Get the free Badger-Meter-M2000-Electromagnetic-Flow-Meter-Manual ...

Get, Create, Make and Sign badger-meter-m2000-electromagnetic-flow-meter-manual

How to edit badger-meter-m2000-electromagnetic-flow-meter-manual online

Uncompromising security for your PDF editing and eSignature needs

How to fill out badger-meter-m2000-electromagnetic-flow-meter-manual

How to fill out badger-meter-m2000-electromagnetic-flow-meter-manual

Who needs badger-meter-m2000-electromagnetic-flow-meter-manual?

Comprehensive Guide to the Badger Meter M2000 Electromagnetic Flow Meter Manual

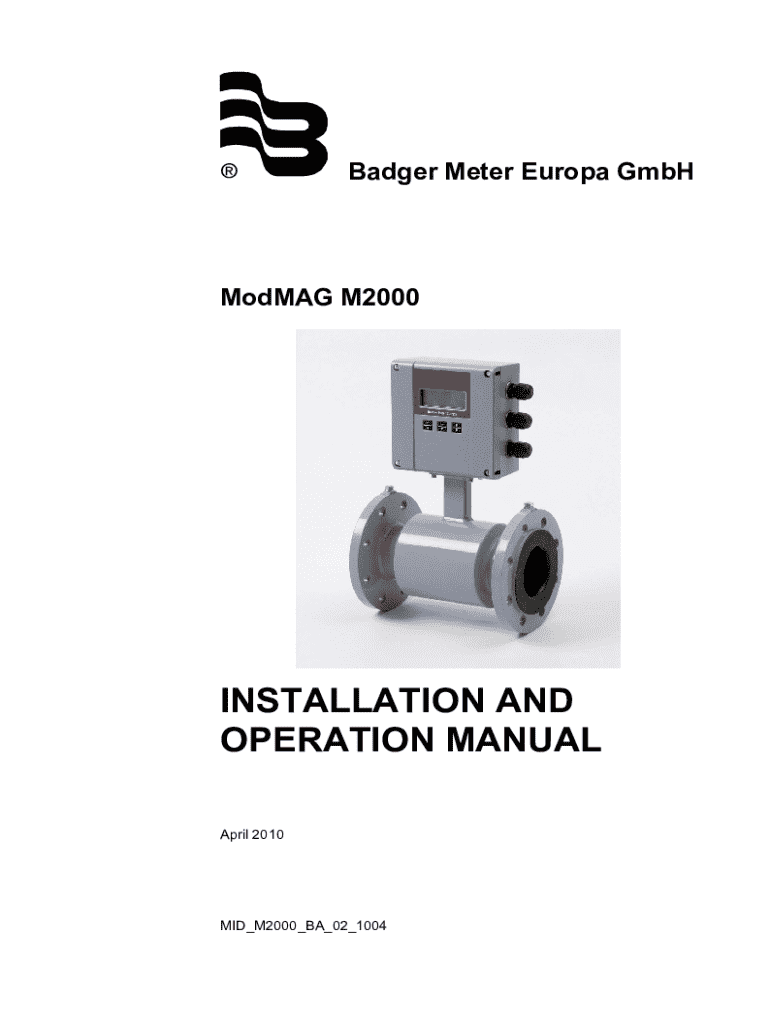

Overview of Badger Meter M2000

The Badger Meter M2000 electromagnetic flow meter is a cutting-edge instrument designed for accurate fluid measurement in a variety of applications. This device utilizes electromagnetic principles to measure flow rates in a non-intrusive manner, offering unparalleled accuracy for both conductive and non-conductive liquids. The M2000 is particularly well-suited for industrial sectors including water treatment, chemical processing, and food and beverage industries.

Key features include a robust construction, a wide measurement range, and compatibility with various piping configurations. The M2000 supports both Bluetooth and wired connections for data transmission, making it an ideal choice for those who require real-time monitoring and data logging. Its user-friendly interface further enhances its practicality, allowing operators to easily configure settings and access data.

