Get the free OPERATIONOF INDUSTRIAL EFFLUENT TREATMENT SYSTEMS

Get, Create, Make and Sign operationof industrial effluent treatment

How to edit operationof industrial effluent treatment online

Uncompromising security for your PDF editing and eSignature needs

How to fill out operationof industrial effluent treatment

How to fill out operationof industrial effluent treatment

Who needs operationof industrial effluent treatment?

Operation of Industrial Effluent Treatment Form

Understanding the importance of industrial effluent treatment

Industrial effluent treatment is a critical process that involves the treatment of wastewater produced by industrial activities. Its primary purpose is to remove or neutralize harmful pollutants before the water is released back into the environment or reused. Proper treatment is essential, as untreated industrial waste can lead to severe environmental damage, including water pollution, which poses risks to aquatic life and can contaminate drinking water sources.

The environmental impact of untreated industrial waste is profound. Pollutants can accumulate in natural water bodies, disrupting ecosystems and harming wildlife. Furthermore, industrial activities are closely monitored by environmental regulatory agencies, enforcing laws that require compliance with strict effluent quality standards. Adhering to these regulations is not just a legal obligation but also reflects a company's commitment to sustainability and corporate social responsibility.

Key components of an industrial effluent treatment system (IETS)

An effective industrial effluent treatment system (IETS) comprises various components, each designed to tackle specific types of pollutants. The treatment process typically involves several stages, including:

Choosing the right treatment method for your needs often depends on the industry type, the characteristics of the effluent, and regulatory requirements. It's crucial to conduct thorough assessments to ensure the selected methods effectively address contaminant removal and comply with environmental standards.

Regulatory guidelines and standards for effluent treatment

Compliance with regulatory guidelines is mandatory for industries involved in waste disposal. Various governing bodies, such as the Environmental Protection Agency (EPA) in the United States or corresponding agencies worldwide, set stringent standards for effluent quality. These regulations ensure that industries minimize their environmental footprint and protect public health.

Key standards for industrial effluent typically involve limits on constituents such as heavy metals, biological oxygen demand (BOD), and chemical oxygen demand (COD). Non-compliance can result in severe penalties, including financial fines, operational shutdowns, or legal actions. Industries must stay informed about regulatory changes and proactively implement necessary modifications to their treatment processes.

Designing your industrial effluent treatment system

Designing an effective IETS requires careful consideration of multiple factors. Each industry has unique needs based on the type of waste produced and existing site-specific conditions. For instance, chemical processing plants may generate different types of pollutants compared to textile manufacturers. Therefore, understanding the characteristics of your effluent is essential.

Local regulations also play a critical role in the design process. Depending on the jurisdiction, various requirements may dictate treatment methodologies or effluent quality limits, impacting the overall design. Common design pitfalls include inadequate capacity planning, failure to incorporate redundancy, and neglecting to factor in future expansions or changes in discharge volume.

Challenges in industrial effluent treatment operations

Industrial effluent treatment operations face numerous challenges, from technological limitations to operational inefficiencies. Some common issues include equipment failures, fluctuating effluent quality, and insufficient trained personnel. As these challenges can compromise compliance and treatment efficacy, it's vital to address them proactively.

Technological solutions, including automation and real-time monitoring systems, have emerged to mitigate many of these challenges. Regular maintenance and monitoring also play a crucial role in ensuring that treatment processes remain effective and reliable. Engaging a skilled workforce trained in modern treatment techniques can further boost operational efficiency.

Data collection and monitoring your effluent treatment process

Monitoring the performance of an IETS is integral to maintaining compliance and ensuring operational efficiency. Best practices for tracking performance metrics include establishing clear Key Performance Indicators (KPIs), such as influent and effluent quality, operational uptime, and treatment costs.

Automation has revolutionized the monitoring landscape by enabling real-time data collection. Digital solutions can streamline effluent management, providing actionable insights that improve decision-making. Utilizing cloud-based platforms, like pdfFiller, allows teams to access and review documents related to effluent treatment operations from any location, facilitating collaboration and enhancing management efficiency.

Case studies: Successful industrial effluent treatment implementations

Examining successful case studies offers valuable insights into effective industrial effluent treatment. For instance, a major textile manufacturer implemented a biological treatment system that significantly reduced the BOD levels of its effluent. This not only enabled compliance with local regulations but also improved the quality of the water discharged into nearby waterways.

Lessons learned from these projects highlight the importance of planning, stakeholder engagement, and adaptability. Effective collaboration between engineering teams, regulatory agencies, and environmental consultants ensures that the implemented systems meet both technical and legal requirements.

