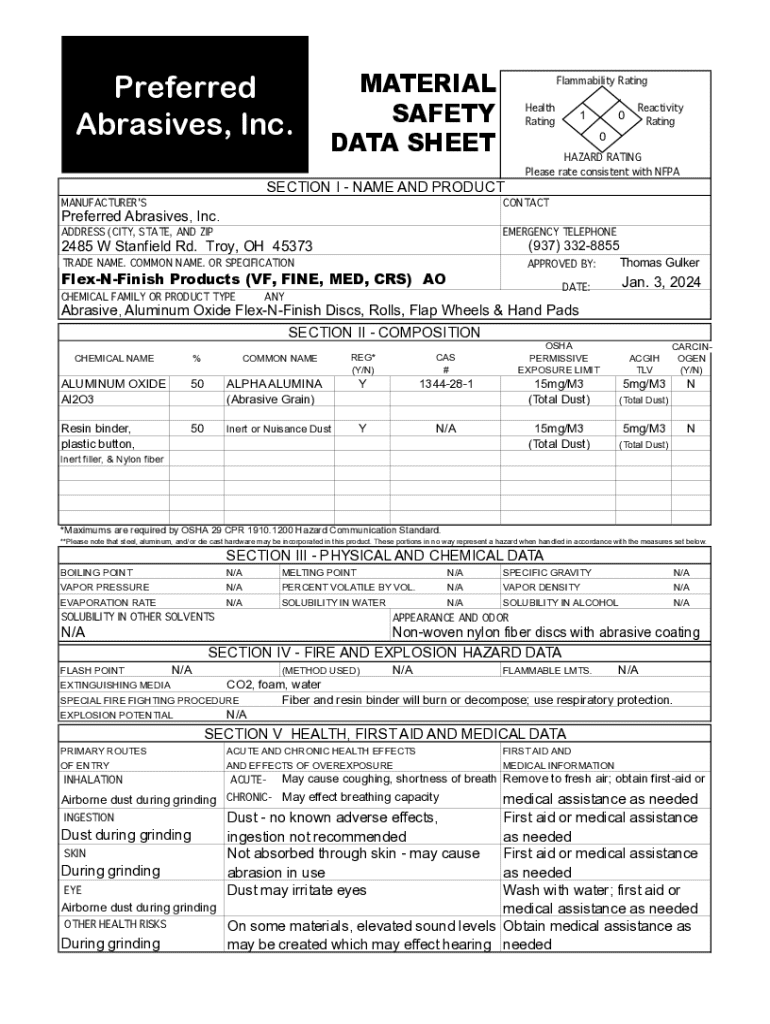

Get the free Flex-N-Finish Products (VF, FINE, MED, CRS) AO

Get, Create, Make and Sign flex-n-finish products vf fine

How to edit flex-n-finish products vf fine online

Uncompromising security for your PDF editing and eSignature needs

How to fill out flex-n-finish products vf fine

How to fill out flex-n-finish products vf fine

Who needs flex-n-finish products vf fine?

A Comprehensive Guide to flex-n-finish Products vf Fine Form

Understanding flex-n-finish products

Flex-n-finish products are specially engineered materials designed to adapt to various surfaces and applications, providing seamless finishes and efficient solutions across multiple industries. Known for their versatility, these products play a crucial role in ensuring smooth, aesthetically pleasing results in everything from DIY home projects to large-scale industrial applications. The demand for flex-n-finish products vf fine form has surged as users realize the convenience and effectiveness of these innovative solutions.

The importance of flex-n-finish products lies in their ability to enhance productivity and improve the quality of finishes, making them indispensable for both professionals and hobbyists. Their unique formulation allows for easy application and adjustments, catering to varying project requirements without sacrificing quality.

Applications of flex-n-finish products

Flex-n-finish products find extensive application across various sectors, proving their utility in both industrial and personal contexts. In manufacturing and production environments, these products streamline processes by delivering consistent finishes and reducing costly reworks. Their quick-drying properties allow for faster turnaround, benefiting industries where time is crucial.