Importance of electromagnetic flow measurement

Electromagnetic flow measurement technology is crucial in industries that require precise fluid flow monitoring. This method provides a wide range of applications, including water management, wastewater treatment, and the chemical industry. With its ability to measure fluids with varying viscosities and densities, electromagnetic flow meters offer a level of versatility that traditional flow measurement technologies often lack.

The primary benefit lies in the non-contact measurement abilities, which prevent any obstruction or contamination of fluid paths. Additionally, these meters are less prone to wear since there are no moving parts required, leading to lower maintenance costs over time.

Getting started with Badger Meter M2000

Initiating your journey with the Badger Meter M2000 begins with unboxing and setting up the device. Carefully check the package for completeness, which typically includes the flow meter, power supply, mounting hardware, installation manual, and calibration certificate. Ensure that you familiarize yourself with all included components before proceeding to assembly.

Visual aids in the installation manual will guide you through the assembly process. Make sure to follow the instructions precisely to avoid any connectivity issues. It's important to choose an appropriate location for installation that minimizes the risk of vibrations and obstructions, which can affect performance.

Key specifications

The Badger Meter M2000 is designed to perform optimally in various conditions. It is compatible with a wide range of applications, operating effectively in sizes from 0.5 inches to 24 inches in diameter. The measurement range is typically between 0.1 to 30 meters per second, depending on the fluid viscosity and configuration.

Accuracy is a hallmark of the M2000, with a standard deviation within ±0.5%, making it an industry leader in precision. It's also available in various material selections such as stainless steel and PVC, catering to the needs of specific applications and environmental conditions.

Detailed instructions for operation

To begin operating the Badger Meter M2000, first ensure that your flow meter is properly installed and connected to an appropriate power supply. A checklist should include verifying that adapters and electrical connections meet the specifications outlined in the manual, protecting against voltage surges and ensuring robust grounding. After confirming all connections, you can power the flow meter on.

Upon powering on, the device will undergo a series of self-checks. Follow the step-by-step guide in the manual for turning the power on, which generally involves pressing the designated power button until the display activates. If an error occurs during this process, refer to the troubleshooting section of the manual for specific instructions.

Interface walkthrough

The Badger Meter M2000 features an intuitive interface that provides operators with easy access to all necessary functions. Key buttons include the 'Menu', 'Select', and 'Back' buttons. Navigating through the settings menu allows users to adjust flow parameters, set alarms, and examine historical data logs.

The digital display will show real-time flow readings as well as alerts for any operational issues. Familiarizing yourself with these display features will enable you to optimize the settings effectively and ensure consistent performance.

Configuration and calibration

Setting up measurement parameters on the Badger Meter M2000 is crucial for obtaining accurate flow readings. Start by accessing the measurement units option in the settings. You can select various units such as Gallons Per Minute (GPM) or Liters Per Minute (LPM) suited to your preferences and operational needs.

Next, input pipe dimensions and fluid characteristics, including density and viscosity if available. Calibrating the meter is a vital process that should not be overlooked. Calibration ensures that the readings are accurate based on the specific characteristics of the fluids being measured. A detailed calibration guide is provided in the user manual, typically involving a series of controlled flow tests.

Calibrating for accurate measurements

Calibration is best performed under steady conditions for the most reliable outcomes. Follow these steps: adjust the flow settings according to the fluid type, run the fluid through the meter at controlled rates, and verify against a known standard. Regular calibration is important; it is advised to calibrate the flow meter to match new or altered operating conditions, ideally every 6-12 months.

Maintenance tips for optimal performance

Routine maintenance of the Badger Meter M2000 is essential for ensuring long-term reliability and accuracy. Daily checks should include inspecting the flow meter for any visible damage or misalignment. Weekly, it’s beneficial to look for any abnormal fluctuations in flow readings, which could signal potential issues.

Monthly maintenance tasks might involve cleaning any sensors and checking electrical connections to ensure all components are secure and functioning. A visual inspection checklist included in the manual can guide users through these routines effectively.

