Get the free Horizontal vs. inclined impact testing: when to use each

Get, Create, Make and Sign horizontal vs inclined impact

Editing horizontal vs inclined impact online

Uncompromising security for your PDF editing and eSignature needs

How to fill out horizontal vs inclined impact

How to fill out horizontal vs inclined impact

Who needs horizontal vs inclined impact?

Horizontal vs Inclined Impact Form: Understanding the Differences and Applications

Understanding impact testing: The basics

Impact testing is a critical method used to evaluate the durability and resilience of packaging materials under sudden forces that could occur during transportation and handling. This method assesses how well a package can withstand drops, knocks, or vibrations. Impact testing is essential in packaging because it provides insights into potential failure modes, ensuring products reach consumers in optimal condition. The two primary methodologies for conducting impact tests are horizontal and inclined impact tests, each differing in setup and application.

Horizontal impact testing: A closer look

Horizontal impact testing involves dropping a package onto a flat surface from a predetermined height, simulating the forces experienced during transit or handling. This method is widely used across various industries, including food and beverages, pharmaceuticals, and electronics. Many packages are designed to be handled primarily in a horizontal orientation, making this test relevant for ensuring they meet the necessary durability criteria.

Key features of horizontal impact test systems include adjustable drop heights, standardized impact surfaces, and the ability to quantify impact forces. These systems facilitate accurate replicability, essential for fruitful testing. Among its numerous advantages, horizontal impact testing is recognized for its simplicity and ease of use, as well as its versatility. It can accommodate a wide range of packaging types, allowing businesses to tailor their testing approaches to specific products.

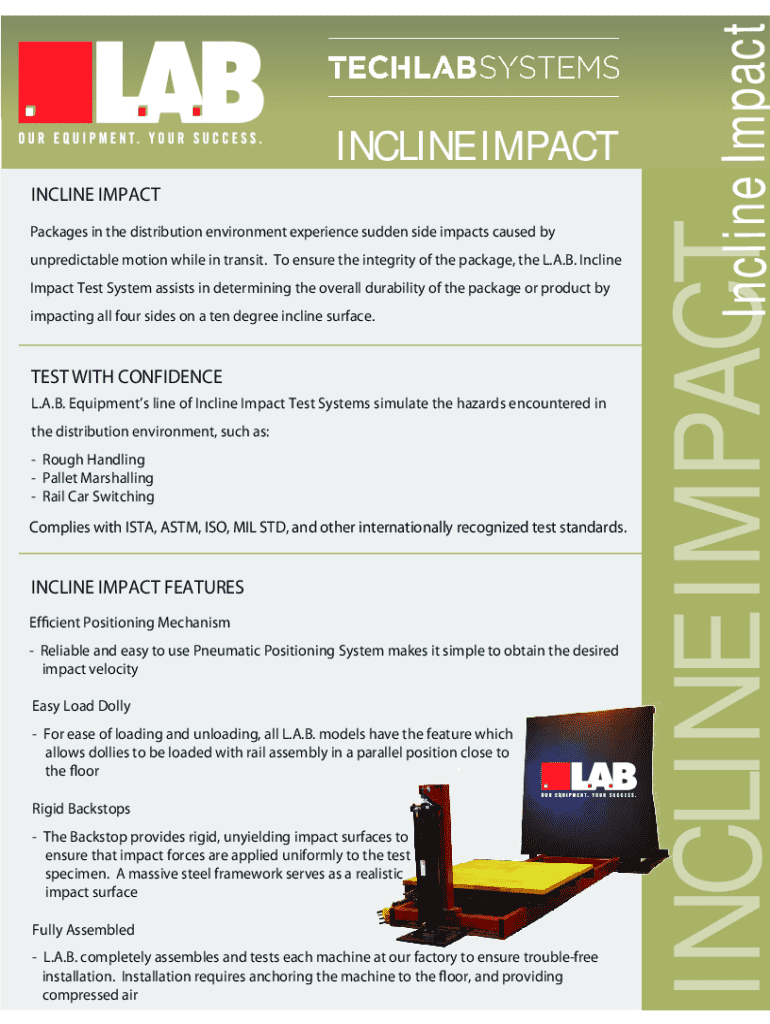

Inclined impact testing: An overview

Inclined impact testing, on the other hand, involves dropping packages onto an inclined surface. This method is particularly useful in scenarios simulating real-world conditions where products may slide or tip during transit. For example, stacked packages loaded onto a truck may experience impacts at angles, making inclined testing crucial for ensuring packets withstand such impacts successfully.

Specific applications of inclined impact testing are prevalent in the food industry, where packages might roll or tip during distribution, and in fragile items, such as glass and ceramics, that require enhanced protection from angled impacts. Inclined impact test systems are designed to replicate such handling conditions accurately, allowing for thorough evaluation. The primary advantage is their ability to simulate more realistic distribution scenarios, making the results directly applicable to real-life situations.

