Get the free Cut-Resistant Gloves and Sleeves - Ansell

Get, Create, Make and Sign cut-resistant gloves and sleeves

Editing cut-resistant gloves and sleeves online

Uncompromising security for your PDF editing and eSignature needs

How to fill out cut-resistant gloves and sleeves

How to fill out cut-resistant gloves and sleeves

Who needs cut-resistant gloves and sleeves?

The Essential Guide to Cut-Resistant Gloves and Sleeves Form

Understanding cut-resistant gloves and sleeves

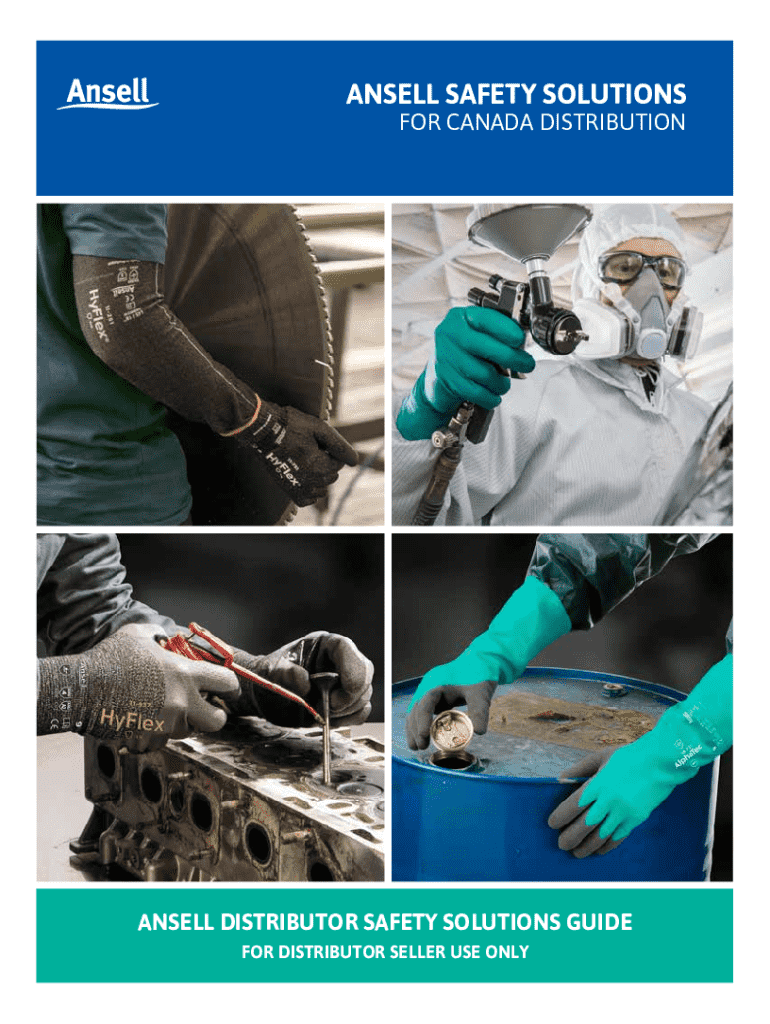

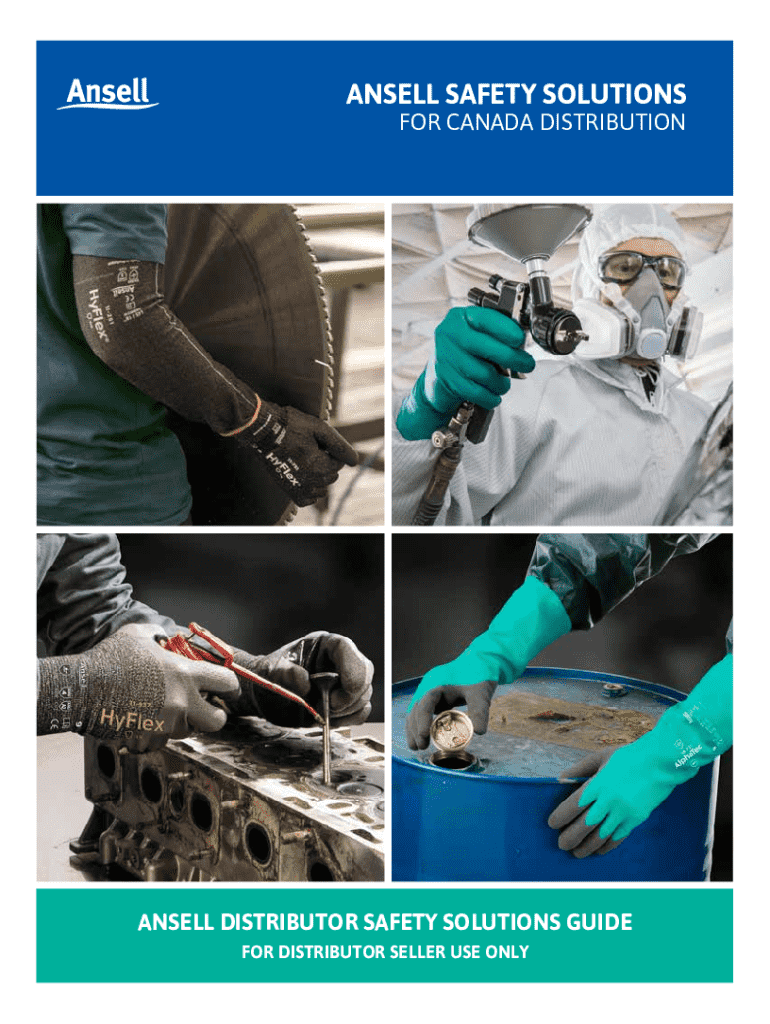

Cut-resistant gloves and sleeves are specialized protective wear designed to safeguard hands and arms against cutting hazards. These articles are essential for professionals who frequently handle sharp tools or materials, providing a tactical shield that prevents cuts and lacerations during various tasks. Their significance stretches across multiple industries, making them a staple in environments where the risk of injury from sharp objects is prevalent.

In industries like manufacturing, food processing, construction, and medical environments, the risk of cuts is markedly higher. For instance, in food processing, employees are at constant risk while using knives and machinery. Therefore, investing in cut-resistant gloves and sleeves is not just advisable but often a regulatory requirement to ensure workplace safety and compliance.

The science behind cut resistance

Understanding the science behind cut resistance involves examining the forces at play within cut-resistant materials. Two primary forces are acting on these gloves and sleeves: downward force (push) from cutting instruments and friction force (pull) as material is dragged across sharp edges. The effectiveness of cut-resistant gear relies heavily on material properties and the design features that mitigate these forces.

