Get the free Surface Finishing Mounted Interleaf Flap Wheels

Get, Create, Make and Sign surface finishing mounted interleaf

How to edit surface finishing mounted interleaf online

Uncompromising security for your PDF editing and eSignature needs

How to fill out surface finishing mounted interleaf

How to fill out surface finishing mounted interleaf

Who needs surface finishing mounted interleaf?

Surface Finishing Mounted Interleaf Form: A Comprehensive How-to Guide

Understanding surface finishing mounted interleaf forms

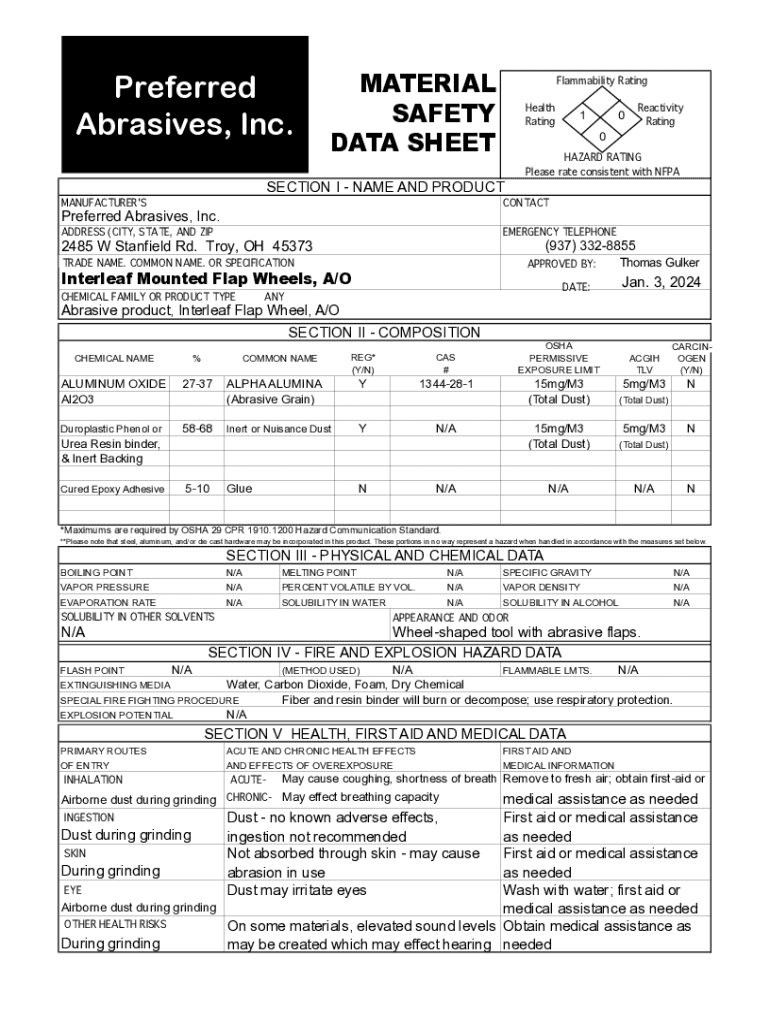

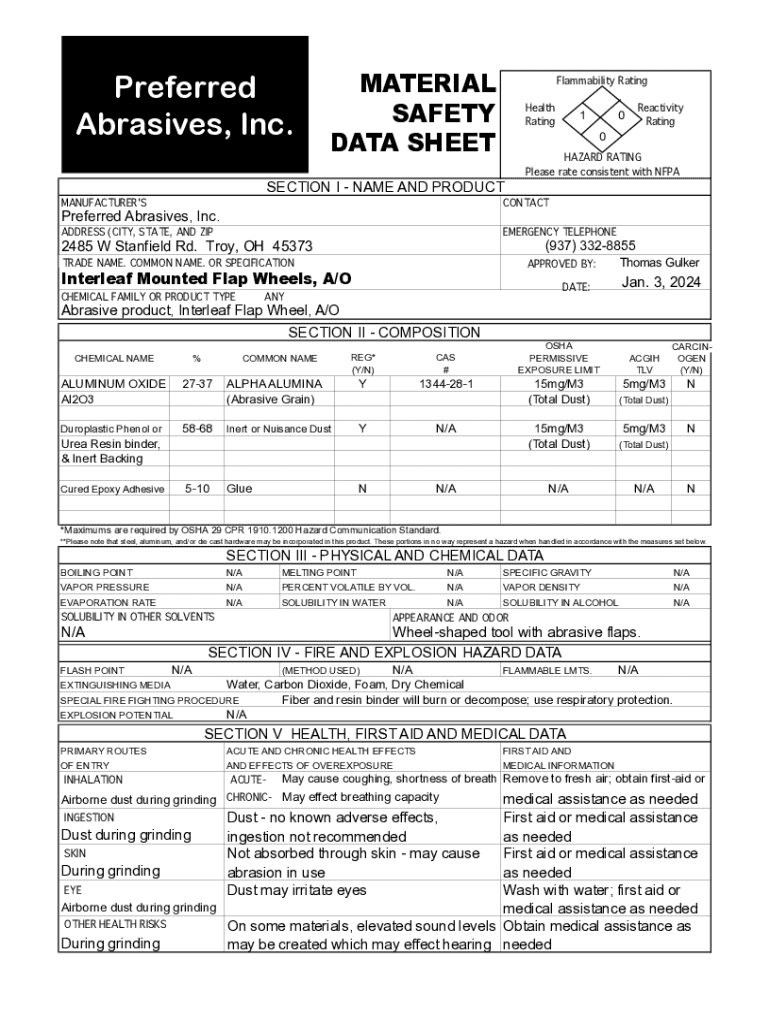

Surface finishing mounted interleaf forms are specialized tools designed to enhance the quality of surfaces in various materials. These forms typically consist of abrasive materials with an interleaf design that provides an effective abrasive action, crucial for achieving a smooth and polished finish. The primary purpose of these forms is to improve surface texture, remove imperfections, and prepare surfaces for further treatments such as painting, coating, or plating.

In surface finishing applications, the importance of mounted interleaf forms cannot be overstated. They play a vital role in industries such as metalworking, woodworking, and automotive, where precision and quality are paramount. The unique interleaf features, often crafted with an unbonded layer of material between the abrasive segments, allow for enhanced flexibility, ensuring thorough coverage while allowing for a better coolant flow during the finishing process.

Advantages of using mounted interleaf forms

Using mounted interleaf forms offers numerous benefits that enhance both the quality of work and the efficiency of the workflow. A primary advantage is the enhanced surface quality, providing a consistent finish that significantly reduces the likelihood of scratches, pits, and other imperfections. This is crucial in industries where aesthetic and surface integrity are essential.

