Get the free DOUBLE WALL models - nothing but advantages!

Get, Create, Make and Sign double wall models

Editing double wall models online

Uncompromising security for your PDF editing and eSignature needs

How to fill out double wall models

How to fill out double wall models

Who needs double wall models?

Double wall models form: A complete guide to creating and utilizing double wall structures

Understanding double wall models form

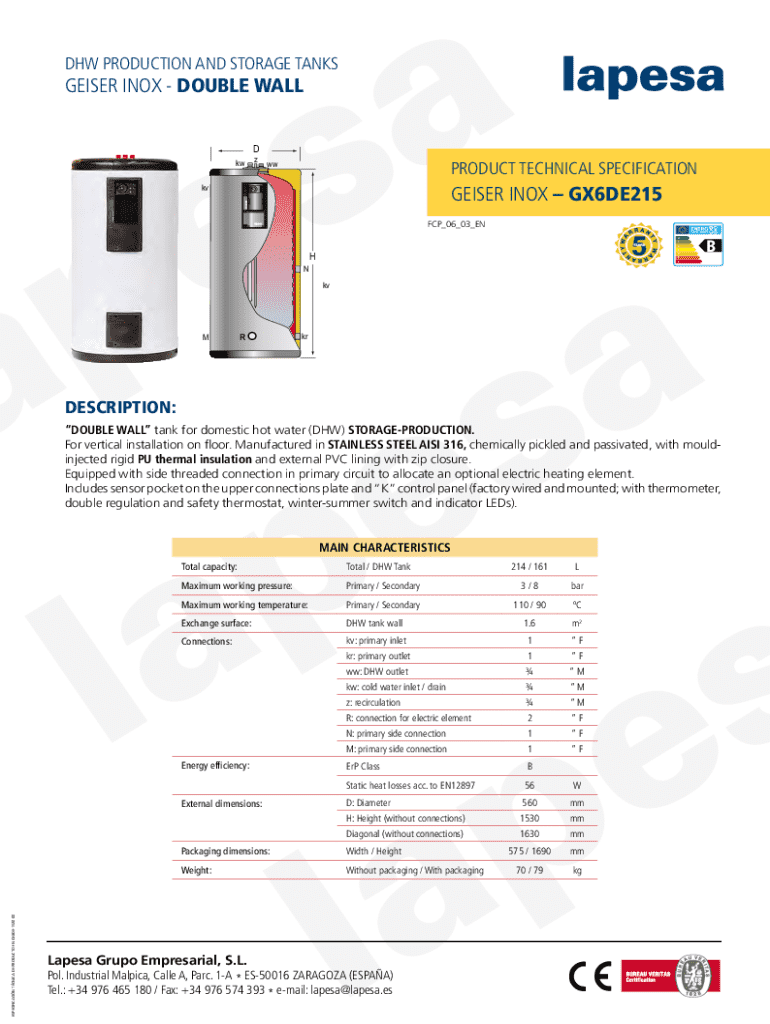

Double wall models, defined as structures consisting of two distinct layers with a space in between, play a crucial role in various fields, including pottery, manufacturing, and architecture. Their unique design allows for better insulation, durability, and aesthetic appeal, making them a favorite among artisans and industrial designers alike.

The importance of double wall models is evident in their multiple applications. In pottery, for instance, they enhance functional aspects such as thermal efficiency while also allowing for artistic expressions. In industrial settings, these models can streamline production processes and contribute to energy conservation strategies.

Preparing your workspace and materials

Creating double wall models requires a well-prepared workspace and the right materials. Essential tools for this process include cutting tools, molds, and carving knives, which enable precision in creating both the outer and inner layers of the model.

Material selection is critical as well. Choosing the appropriate clay or composite material directly influences the strength and aesthetic qualities of the final product. For example, stoneware clay adds durability, whereas porcelain may lend a more refined look and feel.

A clean and functional workspace is vital to ensure the successful creation of double wall models. Organizing tools and materials before starting will minimize distractions and streamline the modeling process.

