Get the free Tablet Strip Packing Machine: The Complete Buying Guide ...

Get, Create, Make and Sign tablet strip packing machine

Editing tablet strip packing machine online

Uncompromising security for your PDF editing and eSignature needs

How to fill out tablet strip packing machine

How to fill out tablet strip packing machine

Who needs tablet strip packing machine?

Comprehensive Guide to Tablet Strip Packing Machine Form

Overview of tablet strip packing machines

Tablet strip packing machines are specialized equipment designed for packaging pharmaceutical tablets into strip form. They serve the primary purpose of protecting the contents from environmental factors, ensuring dosage integrity, and facilitating ease of distribution. Given the delicate nature of pharmaceutical products, these machines are crucial in preventing contamination and damage during transport.

In the pharmaceutical industry, the significance of tablet strip packing machines cannot be overstated. They not only enhance product protection but also streamline production processes, ultimately leading to improved efficiency and profitability. Various types are available, each suited for different production scales and requirements, making them versatile tools in modern manufacturing.

Key components of a tablet strip packing machine

Understanding the components of a tablet strip packing machine is essential for optimizing its use and maintenance. Key mechanical components include the feeding system, cutting system, sealing roller cavity, and printing system. The feeding system ensures efficient entry of tablets, while the cutting system accurately divides strips into defined lengths.

The sealing roller cavity is crucial for maintaining product integrity by securely sealing the packaging, and the printing system allows for easy labeling and compliance with regulatory standards. Additionally, electrical and control systems enhance machine functionality. This includes the motor system, which drives the machine operation, and sensor integration that monitors key parameters during packing.

Benefits of using a tablet strip packing machine

Employing a tablet strip packing machine significantly enhances product protection against environmental factors such as moisture and light, which can degrade the quality of tablets. Additionally, these machines play a vital role in maintaining dosage accuracy by ensuring consistent distribution of each tablet within the strip. This focus on precision helps pharmaceutical companies adhere to regulatory standards and enhance consumer trust.

The efficiency of these machines directly contributes to increased production rates, with many models capable of producing thousands of strips per hour. Furthermore, many modern tablet strip packing machines are designed with compact dimensions, making them ideal for facilities where space is at a premium. Enhanced productivity combined with effective space utilization exemplifies why these machines are essential in today's pharmaceutical landscape.

How to select the right tablet strip packing machine

Selecting the appropriate tablet strip packing machine requires careful consideration of several factors. First, production capacity requirements must be identified. This includes evaluating the volume of tablets to be packaged daily and ensuring the machine can handle those volumes efficiently without sacrificing quality.

Additionally, the type of tablets to be packed—such as coated, uncoated, or chewable—will influence the choice of machine. It is also essential to determine the desired level of automation; some manufacturers may prefer machines that require more manual intervention, while others seek fully automated solutions for maximum efficiency. Compatibility with the materials used in packaging and compliance with regulatory standards, such as those mandated by the FDA, should also be reviewed meticulously.

Operating instructions for tablet strip packing machines

Operating a tablet strip packing machine effectively necessitates familiarity with its functions and control settings. A step-by-step procedure typically begins with loading the tablets into the feeding system. Following this, operators must set the correct sealing temperatures and cutting dimensions, either through the control panel or an integrated touchscreen interface. Regular monitoring of the machine for consistency is critical during the packing process.

Common settings and adjustments may include the speed settings for the feeding and cutting systems, as well as tuning the sealing roller parameters to accommodate different tablet types. Scheduling regular maintenance checks, including lubrication of moving parts and inspection of electronic systems, will ensure optimal performance and longevity of the machine. Documenting these maintenance schedules can also help anticipate issues before they arise.

Troubleshooting common issues with tablet strip packing machines

Despite their efficiency, tablet strip packing machines can sometimes experience operational problems. Machine jamming is a frequent issue, often caused by improper tablet alignment or inadequate loading into the feeding system. Inconsistent sealing can arise from fluctuating temperature settings or worn-out sealing rollers, jeopardizing both product quality and compliance.

Product damage during packing is another critical issue that can occur due to excessive pressure during the sealing process or incorrect cutting dimensions. Quick fixes often involve inspecting and recalibrating settings, while persistent or more serious issues should prompt consultation with a technician. Understanding these common problems can help operators take proactive measures to maintain machine performance.

Safety features of tablet strip packing machines

Safety is paramount in the operation of tablet strip packing machines. Most machines are equipped with multiple safety mechanisms, including emergency stop switches and safety guards to protect operators from moving parts. These features are essential to ensure a safe working environment, reducing the risk of accidents in high-speed production settings.

