Get the free 5 Tray Blast Chiller/Shock Freezer, Reach-In

Get, Create, Make and Sign 5 tray blast chillershock

Editing 5 tray blast chillershock online

Uncompromising security for your PDF editing and eSignature needs

How to fill out 5 tray blast chillershock

How to fill out 5 tray blast chillershock

Who needs 5 tray blast chillershock?

Comprehensive Guide to 5 Tray Blast Chillers and Their Shock Form

Understanding 5 tray blast chillers

Blast chilling is a rapid cooling process utilized predominantly in commercial kitchens. This method involves lowering the temperature of food quickly to below 60°F to halt bacterial growth, thus maintaining food safety and quality. The significance of blast chilling in culinary settings cannot be overstated, as it is essential for preserving ingredients in their peak form, enhancing the overall culinary experience.

A 5 tray blast chiller is designed to carry out this process efficiently, accommodating multiple trays of food at once while ensuring uniform cooling. This capacity makes it an excellent choice for restaurants, bakeries, and catering services where large quantities of food need to be processed simultaneously.

Key features of 5 tray blast chillers

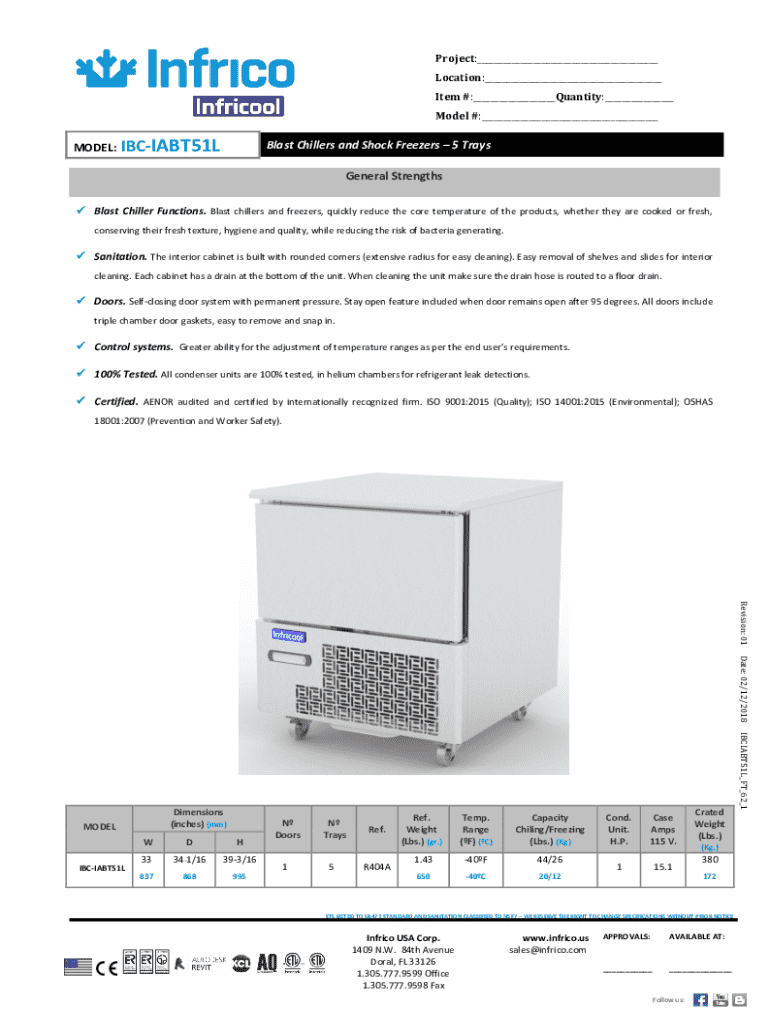

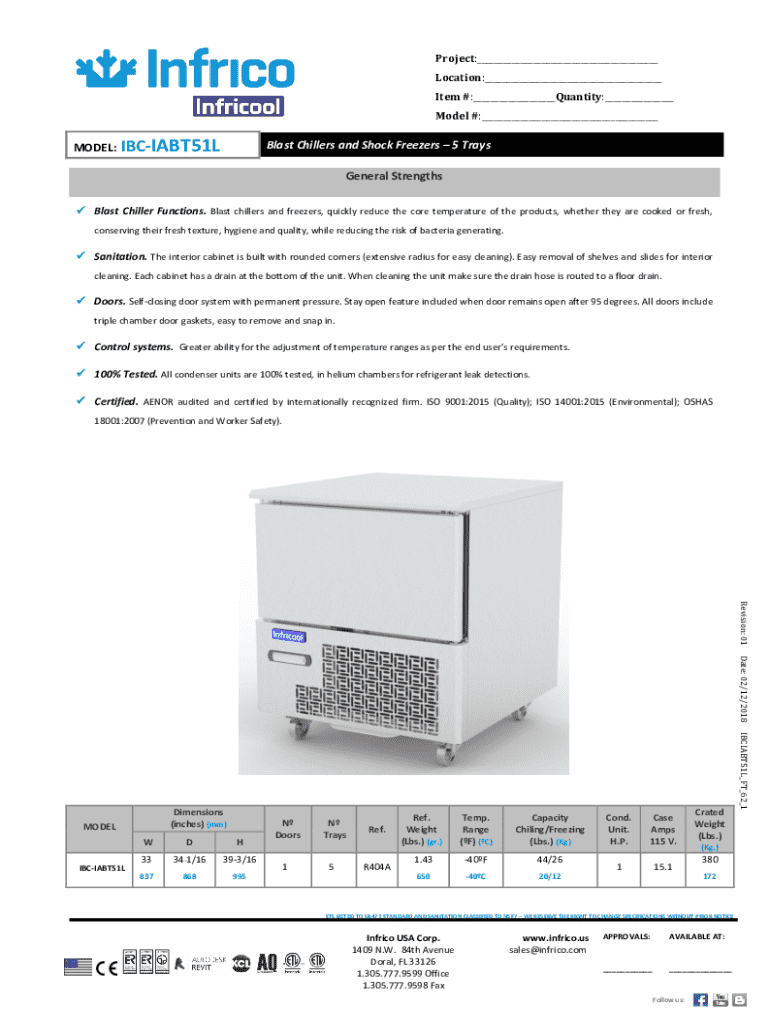

5 tray blast chillers are engineered with a range of technical specifications aimed at optimizing food safety and preservation. They typically operate within a temperature range of +90° to -18°, making them suitable for a diverse array of food types, from meats to pastries. Constructed with durable stainless steel, these chillers not only withstand the rigors of a busy kitchen but also maintain the hygiene standards required in food service.