Step-by-step guide to creating double wall models

Creating your double wall model involves several key stages, beginning with forming the outer layer. Techniques such as throwing on the potter's wheel or hand-building can be employed to shape this layer. When forming the outer layer, consider the wall thickness carefully; uneven walls can lead to structural issues.

Once the outer layer is complete, the next step involves preparing the inner layer. Techniques to create a consistent wall construction may include using a slab method or coiling, which ensures the integrity of the double wall design. It's essential to build appropriate inner support structures to maintain form during the drying and firing process.

Attaching the two layers is a critical final step. Methods like scoring and slipping can facilitate a seamless connection between the layers, while trimming excess material can enhance the overall appearance. Finishing touches may include smoothing edges and refining surface details.

Advanced techniques for enhancing double wall models

To take your double wall models to the next level, consider delving into advanced glazing processes. Selecting the right glaze is crucial; it not only adds visual appeal but also affects the durability of the final piece. Applying glazes can be done through various techniques including dipping, spraying, or brushing, followed by appropriate firing processes.

Additionally, enhancing volume and aesthetics in your models can make them stand out. Focus on design elements that emphasize volume, such as varied textures or color gradients. Experimenting with different forms and finishes will provide unique artistic outcomes, enriching your repertoire.

Troubleshooting common issues

Even seasoned artists encounter challenges when working with double wall models. One common issue is cracking and shrinkage during the drying and firing processes. Preventative measures include ensuring even wall thickness and controlling drying rates, while solutions for managing cracks often involve effective repair techniques such as using slip or clay patches.

Another issue is the integrity of joints between layers. Improving weak joints can be achieved through reinforcement methods, including the application of additional slip at attachment points and careful monitoring during the drying process to prevent separation.

Related types of double wall models

Double wall models also find applications in various fields beyond pottery. Ceramic and porcelain double wall forms are popular for their thermal properties, often used in innovative tableware design. In architecture, double wall systems are valued for their energy efficiency and sound insulation capabilities.

Moreover, modern design approaches have led to innovative crafting techniques that blend aesthetics and functionality in double wall models. This includes the integration of smart materials that can adapt to environmental factors, further expanding the potential applications for double wall designs.

Resources and tools for further learning

For those looking to deepen their skills in double wall modeling, numerous online resources are available. Websites often feature tutorials and workshops dedicated to the specific techniques and materials used in creating double wall structures, helping both beginners and seasoned artisans refine their craft.

Additionally, recommended books and reference materials can provide valuable insights into advanced techniques and innovative design principles. Engaging with communities and forums focused on pottery or manufacturing can also offer ongoing support and inspiration, providing a platform for exchanging ideas and challenges.

Legal and safety considerations

When creating double wall models, it's crucial to adhere to safety protocols, especially when working with materials that could pose health risks. Implementing proper ventilation and using protective gear, such as gloves and goggles, are essential practices to ensure a safe working environment.

Moreover, compliance with local regulations and standards is paramount, particularly in commercial contexts. Understanding product liability and safety regulations can help protect creators and ensure their designs meet necessary guidelines for quality and safety.

Glossary of terms related to double wall models

To assist both novice and experienced practitioners, a glossary of terms is helpful for understanding the technical language associated with double wall modeling. Familiar terms include 'thickness,' referring to the distance between the two walls of the model; 'slip,' denoting a wet clay mixture used for joining components; and 'firing,' which is the process of hardening the clay in a kiln.

Frequently asked questions (FAQs)

Many individuals have questions about double wall models, particularly beginners who may feel overwhelmed by the process. Common queries include how to prevent cracking during firing, the best clay types to use, and tips for attaching layers seamlessly.

Providing comprehensive answers to these questions can empower learners, ensuring they understand both the technical and creative aspects of double wall modeling. For instance, using a slow drying method can minimize cracking, and experimenting with various attachment techniques can significantly improve the result of their projects.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I modify my double wall models in Gmail?

Can I sign the double wall models electronically in Chrome?

How do I edit double wall models on an Android device?

What is double wall models?

Who is required to file double wall models?

How to fill out double wall models?

What is the purpose of double wall models?

What information must be reported on double wall models?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.