Comparing horizontal and inclined impact testing

When comparing horizontal and inclined impact testing, several factors come into play. The design and setup of equipment for both methods vary, with horizontal tests often requiring less complexity due to the straightforward drop mechanics. In contrast, inclined tests demand specialized setups to ensure appropriate angles and support.

Testing protocols and standards also differ. Horizontal tests are more standardized in many industries, while inclined tests may adhere to specific guidelines depending on the product type. The accuracy and precision of results can vary based on the testing conditions set for each method. Businesses must analyze the suitability of each method based on particular packaging scenarios to determine which testing approach best addresses their needs.

Selecting the right impact test method

Choosing between horizontal and inclined impact testing involves various considerations. The type of product and its packaging materials should be the first priority. For items expected to withstand horizontal impacts primarily, horizontal testing may suffice. However, for products susceptible to angled impacts, like fragile containers, inclined testing could provide better insights.

The distribution environment is another critical factor. If products are typically shipped in vertical stacking or subjected to dynamic handling, inclined testing is likely the more informative choice. Companies must also consider compliance with industry standards and regulations, which may dictate specific testing methods. Reviewing case studies relevant to the product line can further inform the decision, providing concrete examples of tested and successful products.

How to prepare for impact testing

Preparation is crucial in achieving reliable impact testing results. The first step involves carefully selecting and packaging the items to be tested, ensuring they are representative of what will be distributed. It's important to follow the specific guidelines for packaging and securing any items within the boxes so that the tests accurately reflect real-world conditions.

Setting up the testing environment also requires meticulous attention. Calibration of the impact testing equipment should be verified per manufacturer specifications and industry standards. Compliance with testing protocols is vital in gathering meaningful results. Documentation should be maintained throughout the process, from packaging specifications to testing outcomes, facilitating easy analysis post-testing.

Interpreting impact test results

Understanding the results from impact tests involves analyzing key metrics and data collected during the process. These often include force measurements, package performance ratings, and any visible structural damages post-testing. For horizontal and inclined tests, comparative analysis may uncover how each method affects test results.

Taking actionable insights from the results is paramount for improving packaging processes. If a package fails during testing, identifying specific points of failure can guide redesign efforts, enabling better protection for products in transit. Effective communication of results and findings to relevant stakeholders ensures everyone involved is aligned towards necessary improvements.

Utilizing pdfFiller for impact testing documentation

In the landscape of impact testing, documentation plays a pivotal role. pdfFiller provides tools that empower teams to create, edit, and manage impactful test forms seamlessly. With features for editing and eSigning test reports, users can ensure that all documentation adheres to compliance standards while enabling easy modifications as requirements change. The versatility of pdfFiller allows multiple team members to collaborate on developing testing reports, making it a crucial asset in the testing process.

Integrating these tools into the impact testing workflow can streamline the documentation process, reducing turnaround times and increasing accuracy in records management. With pdfFiller, users can also keep their files organized and easily retrievable, allowing for efficient review and follow-up on past tests—a vital aspect of continuous improvement.

Support and resources

For those who need assistance with their impact testing methodologies, reaching out to experts can provide valuable insights. Many professionals offer support services to help navigate the complexities of testing standards and procedures. Frequently asked questions regarding impact testing cover various topics, from basic definitions to detailed industry standards, providing a go-to resource for immediate answers.

Additional tools can enhance efficient test management, including project management software, impact calculation tools, and standardized templates for quicker documentation. Companies should continually invest in resources that keep them informed about best practices in impact testing, ensuring they adapt to emerging standards and technological advancements.

Enhancing your impact testing strategy

Impact testing is not a one-time endeavor; it requires continuous improvement based on feedback and results. Companies that actively analyze testing outcomes can detect trends and pinpoint areas needing attention or innovation in their packaging design. By enhancing packaging processes with insights gleaned from both horizontal and inclined impact tests, businesses stand to significantly boost their product integrity and reliability during transit.

Staying ahead in the field of impact testing involves adopting best practices, using advanced testing methods, and continuously educating teams on emerging standards and technologies. Implementing a culture of testing within packaging development fosters a proactive approach to quality assurance, reducing returns and increasing customer satisfaction.

Bonus section: Related posts

For further information, explore related posts on ASTM standards for impact testing, which delve into specific criteria and guidelines for various packaging sectors. Additionally, case studies on successful packaging tests provide valuable context and real-world applications of both horizontal and inclined impact testing. These readings can deepen understanding and spark insights into best practices for your organization.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I make edits in horizontal vs inclined impact without leaving Chrome?

How can I fill out horizontal vs inclined impact on an iOS device?

Can I edit horizontal vs inclined impact on an Android device?

What is horizontal vs inclined impact?

Who is required to file horizontal vs inclined impact?

How to fill out horizontal vs inclined impact?

What is the purpose of horizontal vs inclined impact?

What information must be reported on horizontal vs inclined impact?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.