Size and weight are also critical considerations; a standard 5 tray blast chiller typically measures around 27.5 inches in width, 32 inches in depth, and stands about 60 inches high, weighing roughly 220 pounds. The advanced cooling technology integrated into these units employs a shock freezing method, bringing food temperatures down rapidly without compromising quality.

Energy efficiency is another essential feature of modern 5 tray blast chillers. They generally boast ratings significantly better than traditional freezers, promoting not just sustainability but also cost savings over time. Furthermore, user-friendly interfaces, including intuitive control panels, allow for easy temperature adjustments and cycle selection.

Benefits of using a 5 tray blast chiller in your business

Incorporating a 5 tray blast chiller into your food prep workflow brings numerous benefits, chiefly in enhancing food safety practices. The quick cooling process dramatically reduces the time food spends in the 'danger zone' where bacteria thrive, thus offering a safer environment for food storage.

Not only does blast chilling improve safety, but it also preserves the quality, flavor, and textures of chilled foods. Food retains its moisture and freshness, critical for restaurants aiming to deliver high-caliber dishes. The cost-effectiveness of these chillers is also notable, as properly chilled and stored food leads to less waste and allows operation costs to manage better.

Moreover, compliance with health regulations is simplified; implementing a blast chilling process can ensure businesses meet stringent food safety and handling standards.

