Get the free Magnetic Particle Brakes, Clutches & Torque Limiters

Get, Create, Make and Sign magnetic particle brakes clutches

How to edit magnetic particle brakes clutches online

Uncompromising security for your PDF editing and eSignature needs

How to fill out magnetic particle brakes clutches

How to fill out magnetic particle brakes clutches

Who needs magnetic particle brakes clutches?

Magnetic Particle Brakes and Clutches Form: A Comprehensive Guide

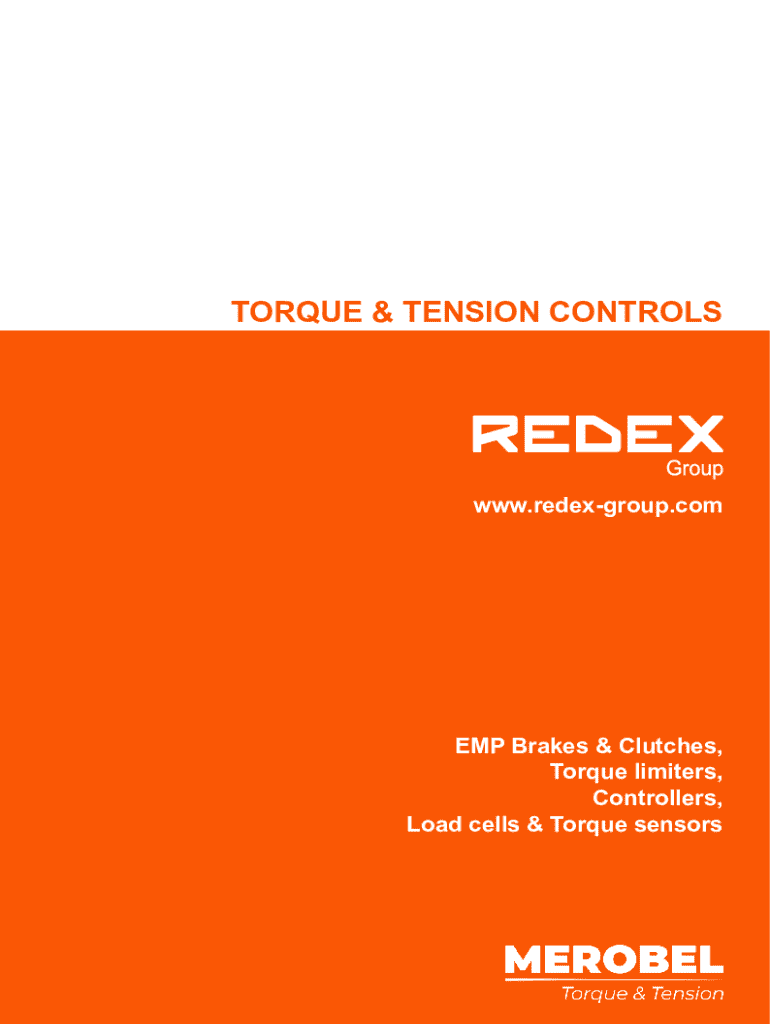

Understanding magnetic particle brakes and clutches

Magnetic particle technology involves using ferromagnetic particles suspended in a carrier fluid to create adjustable resistance. This innovative method has transformed how we approach braking and clamping systems, making them more efficient and adaptable. The essence of magnetic particle brakes and clutches lies in their ability to provide controlled engagement and disengagement, which is crucial in executing precise movements in machinery and vehicles.

These systems are essential in a range of applications, from industrial machinery to automotive engineering, where traditional methods might prove too rigid or inefficient. By allowing for variable torque control, magnetic particle brakes and clutches enhance performance while reducing wear and tear on components, making them an invaluable addition to modern engineering solutions.

Key components of magnetic particle systems

Understanding the fundamental components of magnetic particle systems is crucial for grasping how they function. Three primary components make up these systems: iron powder, electromagnetic coils, and control units.

Together, these components work in harmony to deliver responsive braking and clamping, enhancing the reliability and safety of modern machinery.

How magnetic particle brakes and clutches operate

The operation of magnetic particle brakes and clutches centers around the principle of magnetic attraction and repulsion. When electrical current is applied to the coils, the magnetic powder becomes magnetized, forming a 'fluidic' magnetic circuit that alters the torque transmitted through the system.

