Get the free Bending the Curve (Part IV) - Consumption, Status, and ...

Get, Create, Make and Sign bending form curve part

How to edit bending form curve part online

Uncompromising security for your PDF editing and eSignature needs

How to fill out bending form curve part

How to fill out bending form curve part

Who needs bending form curve part?

Bending form curve part form: A Comprehensive Guide

Understanding bending forms

Bending forms are essential in various industrial processes, particularly in the fabrication of metal components. The primary purpose of bending forms is to enable the creation of parts with specific geometries through the application of force, resulting in advantageous properties in their final applications. Bending forms are critical not only for functionality but also for aesthetic purposes in product design.

The significance of bending forms extends beyond simple shaping; they play a vital role in the assembly and performance of products. Understanding the underlying mechanics of bending can significantly impact the efficiency and quality of production processes, making the study of bending forms indispensable in fields like automotive, aerospace, and product design.

Types of bending curves

Bending curves can be categorized into three primary types: linear bends, compound bends, and complex curves. Each type presents unique characteristics and is suitable for different applications, demanding distinct techniques and considerations.

Linear bends

Linear bends involve a simple, consistent curve along a single axis. This type of bend is commonly found in applications such as metal brackets and structural components, where uniform strength and stability are required. Linear bends can typically be achieved quickly and with minimal tooling adjustments, making them an efficient choice for many manufacturers.

Compound bends

In contrast, compound bends involve multiple bending axes, allowing for more complex shapes. These bends are frequently used in products like automotive frames and pipe fitting, where spatial constraints demand intricate designs. The process of creating compound bends is more challenging, often requiring specialized equipment and a keen understanding of the material behavior during bending.

Complex curves

Complex curves are the most intricate bending forms, encompassing freeform shapes and varying radii. This type of bending is typically employed in artistic and architectural applications, where aesthetic appearance and fluid lines are crucial. Techniques such as incremental bending or the use of CNC bending machines are often utilized to achieve the precision required for complex curves.

Selecting the right bending method

Choosing the correct bending method is crucial for the success of bending form applications. Several factors must be taken into account to ensure optimum results.

When comparing common methods, air bending stands out for its versatility, allowing for more significant angle variations, while bottom bending is preferred for producing precise angle outcomes. Similarly, using a press brake offers excellent control over the bending process, making it ideal for both linear and compound bends.

Interactive tools for bending calculations

Embracing technology in the design and fabrication processes, interactive tools for bending calculations streamline the workflow by providing precise data essential for successful bending operations. These tools come equipped with user-friendly interfaces that simplify the complex calculations needed for bending forms.

To utilize these tools effectively, follow this step-by-step guide:

Detailed instructions for creating bending form curves

Creating bending form curves involves several critical steps, each important to ensure the final product meets quality standards.

Step 1: Gather necessary tools and materials

Start with gathering the right tools, such as a bending brake, measuring instruments, and clamps. Proper material selection is equally vital; opt for the material that suits both the design and the functional requirements. It’s important to factor in the material’s bendability and tensile strength.

Step 2: Measure and mark the material

Accurate measurements are essential. Utilize quality measuring devices and double-check measurements against your design specifications to avoid costly errors. Common pitfalls to avoid include misreading measurements and overlooking the necessary allowances for bends.

Step 3: Set up the bending equipment

Proper setup of your bending equipment is crucial for ensuring safety and quality output. Secure the material and adjust all necessary settings according to the specifications defined during the design phase.

Step 4: Execute the bending process

When executing the bends, consistently monitor the process, making adjustments as needed. Aim to maintain uniformity across all bends for enhanced product quality.

Step 5: Inspect and adjust the finished part

Thoroughly inspect each finished part for any defects such as incorrect angles or material inconsistencies. Implement quality control measures and make final adjustments to ensure precision before concluding the production process.

Common challenges in bending form curves

Despite advancements in bending techniques, challenges remain prevalent in the process of creating bending form curves. Identifying these challenges is the first step toward effective troubleshooting.

Troubleshooting techniques can help alleviate these challenges. For example, ensuring adequate edge preparation can minimize cracking, while fine-tuning equipment settings can assist in achieving more precise angles.

Best practices for bending form curves

Developing best practices for bending form curves is essential for maturing your fabrication processes and improving product quality.

Material preparation

Proper material preparation techniques can enhance bend quality significantly. Techniques such as heating specific metals can increase their ductility, making them less prone to cracking during the bending process.