How to operate a 5 tray blast chiller

Operating a 5 tray blast chiller involves a straightforward setup process: begin by ensuring that the chiller's installation meets kitchen layout and local safety codes. Next, configure the initial settings, ensuring that electrical requirements are met and all food safety protocols are in place.

After installation, selecting the appropriate blast chill cycle is vital. Different types of food may require tailored settings; for instance, seafood should be cooled faster than starchy items like bread. Regular maintenance checks are essential—this includes cleanliness inspections, as hygiene directly affects food safety, and ensuring that the blast chiller sensors and components are functioning optimally.

Innovative uses for 5 tray blast chillers

5 tray blast chillers are incredibly versatile, allowing operators to chill a wide array of food items efficiently. For example, meats and seafood benefit significantly from rapid chilling, extending shelf life and quality. Pastries and baked goods can also be blast chilled to maintain perfect texture and taste when served fresh.

Additionally, soups and sauces can be prepared and cooled quickly, ensuring peak flavor and nutritional integrity. Certain culinary practices, such as sushi preparation, may require customized chill times to adhere to specific standards, showcasing the flexibility of these chillers in meeting diverse kitchen needs.

Comparative analysis

When comparing 5 tray blast chillers to other chilling equipment, several factors emerge. The multi-tray capacity allows for simultaneous chilling, which significantly boosts efficiency compared to single-tray models. In contrast to larger multi-tray systems, the 5 tray option strikes an ideal balance for mid-sized operations looking for effective and space-saving solutions.

Top brands in the market include Foster, MAK, and Hobart, known for their reliability and innovative technology. Each offers distinct features, yet the 5 tray model often stands out due to its combination of size and functionality.

User experience and testimonials

Culinary professionals nationwide endorse the effectiveness of 5 tray blast chillers. Many restaurant owners report enhanced operational efficiency and the ability to manage higher volumes of food without compromising safety or quality. One notable case study involves a mid-sized restaurant that experienced a 30% reduction in food waste after integrating a blast chilling system.

Feedback highlights that the blast chiller's user-friendly interface simplifies the chilling process, making it accessible even for those with minimal technical training. Success stories circulate in industry circles, pointing towards increased uptake of 5 tray chillers as businesses look to optimize food preservation methods.

FAQs on 5 tray blast chillers

Potential users frequently ask about the blast chilling process and its workings. Essentially, the chilling mechanism rapidly cools food from room temperature to safe refrigeration levels, inhibiting bacteria and preserving texture. Other common queries pertain to the ability to adjust settings for different types of food, which is entirely feasible with modern models.

In terms of warranty and support, most manufacturers offer extended warranties, and thorough customer service to assist with setup and queries, ensuring that users can maximize their investment.

Downloadable resources

To facilitate your experience with 5 tray blast chillers, pdfFiller provides several downloadable resources. This includes a technical data sheet that outlines specifications, operational capacity, and energy efficiency ratings. There is also a product comparison sheet that allows potential buyers to assess various models against their needs.

Additionally, a maintenance checklist is available for download, helping kitchen staff stay organized and proactive in maintaining the performance and hygiene of their blast chillers.

Discover more with pdfFiller

pdfFiller not only aids in optimizing your culinary operations through the use of high-quality chilling equipment but also enhances document management for your restaurant. Seamlessly edit, eSign, and collaborate on critical documents from a single, cloud-based platform.

With access to templates for maintenance logs and compliance checklists, pdfFiller empowers restaurant owners and operatives to maintain high operational standards while ensuring the efficiency of their businesses.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I execute 5 tray blast chillershock online?

How do I edit 5 tray blast chillershock online?

How do I edit 5 tray blast chillershock in Chrome?

What is 5 tray blast chillershock?

Who is required to file 5 tray blast chillershock?

How to fill out 5 tray blast chillershock?

What is the purpose of 5 tray blast chillershock?

What information must be reported on 5 tray blast chillershock?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.