Troubleshooting common issues

Identifying and resolving common operational problems can save time and money. Some frequent issues include incorrect flow readings, which might stem from improper calibration or blockages in the flow path. Always refer back to the manual for troubleshooting guidance; it provides solutions for the top ten frequently encountered issues.

FAQs are also compiled to address general inquiries regarding installation, such as wiring concerns and initial setup. For more complicated issues, accessing technical support as listed in the warranty information could be crucial.

Integration with other systems

Connecting your Badger Meter M2000 to data monitoring systems enhances its functionality significantly. This integration allows for remote tracking of fluid metrics and efficient data collection for thorough analysis. The flow meter supports various data transmission protocols, making it adaptable to many established data logging frameworks.

Most commonly, it integrates with SCADA (Supervisory Control and Data Acquisition) systems, ensuring real-time data is available for operational oversight. Understanding the software compatibility and integration options is necessary for users aiming to maximize functionality.

Network configuration options

Setting up remote monitoring involves configuring the network settings within the device. Utilize the manual to guide through the process of enabling Bluetooth or wired network options. Implementing essential security measures for data transmission, like encryption methods, is critical to protect sensitive information.

Ensuring that all network configurations adhere to your organization’s IT policies can prevent data breaches and improve the reliability of the system.

User experiences and testimonials

Feedback from users across various industries illustrates the M2000’s versatility and efficiency. In one case study, a chemical processing plant reported significant improvements in measurement accuracy, allowing for better inventory management and reduced waste. Similarly, a water treatment facility noted that the M2000 provided real-time data critical for regulatory compliance.

Quantifiable benefits reported include enhanced operational efficiencies by up to 30% and a substantial reduction in maintenance costs compared to other flow measurement methods. The positive sentiment surrounding the Badger Meter M2000 showcases its impact on productivity and bottom-line results.

Frequently asked questions

General inquiries about the installation process often arise among new users. Users frequently ask about electrical connections, available power supply voltages, and the best practices for installation. It's recommended to refer to the installation manual for detailed steps on each aspect, or consult technical support for specialized assistance.

As for technical support and warranty information, users can rely on a well-documented support resource available on the manufacturer’s website. Warranty coverage typically includes parts and support for a specified period post-purchase, ensuring that you have ample time to resolve any issues that may arise.

Related products and accessories

To complement your Badger Meter M2000, consider recommended accessories such as compatible installation kits, signal conditioners, and calibration devices. Utilizing the right accessories can optimize performance, as well as provide seamless integration into existing systems.

Additionally, exploring alternative models within the Badger Meter range allows users to find a suitable fit for different needs, whether it’s for higher capacities or specific industry applications. Each model boasts unique features tailored to meet diverse operational requirements.

Conclusion: maximizing your Badger Meter experience

The Badger Meter M2000 stands out due to its accuracy, durability, and ease of use, making it a trustworthy companion in fluid management. Recapping its advantages, users benefit from non-intrusive measurement, versatile applications, and robust integration capabilities that can significantly elevate operational efficiency.

To enhance document management pertaining to the Badger Meter M2000, leveraging pdfFiller streamlines the process for users. With pdfFiller, you can easily fill out forms, edit documents, and acquire eSignatures efficiently, making documentation associated with the flow meter management a breeze.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I manage my badger-meter-m2000-electromagnetic-flow-meter-manual directly from Gmail?

How do I fill out badger-meter-m2000-electromagnetic-flow-meter-manual using my mobile device?

How do I edit badger-meter-m2000-electromagnetic-flow-meter-manual on an Android device?

What is badger-meter-m2000-electromagnetic-flow-meter-manual?

Who is required to file badger-meter-m2000-electromagnetic-flow-meter-manual?

How to fill out badger-meter-m2000-electromagnetic-flow-meter-manual?

What is the purpose of badger-meter-m2000-electromagnetic-flow-meter-manual?

What information must be reported on badger-meter-m2000-electromagnetic-flow-meter-manual?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.