Bending techniques to enhance accuracy

Incorporate suggestions from industry experts by carefully selecting your bending equipment, employing automated machines, and consistently maintaining them to uphold performance standards. Continuous training on bending techniques can also empower your workforce to achieve precise and consistent outcomes.

Post-bend finishing techniques

Post-bend finishing treatments such as deburring and surface treatment are crucial for ensuring both quality and longevity in a part's lifecycle. These techniques not only enhance the part's appearance but also provide protection against corrosion and wear.

Case studies: Successful bending form applications

Real-world applications of bending forms can provide valuable insights into effective techniques. For instance, the automotive industry often showcases advanced bending methods to reinforce precision while maintaining weight efficiency in their framing systems. By analyzing these case studies, manufacturers can glean lessons about material choices, tooling selection, and innovative processes.

Such case studies highlight best practices derived from industry leaders, offering a roadmap for smaller businesses to adopt these practices and continuously improve their capabilities.

Community insights and resource sharing

Engagement within the bending and fabrication community can be incredibly beneficial. Forums and platforms allow individuals and teams to share experiences, seek advice, and discuss challenges related to bending form curve part forms.

Feedback from peers not only enhances individual knowledge but helps create a collective wisdom that can drive industry standards. Participation in discussions around experiences and challenges can lead to shared solutions and broaden your understanding of the diverse applications of bending forms.

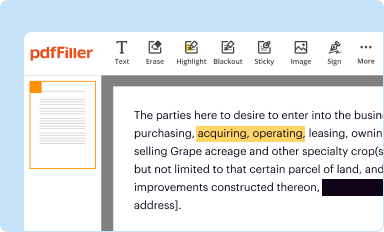

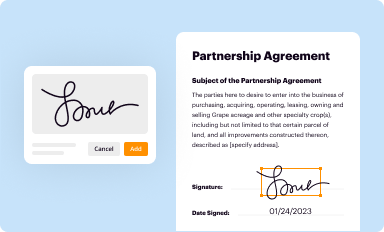

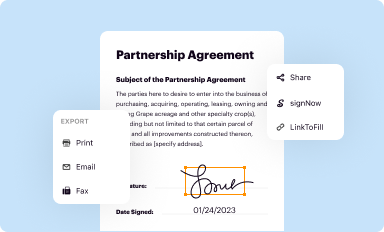

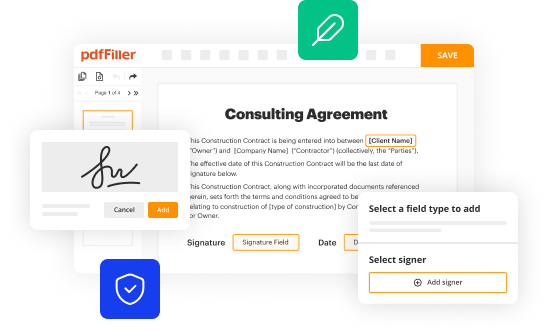

Navigating pdfFiller for document management

pdfFiller stands out as a comprehensive solution for managing bending forms and associated documentation. Whether creating new bending forms or editing existing documents, pdfFiller allows users to streamline the process effortlessly.

The platform facilitates seamless integration with bending plans and enables eSigning for swift approval processes, heightening productivity and efficiency in document management.

Additional tools and templates on pdfFiller

Exploring the available templates related to bending forms on pdfFiller can significantly enhance your productivity. The customizable templates allow users to tailor documents to fit specific needs, ensuring clarity and ease of use.

By utilizing these resources effectively, teams can enhance collaboration, minimize errors, and optimize workflow across fabrication and design processes.

Stay updated with industry trends

Keeping abreast of evolving bending techniques and industry innovations is crucial for maintaining a competitive edge. The advent of new technologies in bending, such as automated controls and advanced materials, is reshaping traditional practices and introducing efficiencies previously unattainable.

Engage with ongoing learning opportunities and educational resources to remain informed about the latest developments in bending technologies, ensuring that your practices align with contemporary industry standards.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I manage my bending form curve part directly from Gmail?

How can I edit bending form curve part from Google Drive?

How do I fill out bending form curve part on an Android device?

What is bending form curve part?

Who is required to file bending form curve part?

How to fill out bending form curve part?

What is the purpose of bending form curve part?

What information must be reported on bending form curve part?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.