Operator safety guidelines should include proper training on machine operation and understanding all safety features. It's also crucial to conduct regular safety checks, inspecting that all safety features are functioning correctly. Maintaining a commitment to safety not only safeguards employees but also contributes to overall operational efficiency.

Industry applications of tablet strip packing machines

Tablet strip packing machines are predominantly used within the pharmaceutical sector for drug packaging, ensuring that products arrive safely to pharmacies and hospitals. Besides pharmaceuticals, they find applications in nutraceuticals and Over-the-Counter (OTC) products, where precise dosing is equally critical.

Their versatility extends to specialized markets, which may utilize organic and herbal tablets, showcasing the flexibility of these machines in accommodating diverse tablet formulations and materials. This adaptability and reliability ensure that tablet strip packing machines remain central to various industries.

Innovations and future trends in tablet strip packing technology

The future of tablet strip packing technology looks promising with continuous advancements in machine design. Recent trends lean towards integrating smart technology that harnesses IoT capabilities, allowing for remote monitoring and adjustments, thus enhancing operational efficiency.

Sustainable packaging solutions are also gaining traction, as manufacturers seek to minimize environmental impact. Innovations may include using biodegradable materials for strips or energy-efficient machinery that consumes less power without compromising output. Trends like these represent a shifting industry paradigm towards more responsible production practices.

Frequently asked questions about tablet strip packing machines

When evaluating tablet strip packing machines, many users wonder how these machines compare to other packaging solutions, such as blister packing machines. While both serve to package tablets, strip packing typically presents a more efficient and cost-effective solution for high-volume operations.

Maintenance requirements are often a concern, as regular upkeep is essential for longevity. Users are advised to establish a maintenance schedule, ensuring components are regularly checked and serviced. Additionally, industry regulations impact packaging choices by mandating compliance with safety and quality standards, which influence the design and materials used.