Additionally, the versatility of these forms makes them suitable for various materials, including metals, plastics, and composites. This adaptability means that individuals and teams can employ the same tool across different projects, reducing the need for multiple tools and saving on costs. Furthermore, mounted interleaf forms accommodate both individual craftsmen and larger teams, streamlining projects and ensuring everyone can achieve a high-quality finish.

Choosing the right mounted interleaf product

Selecting the appropriate mounted interleaf product is critical to achieving optimal results during the finishing process. Key factors to consider include material compatibility, size and shape requirements, as well as grit and finish options. For instance, when working on a delicate metal surface, a finer grit may be necessary to avoid damage, whereas more robust materials might require a thicker, coarser grit.

When comparing products, interleaf flap wheels and interleaf brushes have distinct uses; flap wheels are typically better for flat surfaces, while brushes excel in hard-to-reach areas. Additionally, you may encounter mounted and non-mounted options. Mounted options offer more versatility in terms of their application on various tools, while non-mounted options can be better suited for stationary equipment.

Preparing for surface finishing

Preparation is key to a successful surface finishing project using mounted interleaf forms. Start by gathering essential tools and equipment, which may include power tools, safety gear, and various interleaf products. Ensure that your workspace is well-organized and free from unnecessary clutter to maintain focus and efficiency.

