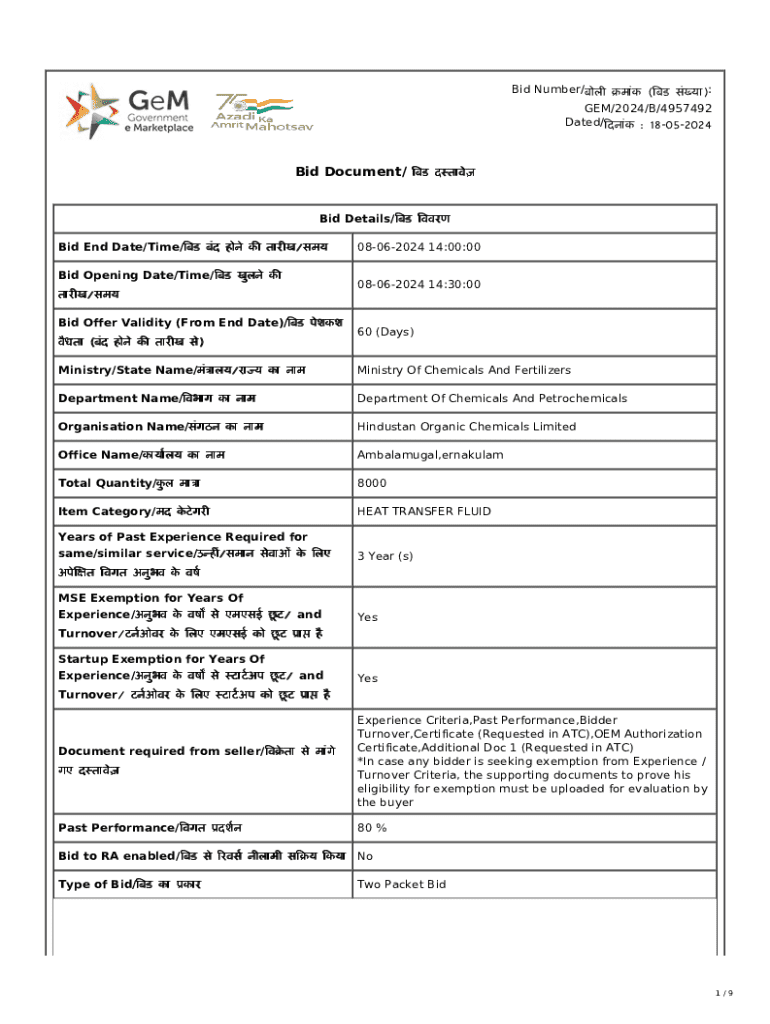

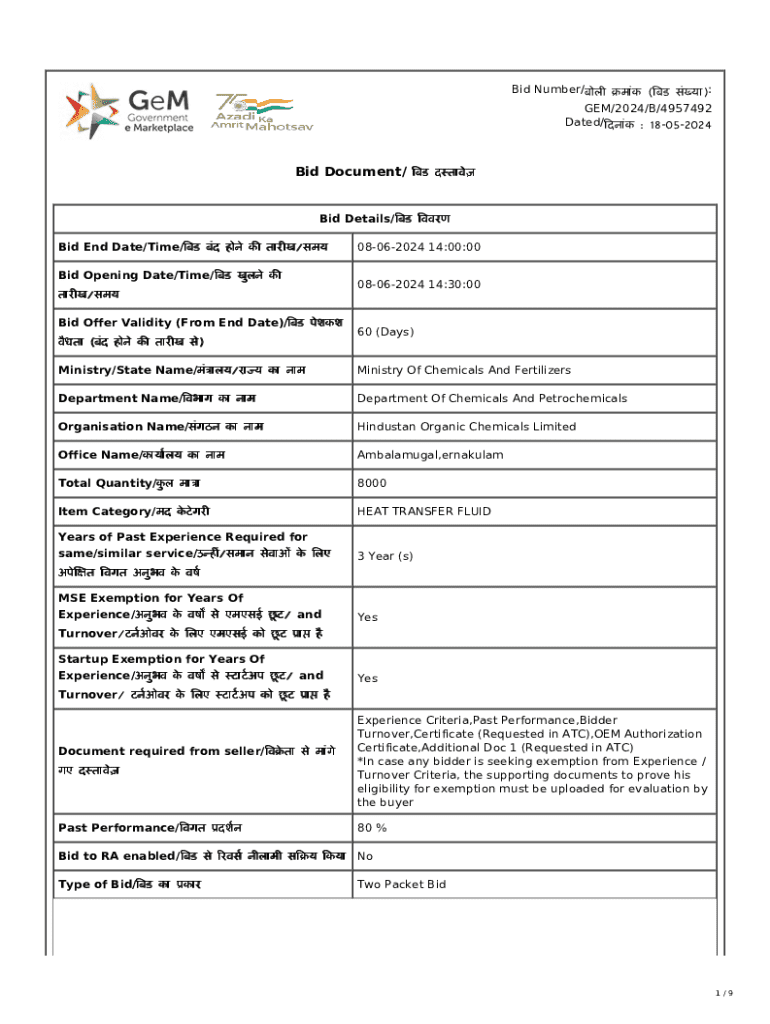

Get the free HEAT TRANSFER FLUID

Get, Create, Make and Sign heat transfer fluid

How to edit heat transfer fluid online

Uncompromising security for your PDF editing and eSignature needs

How to fill out heat transfer fluid

How to fill out heat transfer fluid

Who needs heat transfer fluid?