Furthermore, on construction sites, contractors rely on flex-n-finish products to achieve high-quality aesthetic results that can also meet durability standards. From paint to caulking, these products enhance overall project quality while saving time and labor.

In the realm of DIY and home use, flex-n-finish products unleash creativity during home renovation projects. They provide the finishing touches that elevate aesthetics and can transform living spaces. Moreover, hobbyists and crafters can explore their artistic potential using these versatile materials, making everything from unique decor items to personalized gifts.

Choosing the right flex-n-finish product

Selecting the appropriate flex-n-finish product is crucial for achieving optimal results. Begin by evaluating your project requirements, which will help you determine the right product for your specific needs. Consider factors such as the surface type, desired finish, and environmental conditions that may affect the application.

Compatibility is also vital; ensure that the product you choose works harmoniously with existing materials. For example, using a finish not compatible with the base material can lead to poor adhesion or an undesirable outcome.

When comparing products, look at the different options available, including distinguishing features, benefits, and pricing. Many manufacturers offer detailed descriptions to help you make informed decisions.

Using flex-n-finish products effectively

Preparation is the first step toward effective application of flex-n-finish products. Begin by gathering all necessary tools and materials, including brushes, rollers, or spray equipment, depending on the product type. Proper surface preparation is essential; clean and sand the surface as needed to ensure a smooth application.

A detailed application process helps achieve a flawless finish. Start by applying the flex-n-finish product using proper techniques such as even strokes for paint or consistent pressure for caulking. Pay attention to detail and take your time to avoid mistakes.

Once the base application is complete, consider the finishing touches that can enhance the overall appearance. Techniques such as sanding for a smoother surface or adding a topcoat can contribute to a polished final result.

Post-application best practices

Maintaining the quality of your projects post-application is essential for long-lasting results. Routine checks and maintenance tips can keep your finishes looking fresh and vibrant. Regular inspections can help identify wear or damage early, allowing for timely interventions.

In the event of damage, knowing how to repair common issues is vital. Simple touch-ups or reapplications with flex-n-finish products can often restore the original appearance without extensive work.

Proper storage of flex-n-finish products contributes to their longevity. Store them in a cool, dry place and ensure lids are tightly sealed to prevent drying or contamination.

Troubleshooting common issues

Recognizing problems early in the application process can save time and materials. Some common mistakes include applying the product in unsuitable conditions, like high humidity or low temperatures, which can affect drying times and adhesion. Ensure that the surface is adequately prepared; failure to do so can lead to peeling or cracks.

Identifying potential issues early, such as bubbling or uneven finishes, allows you to adjust your technique promptly. Quick fixes can often resolve minor issues, such as lightly sanding and reapplying the product.

However, knowing when to seek professional help is essential. If problems persist or you encounter complicated issues, collaborating with an expert can save you time and ensure a high-quality finish.

Enhancing productivity with technology

In an increasingly digital environment, integrating technological tools can significantly increase productivity. Utilizing cloud-based platforms, like pdfFiller, facilitates the efficient management of project documentation, including storing project files, contracts, and specifications. This streamlined approach saves time and minimizes errors associated with paperwork.

Additionally, eSigning and collaboration tools foster seamless communication among team members and clients. Approval processes can be expedited, ensuring everyone is aligned on project developments without cumbersome meetings.

Interactive tools, such as online calculators and estimators, can further enhance productivity by providing quick assessments of project requirements. Templates for common applications ensure consistency across documentation, promoting efficiency throughout the project cycle.

User experiences and case studies

Numerous success stories highlight how individuals and teams have effectively utilized flex-n-finish products vf fine form. For instance, contractors in the Chicago area have successfully improved their project turnaround times by integrating these products, leading to increased client satisfaction and repeat business.