This method allows for incredibly refined control over torque transmission. As the intensity of the current increases, the density of the magnetic flakes increases, thus allowing for a stepless adjustment of the output torque based on real-time operational demands. This variability essential in applications requiring precise movements, enabling smoother operations and reducing mechanical stress on components.

Features of magnetic particle brakes and clutches

Magnetic particle brakes and clutches are renowned for several impressive features that set them apart from traditional systems. Key features include:

These features create a compelling case for integrating magnetic particle systems into any application requiring reliable and versatile torque management.

Comparative analysis: magnetic particle vs. other braking and clutching technologies

When evaluating braking and clutching technologies, it's essential to compare them against alternatives to understand their advantages and potential limitations. Common alternatives include hysteresis brakes and standard disc brakes.

While magnetic particle technology can be more complex, it significantly outperforms alternatives in terms of efficiency, maintenance, and operational flexibility. However, the initial investment and complexity of setup can be viewed as disadvantages, necessitating careful consideration of application needs.

Applications of magnetic particle brakes and clutches

The versatility of magnetic particle brakes and clutches makes them advantageous across various industries. Notably, applications include robotics, conveyor systems, and automotive systems.

Moreover, growth in electric and hybrid vehicle technology indicates new opportunities for magnetic particle systems, paving the way for sophisticated braking solutions in innovative mobility applications.

Technical specifications and selection criteria

When choosing a magnetic particle brake or clutch system, it is critical to assess key specifications to ensure optimal performance. Notable specifications include load capacity, response time, and operating environment.

To choose the right system, first assess your application needs in terms of torque requirements and environmental challenges, then review various manufacturers to find a system suited to your specific demands.

Maintenance and troubleshooting

To ensure the long-term reliability of your magnetic particle brake or clutch, regular maintenance is vital. Recommended practices include monitoring system performance, checking for wear on components, and ensuring the proper operation of control units.

If persistent issues arise, consulting a professional can help diagnose and rectify more complex problems effectively.

Unique benefits of using pdfFiller for documentation

In the context of managing documentation related to magnetic particle brakes and clutches, using pdfFiller provides unique advantages. Accurate documentation is essential for installation, maintenance, and compliance with safety standards.

By utilizing pdfFiller, teams can streamline their documentation process, ensuring they remain organized and prepared for any operational challenges.

Case studies: Successful use of magnetic particle systems

Several case studies highlight the effectiveness of magnetic particle technology in operational scenarios. For example, one robotics company integrated a magnetic particle clutch into their assembly line, reducing cycle times by 20% due to the improved speed control and precision.

Similarly, a conveyor manufacturer adopted magnetic particle brakes in their systems, resulting in a 15% decrease in energy consumption while enhancing load handling capabilities. These real-world examples underscore how magnetic particle systems can solve specific challenges, improving operational efficiency.

Frequently asked questions about magnetic particle brakes and clutches

As you navigate the world of magnetic particle technology, several common queries can arise. From understanding their operational benefits to clarifying their installation requirements, it’s important to address these effectively.

Expert insights can bring clarity and assist in making informed decisions tailored to your specific challenges, leading to enhanced performance in your operations.

Next steps for implementation

Once you've decided to implement a magnetic particle system, several next steps will aid in effective installation and usage. Begin with a thorough assessment of your installation environment to ensure compatibility with your chosen system.

By following these steps, you can ensure a smooth transition to using magnetic particle technology effectively and efficiently.

Interactive tools and resources

To facilitate your understanding and selection process further, several interactive tools and resources can provide added value in your journey with magnetic particle systems.

These tools empower users to make well-informed decisions, optimizing the advantages of magnetic particle technology in their operations.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I send magnetic particle brakes clutches for eSignature?

How can I get magnetic particle brakes clutches?

How do I execute magnetic particle brakes clutches online?

What is magnetic particle brakes clutches?

Who is required to file magnetic particle brakes clutches?

How to fill out magnetic particle brakes clutches?

What is the purpose of magnetic particle brakes clutches?

What information must be reported on magnetic particle brakes clutches?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.