Future trends in industrial effluent treatment technology

Innovations are continually shaping the future of industrial effluent treatment technologies. New methods such as advanced oxidation processes, membrane bioreactors, and electrochemical treatment systems are making wastewater treatment more efficient and sustainable. The industry is leaning towards greener technologies that prioritize sustainability, helping companies reduce their carbon footprints.

As future regulatory changes emerge, organizations must be ready to adapt. Keeping abreast of trends such as bioremediation and the circular economy concept can provide strategic advantages, allowing companies to innovate in treatment approaches while maintaining compliance.

Interactive tools for managing your industrial effluent treatment documents

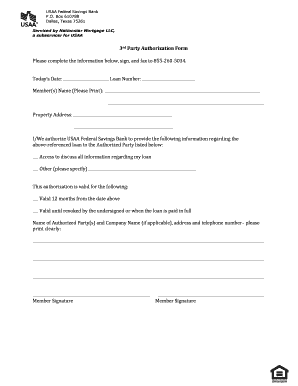

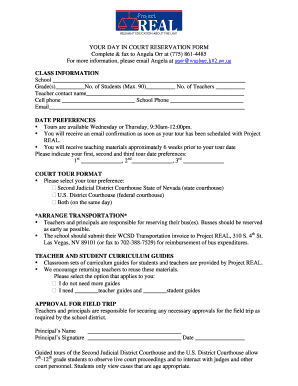

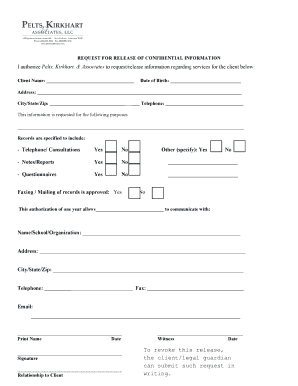

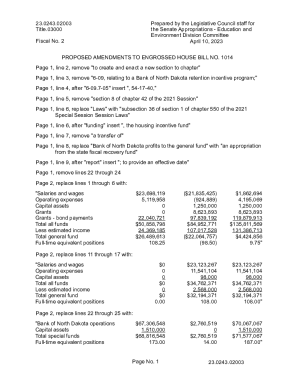

Effective management of documents related to industrial effluent treatment is vital for maintaining compliance and efficient operations. Tools like pdfFiller streamline document creation, allowing users to easily fill out, edit, and eSign necessary forms related to IETS. Its collaborative features facilitate teamwork and enable multiple stakeholders to interact with documents in real-time.

pdfFiller also ensures that you can access and store essential forms securely in a cloud environment, making it easy to retrieve information whenever necessary. This centralized document management approach enhances accountability and minimizes the risk of errors in record-keeping.

Ensuring continuous improvement in your effluent treatment process

To maintain optimal operation of industrial effluent treatment forms, organizations must establish metrics for ongoing evaluation. Regularly assessing performance not only ensures compliance but also identifies opportunities for improvement. Implementing feedback loops strengthens the ability to respond to issues and enhance treatment outcomes.

Engaging employees in continuous learning and development is essential. Training programs and workshops can help staff stay updated about the latest technologies and regulatory changes, fostering an environment of improvement and operational excellence.

Frequently asked questions about industrial effluent treatment

Concerns and misconceptions about industrial effluent treatment are common. Industries often wonder about the preparation required for inspections and the documentation needed for compliance. It is vital to have comprehensive records of treatment processes, effluent quality, and maintenance activities to demonstrate compliance during audits.

Guidance on reporting and documentation can also alleviate concerns about unforeseen compliance issues. By maintaining clear, accurate records and regularly reviewing them, industries can better navigate regulatory requirements and demonstrate their commitment to environmental stewardship.

Contact information and support for industrial effluent treatment solutions

Accessing expert help and consultation can bolster an organization's ability to manage its industrial effluent treatment practices effectively. Many resources are available for ongoing learning, including workshops, webinars, and industry conferences that can enhance knowledge and inspire best practices.

Connecting with professional communities through networks and associations provides valuable opportunities for collaboration and knowledge sharing. These connections can foster innovation and improvement within your operations, ensuring long-term success in effluent management.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Where do I find operationof industrial effluent treatment?

How do I edit operationof industrial effluent treatment online?

How do I edit operationof industrial effluent treatment on an iOS device?

What is operation of industrial effluent treatment?

Who is required to file operation of industrial effluent treatment?

How to fill out operation of industrial effluent treatment?

What is the purpose of operation of industrial effluent treatment?

What information must be reported on operation of industrial effluent treatment?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.