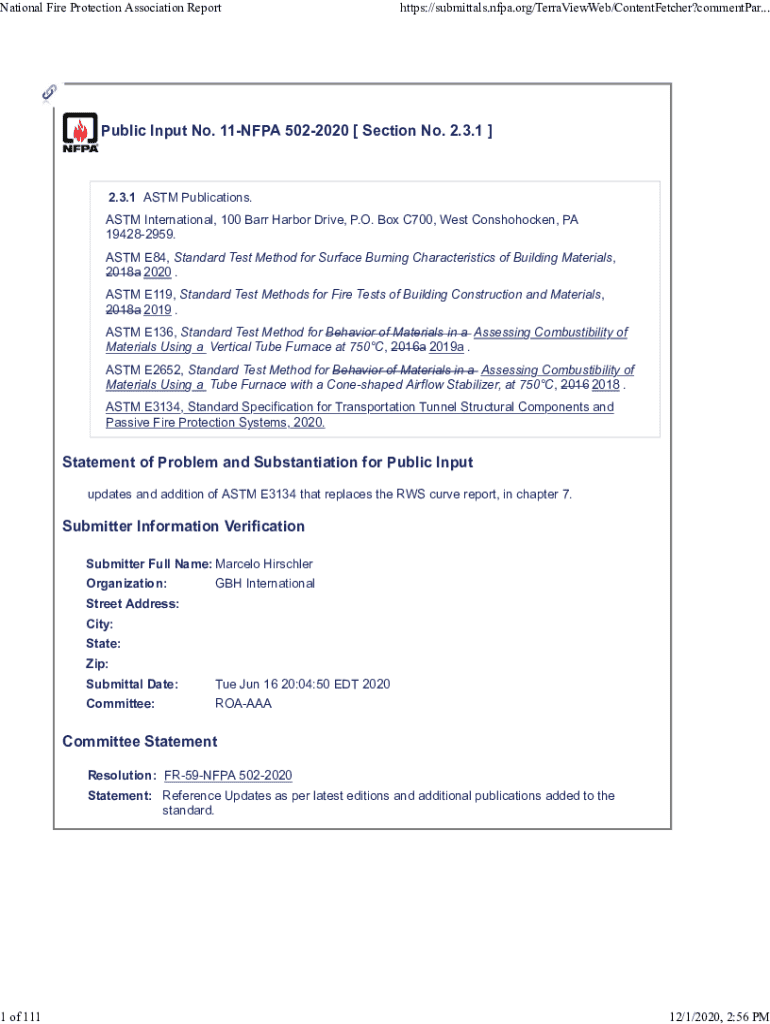

Get the free Materials Using a Vertical Tube Furnace at 750C, 2016a 2019a

Get, Create, Make and Sign materials using a vertical

How to edit materials using a vertical online

Uncompromising security for your PDF editing and eSignature needs

How to fill out materials using a vertical

How to fill out materials using a vertical

Who needs materials using a vertical?

Materials using a vertical form: A comprehensive guide

Understanding vertical form (materials context)

Vertical Form Fill Seal (VFFS) is a packaging technique that involves forming a tube from a flat roll of film, filling it with product, and then sealing it at the same time. This packaging solution is essential in a wide array of industries due to its efficiency and versatility in handling various types of materials.

The importance of VFFS in packaging stems from its ability to streamline operations, reduce waste, and maintain product quality. Unlike traditional packaging methods that can utilize rigid containers, VFFS adapts well to different product types and can minimize the packaging footprint, making it an economical and eco-friendly choice.

Types of materials suitable for vertical form

Different materials can be packaged using vertical forms, each chosen based on specific requirements for product safety, stability, and shelf-life. Understanding these materials is crucial for maximizing the VFFS process.

Flexible packaging materials

Plastic films offer numerous options for VFFS applications, including polypropylene and polyethylene. These materials are lightweight, moisture-resistant, and customizable, making them ideal for a variety of consumables.

Powdered materials

Common powders such as flour and sugar are frequently packaged using VFFS forms. The behavior of powders during filling is critical; they can clump or compact, necessitating precise control over the filling process to ensure accuracy.

Granular materials

Ideal candidates for vertical form packaging include coffee and rice. The flowability of granular materials poses unique challenges, as achieving consistent portioning is vital for product quality.

Liquid materials

VFFS is also compatible with liquid materials, such as sauces and oils. Each liquid requires specific handling techniques to manage flow while ensuring a secure seal.

Key features and benefits of materials used

The choice of materials in VFFS packaging directly impacts the shelf-life and safety of products. Packaging materials must possess strong barrier properties to protect against moisture, oxygen, and light exposure.

Branding opportunities are abundant, and custom printing options can enhance product visibility while providing essential product information. As sustainability becomes a growing concern, the recyclability of packaging materials is increasingly vital for consumer preference.

Choosing the right material for your product

Selecting the ideal material necessitates a keen understanding of your product's unique requirements. For instance, establishing a correlation between product type and material compatibility is crucial to ensuring stability and extending shelf-life.

Considerations must be made for perishable versus non-perishable products, as different materials may offer varied levels of protection. Packaging size and shape also pose factors in material selection, enabling configurations like pouches and bags that maximize storage and display efficiency.

Special features for enhanced protection

Advanced features such as vacuum sealing and gas flushing can dramatically enhance the preservation of products. In addition, moisture barriers and UV protection are essential in preventing degradation.

The process of vertical form fill seal (VFFS)

Understanding the VFFS process provides insight into how materials can lead to efficient packaging. It begins with sourcing raw materials and requires careful preparation to ensure seamless filling. Material characteristics dictate machinery setup, influencing components like filling mechanisms and sealing methods.

Filling techniques vary for different materials. For instance, scales and augers ensure precision for powders and granular materials. The sealing and discharge process is critical, necessitating robust quality assurance measures to mitigate errors during bag discharge.

Innovations in materials for vertical form applications

The landscape of packaging materials is evolving, with exciting innovations enhancing the efficiency and environmental friendliness of vertical forming technology. Emerging trends include compostable films and multi-layered structures with enhanced barrier properties.

Case studies exhibit how companies are adopting sustainable materials, showcasing innovations that align with consumer expectations and regulatory requirements. As the demand for sustainable packaging rises, VFFS will implement practices that advance environmental responsibility.

Considerations when selecting vertical form fill seal systems

Investing in VFFS systems requires evaluating operational speed and output specific to your packaging needs. Compatibility with the selected materials ensures that the equipment enhances rather than impedes the production process.

It is essential to weigh the investment against return on packaging materials, ensuring a balance between cost-effectiveness and quality. Partnering with reliable equipment manufacturers guarantees access to support and ongoing innovations.

Applications across industries

VFFS techniques are extensively utilized across several industries, making the selection of the correct materials crucial for efficacy.

The food and beverage sector relies on VFFS for packaging snack foods, frozen meals, and powdered products, all of which demand specific protective qualities. Similarly, the pharmaceutical industry utilizes VFFS for sterile packaging of medical devices and products, prioritizing safety and compliance.

Best practices for material management in VFFS

Regular maintenance of packaging materials ensures that they remain effective in protecting products. Proper storage conditions are essential to prevent degradation from factors such as humidity and temperature variations.

Training staff on the handling of various materials used in VFFS promotes better quality control and reduces operational errors, ultimately enhancing production efficiency.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I manage my materials using a vertical directly from Gmail?

How can I get materials using a vertical?

How do I edit materials using a vertical on an Android device?

What is materials using a vertical?

Who is required to file materials using a vertical?

How to fill out materials using a vertical?

What is the purpose of materials using a vertical?

What information must be reported on materials using a vertical?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.