Get the free Adaptive Fabrication of Electrochemical Chips with a Paste ... - hardy-plant org

Get, Create, Make and Sign adaptive fabrication of electrochemical

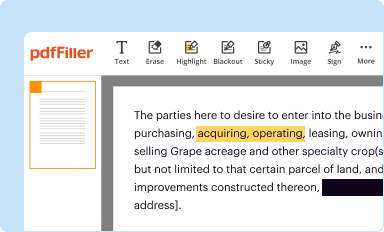

Editing adaptive fabrication of electrochemical online

Uncompromising security for your PDF editing and eSignature needs

How to fill out adaptive fabrication of electrochemical

How to fill out adaptive fabrication of electrochemical

Who needs adaptive fabrication of electrochemical?

Adaptive fabrication of electrochemical form

Overview of adaptive fabrication

Adaptive fabrication refers to the dynamic and flexible production techniques tailored for creating electrochemical forms. In the electrochemical realm, this involves the real-time modification of manufacturing processes to optimize the properties and functionalities of electrochemical devices. This technology is crucial in modern manufacturing and research, enabling the development of customized sensors, batteries, and energy storage solutions that meet specific operational demands.

The importance of adaptive fabrication lies not only in its ability to create complex geometries with high precision but also in its potential to reduce waste and enhance material efficiency. Key applications include the production of advanced batteries, fuel cells, and electrochemical sensors, which are fundamental in sectors like renewable energy, environmental monitoring, and medical diagnostics.

Key concepts in electrochemical fabrication

Understanding electrode materials is foundational in electrochemical fabrication. Electrode materials play a critical role in defining the efficiency and performance of electrochemical devices. Common materials include metals such as gold and platinum, carbon-based materials, and various metal oxides. The selection criteria encompass conductivity, stability, electrochemical activity, and compatibility with the intended application.

Additionally, seeking to understand electrochemical mechanisms is essential. Basic principles of electrochemistry involve redox reactions, where oxidation and reduction occur, transferring electrons between species. The effectiveness of electrochemical reactions directly impacts device performance, highlighting the significance of designing electrodes tailored for specific reactions.

Adaptive fabrication technologies

Various 3D printing techniques have emerged as effective methods for producing electrochemical forms. Notable types include Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS). Each method has distinct advantages; for example, FDM is known for its accessibility and ease of use, while SLA provides higher resolution and material versatility.

Moreover, paste dispensing technology has become an innovative approach in the fabrication of electrochemical devices. This involves delivering conductive pastes to create intricate electrode designs. The benefits of using paste include reduced material waste, flexibility in design, and the possibility of integrating multiple materials, enhancing device functionality.

The adaptive fabrication process

The adaptive fabrication process includes several crucial steps, starting with material preparation. Preparation involves selecting appropriate materials, based on functional requirements, and ensuring that all components meet quality control benchmarks.

Next, designing electrochemical chips entails leveraging computer-aided design (CAD) tools that allow for intricate and efficient designs. Such designs must consider factors like material compatibility, mechanical strength, and electrochemical performance optimization.

The actual 3D printing execution requires precise setup, including parameters such as temperature management, printing speed, and layer thickness, which can dramatically affect final outcomes.

Finally, post-processing is vital. Techniques include curing to enhance the material properties and finishing steps that ensure smooth surfaces and proper material bonding. Integrating multiple materials during fabrication may also require specialized processing to achieve desirable interactions between layers.

Performance evaluation of fabricated electrochemical forms

Performance evaluation is a critical aspect of validating the efficacy of fabricated electrochemical forms. Testing procedures typically involve methods like Cyclic Voltammetry, which assesses the electrochemical activity of the electrodes. These tests provide insights into important metrics such as current response, stability, and the overall electrochemical behavior of the device.

Interpreting results from these tests enables engineers to make informed decisions on design and material adjustments, leading to the continuous improvement of chip performance. Strategies here include optimizing electrode surface areas and modifying compositions based on initial testing results.

Innovations in adaptive fabrication

Recent advances in material science are significantly enhancing performance in electrochemical fabrication. Novel materials, including advanced polymers and nanostructured electrodes, are being developed to improve efficiency and reduce degradation over time.

Looking to the future, trends indicate a growing influence of digitalization and automation in electrochemical device manufacturing. As tools become more integrated with data analytics and machine learning, the precision, speed, and customization of electrochemical forms will likely see rapid advancements, making adaptive fabrication increasingly valuable.

Interactive tools for adaptive fabrication

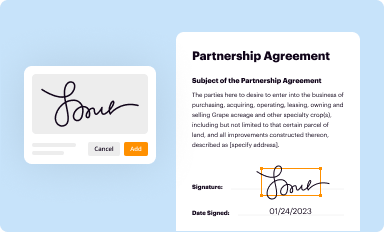

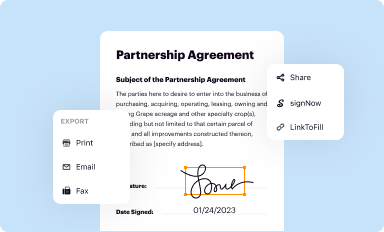

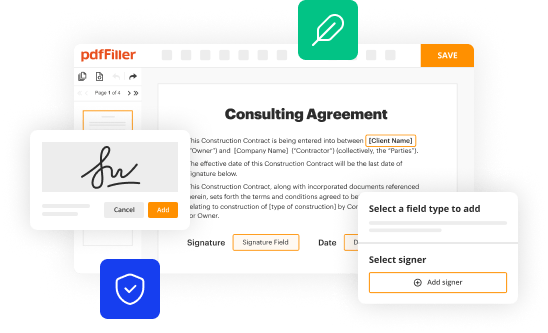

In the context of documenting the fabrication process, pdfFiller provides effective document management solutions. Users can easily create, edit, and share project documentation, ensuring that all team members are aligned throughout the adaptive fabrication lifecycle.

Interactive templates available on pdfFiller facilitate collaboration, making it easier to draft electrochemical project reports. The platform's comprehensive features for document sharing, signing, and management empower seamless collaboration, boosting productivity and ensuring that key information is readily accessible.

Practical guidelines for documenting the fabrication process

Documenting the fabrication process starts with best practices that structure reports effectively. Essential elements to include are detailed material specifications, procedural steps, and performance metrics. This documentation becomes a valuable resource for future improvements and regulatory compliance.

Utilizing pdfFiller for documentation management allows for easy creation and editing of manufacturing documents. Users can take advantage of cloud-based solutions to ensure that all project members have access to the latest information. By following a step-by-step guide to document management, teams can keep their workflow organized, communicate effectively, and maintain a comprehensive trail of the fabrication processes.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Can I create an electronic signature for signing my adaptive fabrication of electrochemical in Gmail?

How do I fill out the adaptive fabrication of electrochemical form on my smartphone?

How do I complete adaptive fabrication of electrochemical on an iOS device?

What is adaptive fabrication of electrochemical?

Who is required to file adaptive fabrication of electrochemical?

How to fill out adaptive fabrication of electrochemical?

What is the purpose of adaptive fabrication of electrochemical?

What information must be reported on adaptive fabrication of electrochemical?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.