digital tools continues to streamline operations, presenting significant opportunities for enhanced accuracy and reduced waste.

As agricultural technology continues to advance, current trends indicate a shift towards data-driven decision-making, where analytics inform the optimal times and amounts for spreading materials. Collaborative frameworks for equipment management are also emerging, indicating a shift towards team-driven approaches in efficiency.

Frequently asked questions (FAQ)

Common queries about press wheel truck spreaders often revolve around their operation, maintenance, and compliance with regulations. Understanding the nuances of spreader usage can significantly contribute to successful agricultural practices and questionnaire.

For deeper insights or specific questions, users are encouraged to reach out through dedicated support channels aimed at assisting in equipment management and proper usage for peak performance.

Conclusion: Streamlining your workflows

Integrating PDF filling tools with your equipment management processes can streamline workflows and enhance productivity. With a focus on capturing all necessary details accurately through forms, it's easier to manage operations, ensure compliance, and maintain communication among team members.

Future-proofing agricultural practices with technology, especially tools like pdfFiller, ensures that you stay ahead in efficiency and operational excellence, paving the way for innovative methodologies in the agricultural landscape.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I execute press wheel truck speader online?

How do I edit press wheel truck speader in Chrome?

How do I edit press wheel truck speader straight from my smartphone?

What is press wheel truck speader?

Who is required to file press wheel truck speader?

How to fill out press wheel truck speader?

What is the purpose of press wheel truck speader?

What information must be reported on press wheel truck speader?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.