Understanding Heat Transfer Fluids: A Comprehensive Guide

Overview of heat transfer fluids

Heat transfer fluids (HTFs) are essential substances used to transfer heat from one place to another, playing a pivotal role in various thermal management systems. These fluids are designed to absorb heat, circulate, and release it efficiently within different industrial processes. Their primary importance lies in maintaining optimal thermal conditions for equipment and processes, enhancing performance and safety.

Common applications of heat transfer fluids span across various sectors, including manufacturing, chemical processing, HVAC systems, and renewable energy sectors such as solar thermal energy. Their crucial role in energy efficiency and heat management can significantly improve the overall effectiveness of production systems.

Types of heat transfer fluids

Heat transfer fluids can be categorized into several prominent types, each possessing unique characteristics and applications. Understanding these categories is crucial for selecting the right fluid suited for specific thermal tasks.

Choosing among these options depends on specific requirements such as temperature range, fluid stability, and application compatibility.

Characteristics of effective heat transfer fluids

An effective heat transfer fluid must exhibit several key characteristics for optimal performance. Understanding these characteristics can aid in selecting the right fluid for various industrial applications.

By assessing these characteristics, businesses can ensure they choose HTFs that meet their specific operational needs and contribute to efficient thermal management.

Industrial applications of heat transfer fluids

Heat transfer fluids have broad applications across numerous industries, each benefiting significantly from their efficiency and reliability.

The diversity of applications illustrates how integral HTFs are to modern industrial processes and energy management.

Factors to consider when choosing a heat transfer fluid

Selecting the appropriate heat transfer fluid requires careful consideration of several critical factors that influence both performance and safety.

Taking the time to thoroughly assess these factors will ensure effective system design and optimal fluid selection.

Heat transfer fluids in solar energy

In solar energy applications, heat transfer fluids are fundamental for efficiently capturing and transferring solar heat to generate power or provide thermal energy.

Innovative HTF solutions continue to evolve, promoting better efficiency in harnessing solar energy for everyday use.

Filling out the heat transfer fluid form: Step-by-step instructions

Completing the heat transfer fluid form accurately is crucial for ensuring the right fluid is selected for your application. Follow these steps to streamline the process.

By following these steps, you can fill out the heat transfer fluid form efficiently while ensuring all critical information is captured.

Managing and editing your heat transfer fluid form

Utilizing pdfFiller's platform to manage your heat transfer fluid form provides several advantages for document editing and collaboration. Here's how you can effectively use these tools.

These features make managing the heat transfer fluid form simpler and more efficient, positioning pdfFiller as an essential tool for document handling.

Common mistakes to avoid when filling out the form

Filling out the heat transfer fluid form correctly is vital for ensuring the effectiveness of fluid selection. Here are some common mistakes to avoid.

Avoiding these mistakes contributes to selecting the most appropriate heat transfer fluid and optimal system performance.

Importance of regular fluid condition checks

Regularly checking the condition of heat transfer fluids is crucial for maintaining system efficiency and effectiveness. Monitoring fluid quality allows for early detection of degradation, ensuring continued optimal performance.

By implementing regular checks, companies can safeguard against fluid-related downtimes and enhance the longevity of their thermal systems.

Industry trends and innovations in heat transfer fluids

The field of heat transfer fluids is continually evolving, driven by research and advancements in technology. Emerging trends focus on enhancing fluid performance and addressing environmental concerns.

Remaining informed of industry trends will enable businesses to adapt to changing technologies and stay ahead in their operational effectiveness.

Frequently asked questions about heat transfer fluids

As companies and individuals engage with heat transfer fluids, several common queries often arise regarding their selection and application.

Addressing these FAQs can guide best practices in fluid management, ensuring informed decision-making.

Get in touch with the heat transfer experts

For further guidance on heat transfer fluids, consulting with experts in the field can provide invaluable benefits. Engaging with knowledgeable professionals can streamline your selection process and ensure compliance with industry standards.

By leveraging expert insights, you can enhance both efficiency and safety in your heat transfer applications.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Where do I find heat transfer fluid?

How can I edit heat transfer fluid on a smartphone?

How do I fill out heat transfer fluid using my mobile device?

What is heat transfer fluid?

Who is required to file heat transfer fluid?

How to fill out heat transfer fluid?

What is the purpose of heat transfer fluid?

What information must be reported on heat transfer fluid?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.