Get the free Non-Woven Surface Conditioning

Get, Create, Make and Sign non-woven surface conditioning

Editing non-woven surface conditioning online

Uncompromising security for your PDF editing and eSignature needs

How to fill out non-woven surface conditioning

How to fill out non-woven surface conditioning

Who needs non-woven surface conditioning?

The Essential Guide to Non-Woven Surface Conditioning Form

Understanding non-woven surface conditioning forms

Non-woven surface conditioning forms are essential tools utilized in numerous industries for effective surface preparation and finishing. These forms consist of materials made from non-woven fibers, providing a uniform surface for applying coatings, polishing surfaces, and cleaning residues from various substrates.

The importance of non-woven surface conditioning forms can be seen across several sectors, including manufacturing, automotive, and metalworking. For example, in manufacturing lines, they help ensure that prepared surfaces achieve optimal bonding for adhesives or coatings. In the automotive industry, these forms are indispensable for achieving high-quality finishes on vehicles, while in metalworking, they assist in preparing metal surfaces for welding and painting.

Key features that highlight their benefits include durability, allowing them to withstand rough surfaces without disintegrating; versatility, enabling use on various materials and applications; and efficiency, streamlining the surface preparation process to reduce time and improve results.

Exploring the structure of non-woven surface conditioning forms

Understanding the structure of non-woven surface conditioning forms is crucial for enhancing your workflow. Typically, these forms include a user information section, product specifications, and application guidelines. This helps ensure all necessary data is captured effectively, providing clarity during the surface conditioning process.

Common terminologies that may be encountered include 'abrasive,' 'grit size,' and 'ventilated sheets.' Each term reflects specific features or guidelines associated with these forms. Additionally, optional add-ons such as detailed specification fields or customizations based on project requirements can improve usability.

Step-by-step guide to completing your non-woven surface conditioning form

To complete your non-woven surface conditioning form efficiently, begin by preparing to gather the required information. This includes understanding the materials you’ll be using and ensuring you have accurate measurements for every parameter specified in the form.

When filling out the form itself, each section is critical:

Common mistakes to avoid include omitting critical measurements and failing to verify the compatibility of selected materials.

Tips for editing and managing your non-woven surface conditioning form

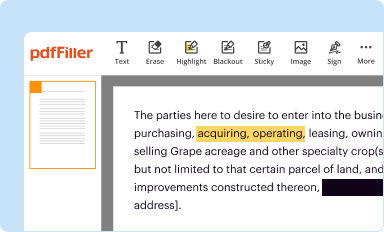

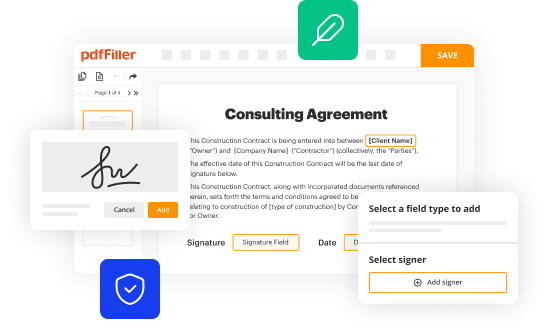

Editing and managing your non-woven surface conditioning form can be made easier with tools like pdfFiller. Utilizing its features allows for streamlined adjustments to your documents. The text editing features are robust, enabling you to make changes effortlessly.

Additionally, inserting images and illustrations can clarify points and instructions. Should you need to collaborate with team members, pdfFiller’s sharing features simplify the process of collecting feedback, ensuring everyone is on the same page.

Maintaining version control is paramount. By tracking changes, you can refer back to previous iterations of the form, ensuring that no details are lost.

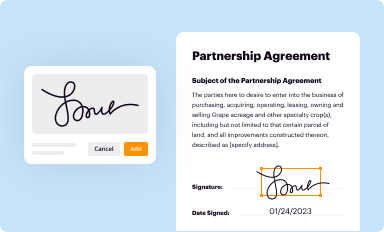

Signing and finalizing your non-woven surface conditioning form

Finalizing your non-woven surface conditioning form is crucial to its efficacy. With pdfFiller, eSigning becomes seamless, allowing you to add signature fields directly where required. You can also utilize signature pads or employ digital signatures to make the process even more user-friendly.

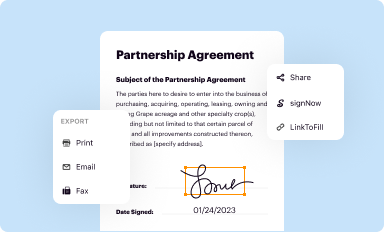

Best practices for secure document management include implementing data encryption techniques and adjusting access control settings. This ensures that sensitive information remains protected while being accessible to authorized personnel.

Frequently asked questions (FAQs)

To further assist users, we’ve compiled a list of frequently asked questions regarding non-woven surface conditioning forms. These address commonly encountered queries:

Case studies: Successful use of non-woven surface conditioning forms

Examining real-life applications of non-woven surface conditioning forms offers insights into their effectiveness. In the manufacturing industry, for instance, companies have reported increased efficiency in surface preparation by 30% after implementing these forms.

Similarly, automotive applications highlight how a major vehicle manufacturer leveraged non-woven conditioning forms, resulting in superior paint adhesion and reduced rework times. Testimonials from industry professionals reinforce these benefits, attesting to the reliability and performance improvements these forms provide.

Staying compliant with data protection and workflow regulations

As with any document management process, maintaining compliance with data protection laws is vital. Organizations must understand the importance of safeguarding sensitive information, particularly when completing non-woven surface conditioning forms.

Key regulatory considerations include ensuring user consent for data collection and maintaining records in a secure manner.pdfFiller’s commitment to compliance and security aids users in navigating these regulatory landscapes with ease.

Innovations in non-woven surface conditioning technologies

The future of non-woven surface conditioning forms looks promising, with ongoing innovations shaping the landscape. New materials, such as advanced synthetic fibers, offer enhanced durability and flexibility, making them suitable for a wider range of applications.

Additionally, trends point toward more sustainable practices, including the use of recycled materials in production. These innovations not only improve efficacy but also align with contemporary environmental considerations, driving towards a greener future in surface conditioning.

Explore additional features of pdfFiller

Beyond its robust functionalities for managing non-woven surface conditioning forms, pdfFiller offers other relevant form templates to suit various needs. With integrations available for other tools and software, it enhances users’ workflows, making document management effortlessly efficient.

Additionally, the resource center provides ongoing learning opportunities, ensuring you stay updated on best practices and emerging trends in document management.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I edit non-woven surface conditioning online?

How do I make edits in non-woven surface conditioning without leaving Chrome?

How can I edit non-woven surface conditioning on a smartphone?

What is non-woven surface conditioning?

Who is required to file non-woven surface conditioning?

How to fill out non-woven surface conditioning?

What is the purpose of non-woven surface conditioning?

What information must be reported on non-woven surface conditioning?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.