Feedback from users often cites improved ease of application and superior finishes as key benefits. Many have reported how the adaptability of flex-n-finish products allowed them to tackle a wide range of projects, from minor home improvements to major commercial endeavors.

Diverse use cases across industries demonstrate the broad applicability of these products. Craft enthusiasts and professional artists have effectively used flex-n-finish products for creating intricate designs, showcasing the potential for creativity that these materials unlock.

Future trends in flex-n-finish products

As industries evolve, the demand for flexible, high-performance materials like flex-n-finish products will continue to grow. Emerging technologies in manufacturing are poised to enhance product formulations, resulting in improved performance and broader applications. Innovations in the industry increasingly emphasize sustainability, leading to the development of eco-friendly variants of flex-n-finish products that satisfy environmental concerns.

Adaptability to market changes is crucial, especially as consumer preferences shift towards greater sustainability and efficiency. Keeping pace with these trends ensures that manufacturers remain competitive while addressing the specific cost and performance needs of their consumer base.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I make changes in flex-n-finish products vf fine?

How do I fill out flex-n-finish products vf fine using my mobile device?

Can I edit flex-n-finish products vf fine on an iOS device?

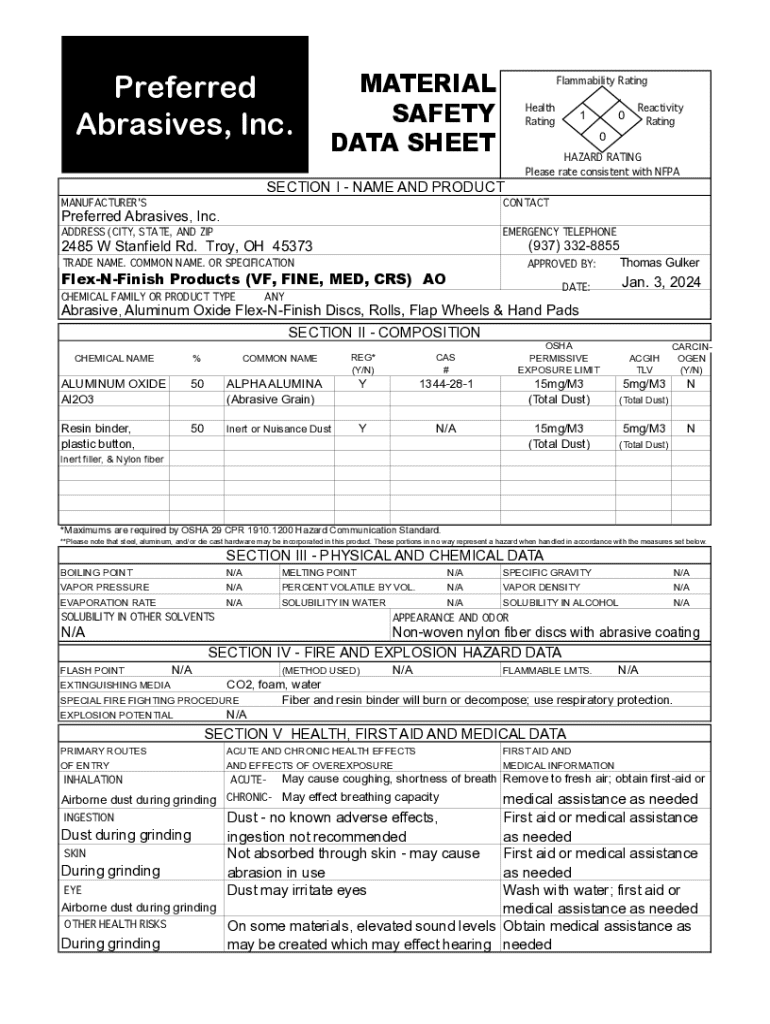

What is flex-n-finish products vf fine?

Who is required to file flex-n-finish products vf fine?

How to fill out flex-n-finish products vf fine?

What is the purpose of flex-n-finish products vf fine?

What information must be reported on flex-n-finish products vf fine?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.