Different types of cutting hazards present in various workplaces can lead to different injury outcomes. For example, a straight, sharp object may cause linear cuts, while jagged edges can produce more severe lacerations. Superior cut-resistant materials counteract these forces through unique design features, including advanced layering techniques and high tensile strength fibers that provide durability while maintaining flexibility.

Materials used in cut-resistant gloves and sleeves

Cut-resistant gloves and sleeves are made using various advanced materials. Notable examples include Kevlar, Dyneema, and steel fibers. Each of these materials possesses unique properties that contribute to their cut resistance. Traditional materials like leather offer some level of protection but fall short compared to today's modern composites which are better suited for high-risk environments.

The gauge of cut-resistant gloves plays a significant role in their performance. Generally, a higher gauge denotes a finer knit, which can enhance dexterity, while still providing adequate cut resistance. Additionally, palm coatings such as polyurethane (PU), nitrile, and latex significantly influence cut resistance by improving grip and overall tactile feedback.

Industry standards and safety certifications

Understanding industry standards and safety certifications for cut-resistant gloves and sleeves is crucial for ensuring the protection they offer. The American National Standards Institute (ANSI) and the International Safety Equipment Association (ISEA) established the ANSI/ISEA 105 standard, which outlines testing methods and levels of cut resistance ratings. This empowers users to select the appropriate gear based on the specific risks they face.