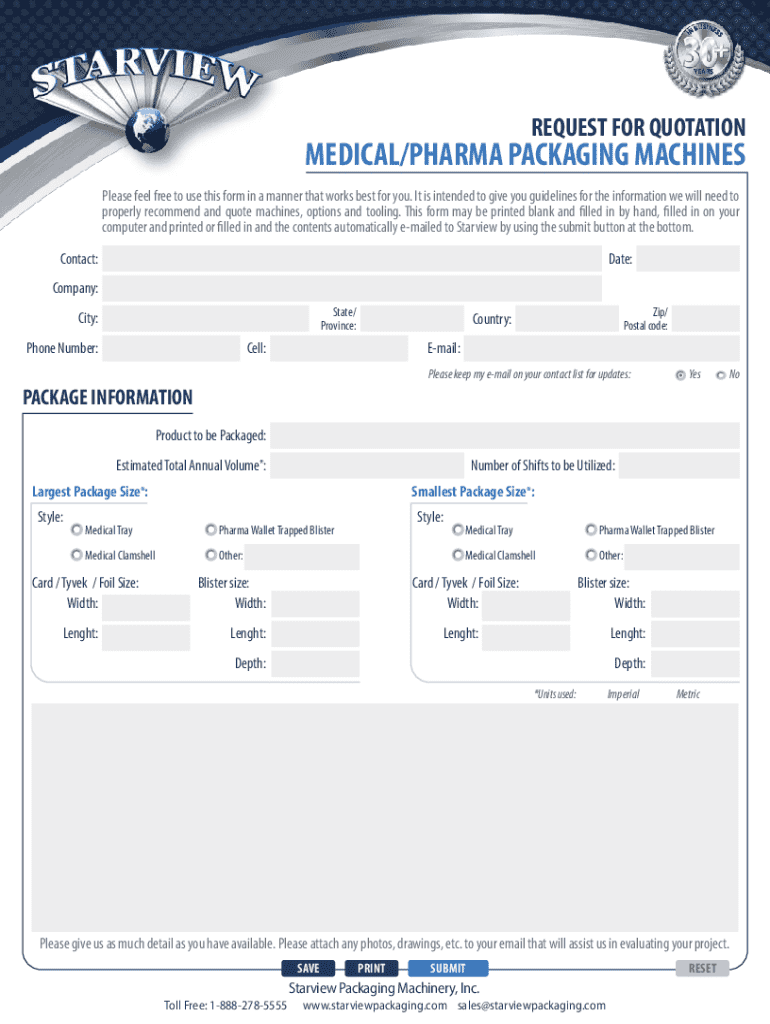

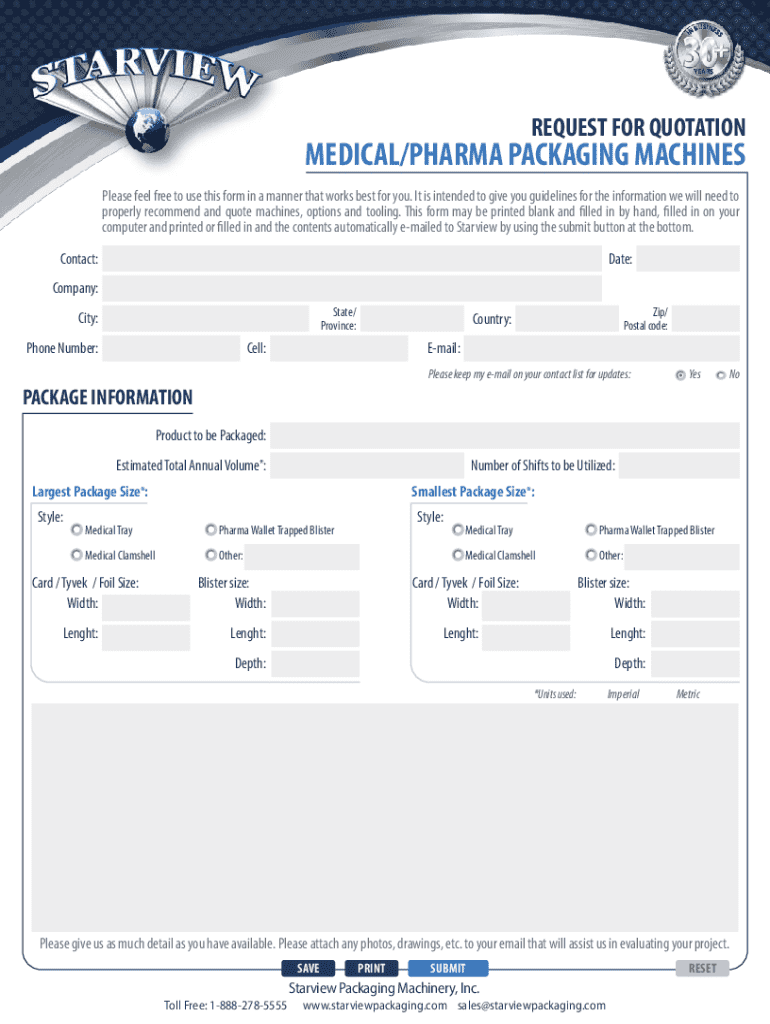

Requesting support and resources from pdfFiller

For those looking to enhance their documentation processes related to tablet strip packing machines, pdfFiller offers a suite of interactive online tools that facilitate easy form management. Users can fill out, edit, sign, and manage the tablet strip packing machine form conveniently from any location with internet access.

Moreover, pdfFiller provides cloud-based document solutions ensuring that all necessary templates are readily accessible. Individuals and teams can efficiently collaborate on documents, updating them in real-time. Should specific queries arise, pdfFiller’s customer support team stands ready to assist with any concerns.

Related products and their specifications

In addition to tablet strip packing machines, various packaging options exist, such as blister packing machines and alternative solutions like bottles and sachets. Blister packing machines, for example, provide another effective method for tablet packaging but differ in terms of presentation and protection offered.

Understanding the specifications of these related products is crucial for manufacturers looking to diversify their packaging lines. Each option presents distinct advantages that should be evaluated based on product requirements, market preferences, and operational capabilities.

Conclusion and next steps for users

Investing in a tablet strip packing machine can drive operational efficiency and improve product handling in pharmaceutical manufacturing. For users looking to enhance their processes, adopting new technologies for efficiency is crucial. Exploring the capabilities of pdfFiller can streamline documentation and approval processes related to tablet strip packing machines, providing further benefits.

Individuals and teams are encouraged to take advantage of the resources available on pdfFiller for further guidance and learning opportunities. As the industry continues to evolve, staying informed about trends and innovations will empower users to make well-informed decisions that support their operational goals.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I complete tablet strip packing machine online?

How do I edit tablet strip packing machine online?

Can I edit tablet strip packing machine on an Android device?

What is tablet strip packing machine?

Who is required to file tablet strip packing machine?

How to fill out tablet strip packing machine?

What is the purpose of tablet strip packing machine?

What information must be reported on tablet strip packing machine?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.