Safety precautions should not be overlooked; ensure proper ventilation if using powered equipment, and always follow equipment manufacturer guidelines. A well-prepared workspace not only enhances your productivity but also promotes safety, contributing to a more seamless finishing experience.

Step-by-step guide for using mounted interleaf forms

Following a structured approach when using mounted interleaf forms can greatly improve the efficiency and results of your surface finishing tasks. Begin with selecting the appropriate interleaf tool based on your project needs.

In step three, pay particular attention to applying the right amount of pressure. Excessive pressure may damage the material or the tool, while insufficient pressure can lead to ineffective finishing. Experimenting with speed settings on your equipment will also yield optimal results, allowing you to find the balance that works best for each material and tool combination.

Tips for achieving optimal results

To achieve the best possible results with mounted interleaf forms, adhere to certain recommended techniques and best practices. For example, always start with a clean surface; any contaminants can compromise the finishing process. Gradually progress through different grits, starting from coarse to fine, to blend inconsistencies effectively.

Remaining informed about common mistakes can save time and material. For instance, ensuring consistent speed and pressure across the workpiece helps avoid striations or uneven textures. If issues arise, promptly reevaluate your technique and tool settings to maintain quality throughout your project.

Enhancing workflow with technology

Efficient document management is an important yet often overlooked aspect of any finishing project. Utilizing platforms like pdfFiller can streamline your workflows by simplifying the way you create, edit, and manage documentation related to your surface finishing tasks. With features that allow for easy editing and eSigning of forms, you can enhance collaboration and documentation accuracy.

By leveraging technology, those involved in surface finishing can not only complete their projects more efficiently but also improve overall documentation practices. This becomes particularly valuable in industries where adherence to quality standards is essential.

Real-life applications and case studies

Mounted interleaf forms have found applications in a variety of industries. Case studies reveal their effectiveness in fields such as aerospace, automotive, and even dental laboratories where precision is key. For instance, in an automotive assembly line, the application of mounted interleaf forms has been crucial in ensuring that metal surfaces remain free from defects before painting, enhancing the aesthetic and functionality of the vehicles.

Testimonials from users frequently highlight the increased wow factor achieved through surface finishing with these tools—essential when gaining customer satisfaction. They note improvements in work output and product lifespan directly linked to rigorous surface finishing standards facilitated by mounted interleaf forms.

Frequently asked questions about mounted interleaf forms

It’s common for users to have questions about their mounted interleaf forms. One of the most asked questions is about the best materials suited for these products. Generally, mounted interleaf forms work exceptionally well with metals and plastics, each gaining specific benefits from the unique interleaf design.

Choosing the correct grit is crucial for ensuring that the finishing meets project specifications. Users frequently discuss their preferred maintenance practices, noting that keeping the tools clean and storing them appropriately helps significantly prolong the lifespan of mounted interleaf tools.

Related products and accessories

In the realm of surface finishing, a range of complementary tools and equipment can enhance your capabilities when working with mounted interleaf forms. Grinding wheels and cutting wheels pair well, offering additional options for material reduction before the finishing processes.

These products not only assist in achieving superior surface quality but also help streamline workflows. Choosing the right combination of tools can provide more efficient solutions to meet your surface finishing needs.

Getting support and expert advice

For those venturing into surface finishing with mounted interleaf forms, having access to expert advice can make a significant difference. Whether you're looking for assistance selecting the right tools or troubleshooting an issue, there are several support options available. Connecting with industry experts through various forums can provide valuable insights.

Utilizing these resources will empower you as you tackle your surface finishing projects, further enhancing your skills and improving your overall outcomes. With the combination of the right tools and expert support, you can ensure that you are well-equipped to achieve high-quality results.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I execute surface finishing mounted interleaf online?

How do I edit surface finishing mounted interleaf online?

How can I edit surface finishing mounted interleaf on a smartphone?

What is surface finishing mounted interleaf?

Who is required to file surface finishing mounted interleaf?

How to fill out surface finishing mounted interleaf?

What is the purpose of surface finishing mounted interleaf?

What information must be reported on surface finishing mounted interleaf?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.