In Europe, standards are governed by EN 388, which assesses the performance of protective gloves against mechanical risks. This standard provides essential labeling information, enabling users to make informed decisions about the cut protection level of gloves and sleeves. The UKCA marking further complements these certifications, ensuring compliance within the UK market post-Brexit.

Addressing limitations and misconceptions

While cut-resistant gloves and sleeves are essential for safety, it's important to acknowledge their limitations. Durability can be a concern; excessive wear or exposure to harsh conditions can diminish protective capabilities. It's also crucial to identify which environments and applications warrant their use, as improperly applied gear can lead to a false sense of security.

Several misconceptions surround cut-resistant wear, including the belief that higher cost correlates directly with better protection. In reality, the level of protection is determined by material quality and testing standards, not solely by price. Furthermore, not all gloves labeled as 'cut-resistant' offer the same degree of safety, and it's a common misconception that such gloves can prevent all hand injuries.

Selecting the right cut-resistant gloves and sleeves

Choosing the appropriate cut-resistant gloves and sleeves involves assessing several key factors including the type of work performed and the specific hazards present in your environment. Understanding the nature of the risks you face, alongside personal preference for fit and comfort, is paramount in making the right choice.

Certain features warrant particular consideration, such as grip and dexterity, essential for tasks that require precision. Cuff styles and sizes also play a crucial role in ensuring that the gloves and sleeves fit securely, preventing them from slipping or causing discomfort during use. Knowing the top-performing brands and models in the market further aids in informed decision-making based on real-world use-case scenarios.

How to properly use and maintain cut-resistant gloves and sleeves

Proper usage of cut-resistant gloves and sleeves is critical in maximizing their effectiveness. Ensuring the correct size and fit enhances comfort and safety, as ill-fitting protective gear can lead to accidents. Understanding when to wear gloves and sleeves, including situations where high-cut risks are present, is crucial in creating a safe working environment.

Maintenance practices also play an integral role in preserving the lifespan of cut-resistant wear. Regular cleaning according to manufacturer recommendations, along with awareness of signs of wear, helps in determining when to replace or repair your gear. Recognizing the longevity of materials allows for better planning and ensures ongoing protection.

Interactive tools and resources on pdfFiller

pdfFiller provides a range of interactive tools to enhance your documentation process related to cut-resistant gloves and sleeves. Fillable forms can assist in documenting workplace safety checklists, risk assessments, and more. This functionality allows users to create standardized safety procedures easily.

In addition to fillable forms, pdfFiller’s document management features enable users to collaborate on safety procedures efficiently. The ability to edit, eSign, and manage documents from a cloud-based platform streamlines workflows, ensuring compliance with health and safety regulations.

Safety education and training programs

Safety education and training programs are integral to creating a culture of safety when using cut-resistant gear. Educating workers about the correct usage of gloves and sleeves enhances overall safety and reduces the risk of injuries. A comprehensively trained workforce is better equipped to handle the challenges that come with high-risk industries.

Numerous resources exist for training materials and safety guides, empowering businesses to provide robust training for their personnel. Engaging in certification courses ensures that employees understand the importance of protective gear and the appropriate protocols for its usage.

Connect and engage with our community

Engaging with a community of users and safety professionals is a valuable way to share experiences and best practices related to cut-resistant gloves and sleeves. By joining discussions, individuals can learn from one another and improve safety protocols in their workplaces.

User testimonials and case studies further amplify understanding of the practical applications and benefits of cut-resistant gear. Connecting with support services within the pdfFiller platform can offer assistance in troubleshooting and document management, ensuring users get the most out of their safety equipment.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I get cut-resistant gloves and sleeves?

How do I edit cut-resistant gloves and sleeves straight from my smartphone?

Can I edit cut-resistant gloves and sleeves on an iOS device?

What is cut-resistant gloves and sleeves?

Who is required to file cut-resistant gloves and sleeves?

How to fill out cut-resistant gloves and sleeves?

What is the purpose of cut-resistant gloves and sleeves?

What information must be reported on cut-resistant gloves and sleeves?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.